1. overview

Strong inorganic acids (phosphoric acid, sulfuric acid, nitric acid) are often used to remove surface oxides in the finishing industry of aluminum alloy surface treatment to reduce the impact on subsequent production operations. To a large extent, these oxides are dissolved by acid, and the concentration of free acid decreases with the increase of the surface treatment concentration of dissolved aluminum alloy. Although new acids can be added to the solution to make up for this, the oxide removal rate (pickling) usually decreases as the surface treatment concentration of the aluminum alloy increases. When the scale is no longer sufficiently removed, the acid must be poured out.

This method of operation can cause productivity related problems. A newly formulated acid bath with a low dissolved iron content is very strong and may result in over pickling. Unqualified materials close to scrap due to pickling may also be produced. Rework may be necessary to prevent subsequent surface treatment process problems.

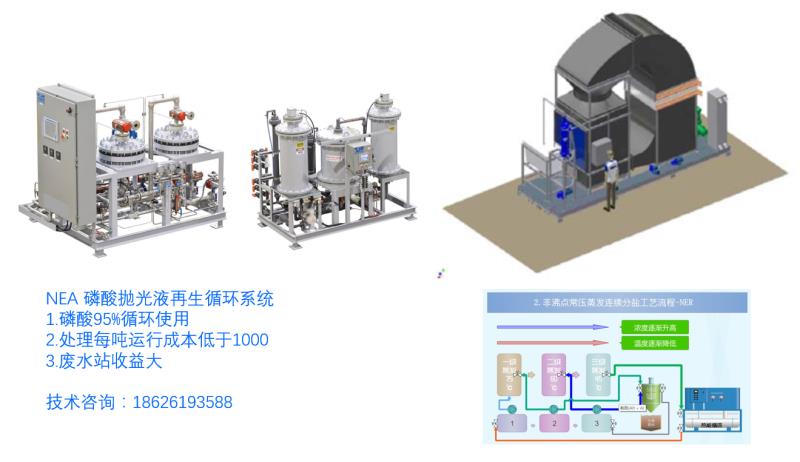

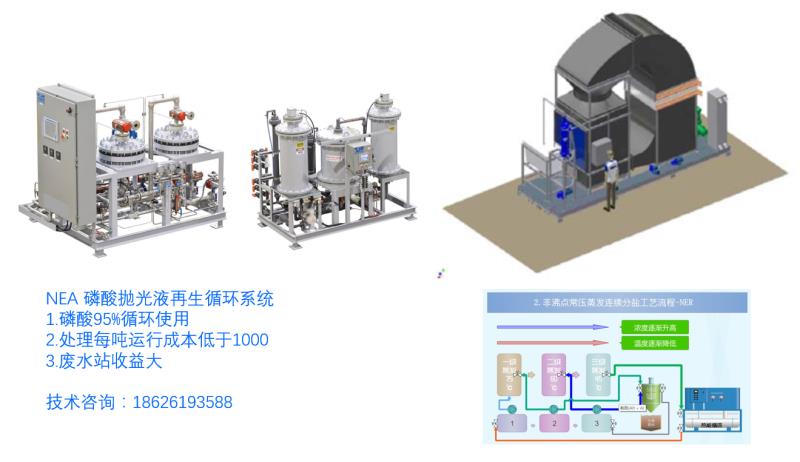

In addition, the used phosphoric acid based polishing solution also contains a large number of unused or "free" acids. The free acid in the spent phosphoric acid polishing solution represents a loss in both valuable chemicals and waste disposal responsibilities. Therefore, the continuous electrochemical polishing / chemical polishing of phosphoric acid based polishing solution can provide the following advantages for aluminum alloy fine decoration manufacturers:

Reduce rework rate and unify product quality

Increase the average pickling speed

Reduce chemical consumption

Reduce waste treatment requirements

2. Treatment process of waste phosphoric acid polishing solution

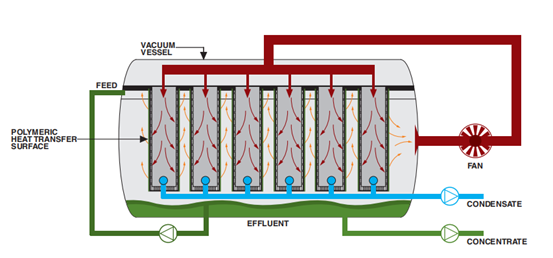

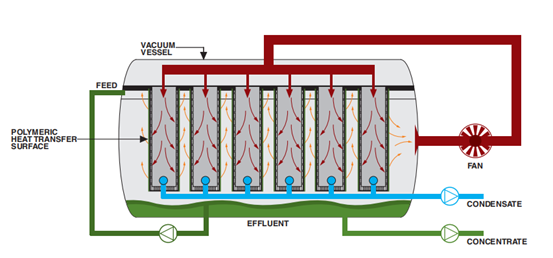

Fixed short bed technology + special separation membrane technology (special fixed short bed technology with the ability to adsorb strong acids and eliminate the surface treatment salt of aluminum alloy of these acids). And the acid can be easily washed out of the fixed short bed technology particles with water. Although this phenomenon, known as "acid hysteresis", has been found by researchers in the early 1960s, it was not successfully commercialized at that time, which may be due to the limitations of traditional IX device design.

At present, the work of acid retardation is in progress, and a new technology of fixed short bed has been invented by the University of Toronto. This new method, similar to the fixed short bed technology, embodies some unique design features:

fine mesh fixed short bed technology particles - increase surface area per cubic foot, improve reaction kinetics

Low fixed short bed technology bed - reduce pressure drop and equipment size

Fixed fixed short bed technology bed - minimize mixing and dilution of feed and regeneration time

Countercurrent water inflow - to maximize the chemical efficiency of feed and regeneration steps

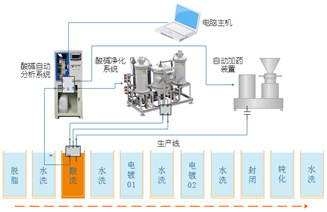

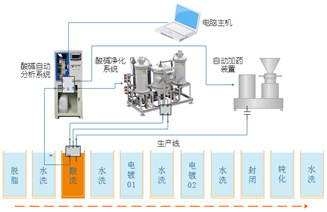

3. Design of phosphoric acid polishing solution treatment system

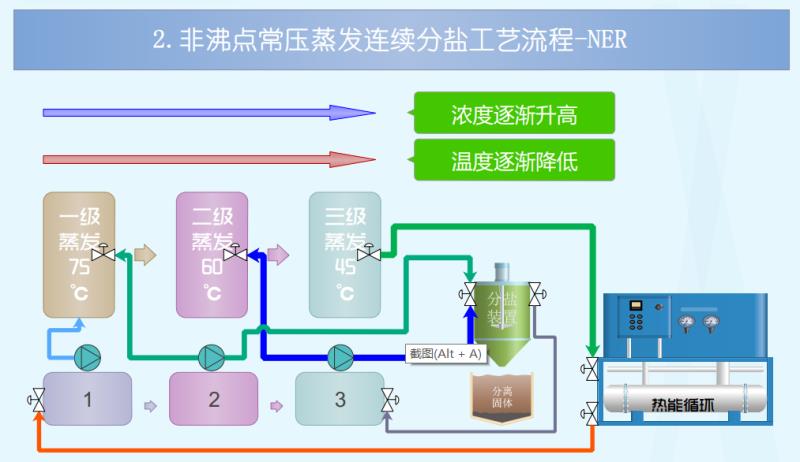

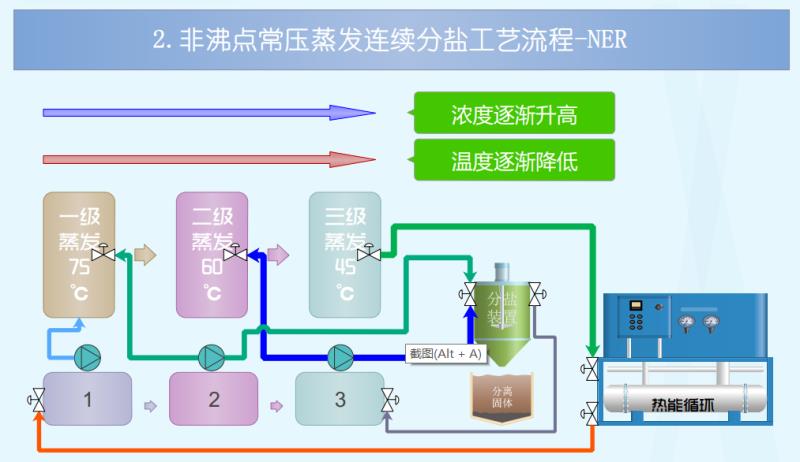

The phosphoric acid polishing liquid to be recovered first enters the filter oil separator, after removing the solid particles, it flows into the phosphoric acid polishing liquid tank by itself, and then it is pumped to the filter to further remove the impurities. The water flows into the buffer tank, and then it is pumped to the composite membrane + fixed bed technology absorption tank, the aluminum alloy surface treatment salt is discharged from the composite membrane + fixed bed technology absorption tank, and then it is sucked by the composite membrane + fixed bed technology absorption tank The attached free acid is then desorbed with pure water in a fixed short bed technology. After low temperature evaporation and concentration, the regenerated acid is reused in the production process