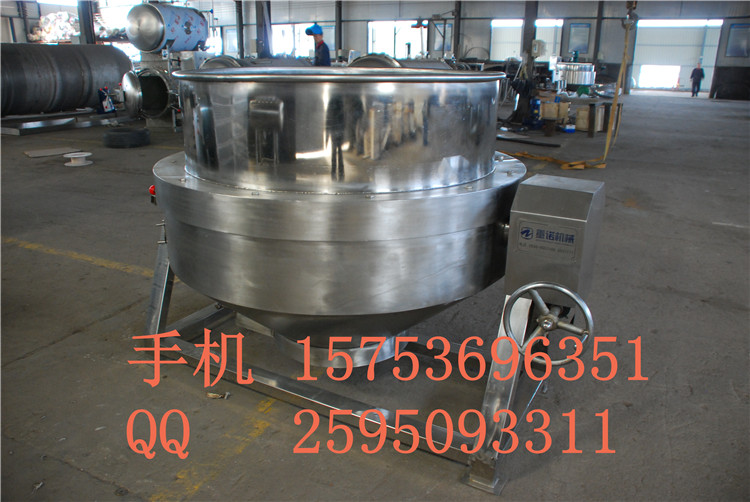

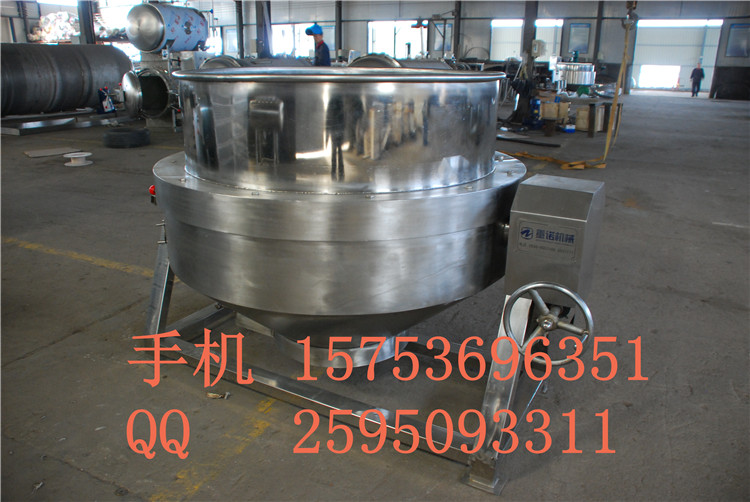

Gas pot sandwich sandwich pot braised pork sandwich pot bittern food price is already very common in our life, like meat, chicken and other bittern bittern. But with the traditional big pot burning firewood, the labor force often does not speak. It often causes the heat to be unstable, or it is too bad to cook, or it is not hot enough to eat. It is difficult to eat, the production environment is not clean, and the hygienic conditions are not up to standard. This is to use the sandwich pan, the sandwich pan is easy to use, clean and easy to operate. Is your best choice of ingredients bittern.

Installation steps of gas-fired sandwich pan

1. The gas-fired sandwich pan should be installed in a well ventilated environment when installed. The ground is flat, the operation space is open, the installation and adjustment of the equipment are stable, and the anchor bolts can not be loosened.

2, the bolt on both sides of the supporting frame should be tightened, and when the pot body is tilted, the inlet and outlet pipe at both ends of the pot body can not be transferred with the pot body.

3, when the gas is in, the screw should be tightened if the joint is leaking at the butt joint until the gas does not leak.

4. A gutter or a geosyncline which will have a smooth drainage in the gas intercalation pot equipment is needed. It is convenient for the production to be used when the water is added or the pot body is used when the production is stopped.

5, the gas pressure should be adjusted before use, and the dynamic pressure of the surrounding gas appliances at the same time should be conformed to the requirements.

Cautions for the use of gas-fired intercalation cooker

1, gas intercalation pot in the production of the working site, to have a certain ventilation facilities to maintain a good ventilation environment.

2, before each production, the gas pipeline and valve should be checked to prevent gas leakage, causing gas poisoning or fire accidents.

3, check the seal of each joint at regular intervals. Keep the stove clean, prevent the production of the material to drop the stove hole blocking plug.

4. Turn off the gas when the material is leaning and turn off the speed control switch.

5, the burner can only use liquefied gas and natural gas to remember that all other gases are not to be used.

6, in the production process, we must ensure that the gas pressure is within the normal range. If it is not in the normal range, it will cause insufficient combustion gas, which will increase the possibility of gas poisoning for operators.

7, the pipe and valve connecting the stove will be screwed to the dead surface naturally and keep a safe distance, so as to avoid the accident caused by my scorching.

8. Do not place articles around the gas intercalation pan so as not to cause a fire.

9, after the end of the work, the gas valve and the front switch must be closed and tightened to prevent the accident.

10, tilting and stirring the pot sandwich, no boot should be used in various rotating parts grease. A part on the body of a stirred sandwich pan.

11, clean up the domestic and join the material. The heat transfer oil is added to the power supply. When the material reaches the required temperature and the heating time is reserved, turn off the power supply. Turning to the handwheel will tilt the pot into the discharge.

12. The PT100, a temperature sensor behind the pot, is used to measure the temperature of the heat conduction oil. The set temperature is measured by the electronic control box and will not continue to be heated when the set temperature is exceeded. It will continue to be heated when it is below the set temperature.

13. In the process of operation, the temperature should be strictly controlled. Under the general condition, the temperature control should be used below 200 degrees.