[introduction] painting as an important member of pressure vessel equipment, paint early mostly with vegetable oil as the main raw materials, so called “ &rdquo, such as health and environmental protection paint; raw cooked Tung oil. Whether the paint natural products as raw materials of the traditional or modern development in the synthesis of chemical products as raw materials of paint products are organic chemical coating formed by the polymer material, and belongs to the field of polymer type. According to the classification of modern chemical products, paint belongs to fine chemical products. Modern coatings are gradually becoming a kind of multifunctional engineering materials, which is an important industry in the chemical industry.

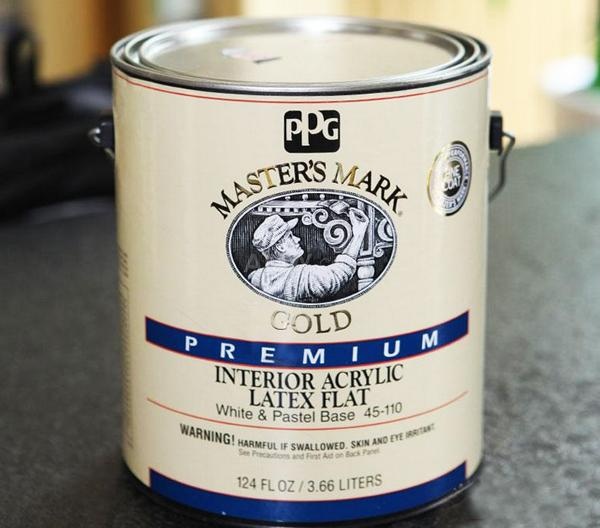

An acrylic latex paint

General consists of acrylic emulsion, acrylic pigment and filler, water and additives. The product has the advantages of moderate cost, good weather resistance, good performance, no organic solvent release, etc., and is a kind of coating product which has been developing very fast recently. Mainly used in the internal and external walls of the building coating, leather coating, etc.. Recently appeared for wood Selfcrosslinkable latex paint, latex paint and other new varieties. Acrylic emulsion paint according to the different emulsion can be divided into pure C, C, C, C, C, C and other varieties.

Two, solvent based acrylic paint

Solvent based acrylic paint with excellent weather resistance, high mechanical properties, is currently developing a fast class of paint. Solvent type acrylic paint can be divided into self drying acrylic paint (thermoplastic) and curing acrylic paint (thermoset), the former belongs to non conversion coatings, which belongs to the conversion coatings.

Self drying acrylic coatings are mainly used in architectural coatings, plastic coatings, electronic coatings, road marking paint, etc., with a fast, easy to do the work of construction, protection and decoration of the obvious advantages. The disadvantage is that the solid content is not easy to be too high, hardness, flexibility is not easy to take into account, a construction can not get a very thick film, film fullness is not ideal.

Crosslinking curing acrylic acid paint mainly has acrylic amino paint, acrylic polyurethane paint, acrylic acid alkyd paint, radiation curing acrylic paint and other varieties. Widely used in automotive coatings, wood coatings, architectural coatings, electrical coating etc.. Curing acrylic coating usually has high solid content, a coating film can be very thick, and excellent mechanical properties, can be made into high weatherability, high fullness, high elasticity, high hardness of coatings. Shortcomings of the two components coating, construction is more trouble, many varieties also need to heat curing or radiation curing, the requirements of environmental conditions are relatively high, generally require better equipment, more skilled painting skills.

Three, polyurethane paint

Polyurethane coatings is a common kind of coatings, which can be divided into two groups of polyurethane coatings and one component polyurethane coatings.

Two component polyurethane coatings are generally composed of two parts, which are isocyanate pre polymer (also called low molecular urethane polymer) and hydroxyl resin. There are many varieties of this type of coating, the application range is very wide, according to the different components of the hydroxyl group can be divided into acrylic polyurethane, alkyd polyurethane, polyester polyurethane, polyether polyurethane, epoxy polyurethane and other varieties. Generally have good mechanical properties, high solid content, all aspects of the performance are relatively good. Is a kind of paint variety which has a good future at present. The main application direction of wood coatings, automotive refinish coatings, anti-corrosion coatings, floor coatings, paint, paint and other special electronic. Disadvantage is the construction process is complex, the requirements of the construction environment is very high, the paint film is easy to produce ills.

Single component polyurethane coatings are mainly urethane oil paint, moisture curing polyurethane coatings, blocked polyurethane coatings etc.. Application is not as good as two-component coating, mainly used for floor coatings, anti-corrosion coatings, pre coil coating, etc., its overall performance is not as good as two component paint comprehensive.

Four, nitro paint

Lacquer is currently more common wood and decoration coatings. Advantages are good decoration, construction is simple, fast drying, the requirements of the coating environment is not high, with good hardness and brightness, not prone to paint film defects, easy to repair.

The disadvantage is low solid content, need more number of road construction can achieve good results; durability is not too good, especially in the lacquer, the gloss is not good, slightly longer prone to loss of light, such as cracking, discoloration and other ills of time; the film protective effect is not good, no organic solvent, no heat, no corrosion.

The main film forming material is mainly to nitrocellulose lacquer, with alkyd resin, rosin modified resin, acrylic resin, amino resin and other resin composed of hard and soft. The general need to add two octyl phthalate, dibutyl phthalate, oxidation of castor oil plasticizer. Solvent mainly esters, ketones, ethers and other true solvents, alcohol as solvent, benzene and other diluent. Lacquer is mainly used for wood and furniture, home decoration, decorative painting coating, metal coating, coating and other aspects of the general cement.

Five, epoxy paint

Epoxy paint is a very rapid development in recent years, a class of industrial coatings, in general, the composition of the coating containing more epoxy groups referred to as the epoxy paint.

The main varieties of epoxy paint are two-component coating, which is composed of epoxy resin and curing agent. There are a number of other single type of dry type varieties, but the performance of the two components of the paint compared to a certain gap. The main advantages of epoxy paint is the cement, metals and other inorganic materials has a strong adhesive force; the paint itself is very resistant to corrosion; excellent mechanical properties, abrasion resistance and impact resistance; can be made without solvent or high solid coatings; solvent resistance, heat resistance, water resistance; non toxicity.

The disadvantage is not good weatherability, sunlight for a long time may appear chalking phenomenon, which can only be used in primer or paint decoration; poor luster is not easy to maintain; high requirements for construction environment, low temperature curing of coating is slow, the effect is not good; many varieties of high temperature curing coating equipment, large investment. Epoxy resin coatings are mainly used in floor coating, auto primer, metal corrosion, chemical corrosion and so on.

Six, amino paint

Mainly consists of two parts: one is the amino paint, amino resin component, mainly butylated melamine formaldehyde resin, melamine formaldehyde resin ether, butylated urea resin resin. The second is the hydroxyl resin, mainly in the short oil alkyd resin, acrylic resin, epoxy resin, etc.. In addition to the UF resin paint paint coatings (commonly known as acid curing paint), the main varieties are generally need heating and curing, curing temperature is over 100 DEG C, the curing time in more than 20 minutes.

After curing the film performance is excellent, the film is hard and plump, bright and gorgeous, strong and durable, with a good decorative effect and protective effect. The disadvantage is that the requirements of coating equipment is higher, energy consumption is high, is not suitable for small production. Amino paint is mainly used for coating automobile paint, furniture painting, household appliances, metal coating, painting a variety of instruments and industrial equipment.

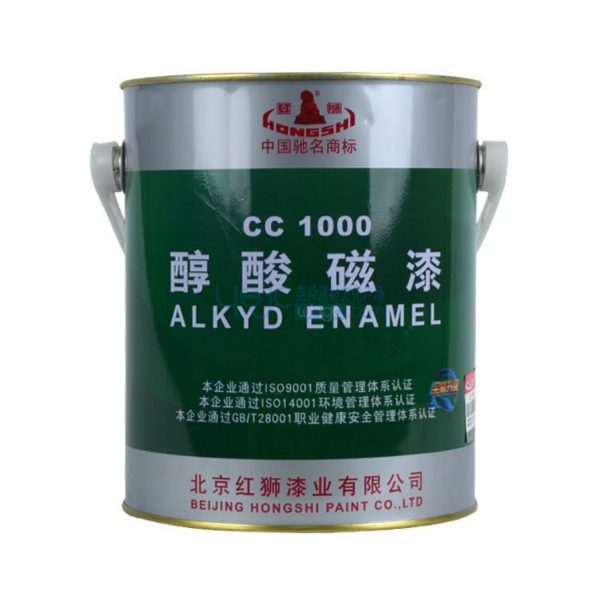

Seven, alkyd paint

Alkyd paint is mainly composed of alkyd resin. Is currently the largest domestic production of a class of paint. The film has the advantages of cheap price, simple construction, low requirements for the construction environment, hard coating, good durability, good weather resistance, good decoration and protection. The disadvantage is that the drying is slow, the coating is not easy to achieve high requirements, not suitable for high decorative occasions. Alkyd paint is mainly used for coating general wood, furniture and home decoration, metal decorative painting, requirements of the metal anti-corrosion coating, general machinery, automotive, instrumentation, industrial equipment, coating etc..

Eight, unsaturated polyester paint

Unsaturated polyester paint is also a fast development of a class of coatings, is divided into two types of dry unsaturated polyester and radiation curing (light curing) unsaturated polyester.

The main advantage is that it can be made into a solvent free coating, the coating can be a thick film, the requirements of the coating temperature is not high, and the paint film decoration effect is good, the film is tough and wear-resistant, easy to maintain.

The disadvantage is the larger shrinkage of cured film, adhesion to the substrate is prone to problems, the air drying unsaturated polyester generally need polishing, procedures are more cumbersome, radiation curable unsaturated polyester coating equipment for higher requirements, not suitable for small production. Unsaturated polyester paint is mainly used for furniture, wood flooring, metal corrosion, etc..

Nine, vinyl paint

Vinyl paint including vinyl chloride vinyl acetate copolymer resin paint, paint, poly vinylidene chloride, vinyl chloride, chlorosulfonated polyethylene paint etc.. The main advantage of vinyl paint is weathering resistance, chemical corrosion resistance, water resistance, insulation, anti mildew, good flexibility. The disadvantages are mainly manifested in heat resistance, not easy to make high solid paint, mechanical properties in general, poor decorative performance. Vinyl paint is mainly used in industrial anticorrosive coatings, electrical insulation coatings, phosphating primer, metal coatings, external coatings, etc..

Ten, phenolic paint

Phenolic resin is phenol and formaldehyde in the presence of condensation products, paint industry are mainly used in the oil soluble phenolic resin paint. Phenolic paint has the advantages of fast drying, bright and hard paint, water resistance and chemical resistance is good. The disadvantage is that it is easy to turn yellow, it is not easy to make light color paint, weather resistance is not good. Phenolic paint is mainly used in anti-corrosion coatings, insulation coatings, general metal coatings, general decorative coatings, etc..

Process equipment network finishing release, reproduced please indicate the source.