At present, evaporation concentration method is widely used to treat industrial waste liquid. The evaporation concentration method is to vaporize part of the solvent of the solution with the help of external heat source, and then condense it to become a condensate with very low solute content, which can be purified. The nonvolatile solute is retained in the concentrate to obtain concentration. Because the evaporation method has the advantages of high purification coefficient, large concentration multiple and relatively mature theory and technology, it has also been widely studied and applied in waste liquid treatment. Chen Zhiqiang et al. Used low-pressure evaporation method to treat high concentration diosgenin production wastewater. The removal rate of chroma and COD COD was 100% and over 97%, and the effluent could be reused for washing water of production process;

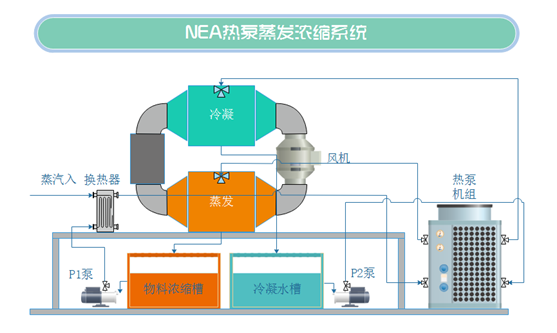

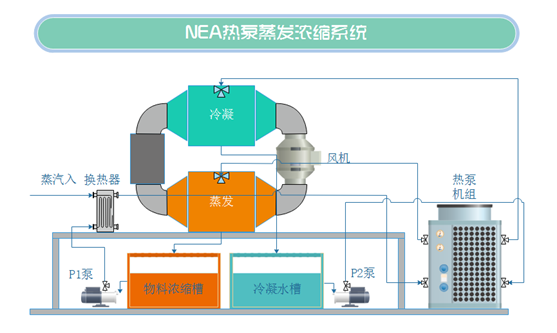

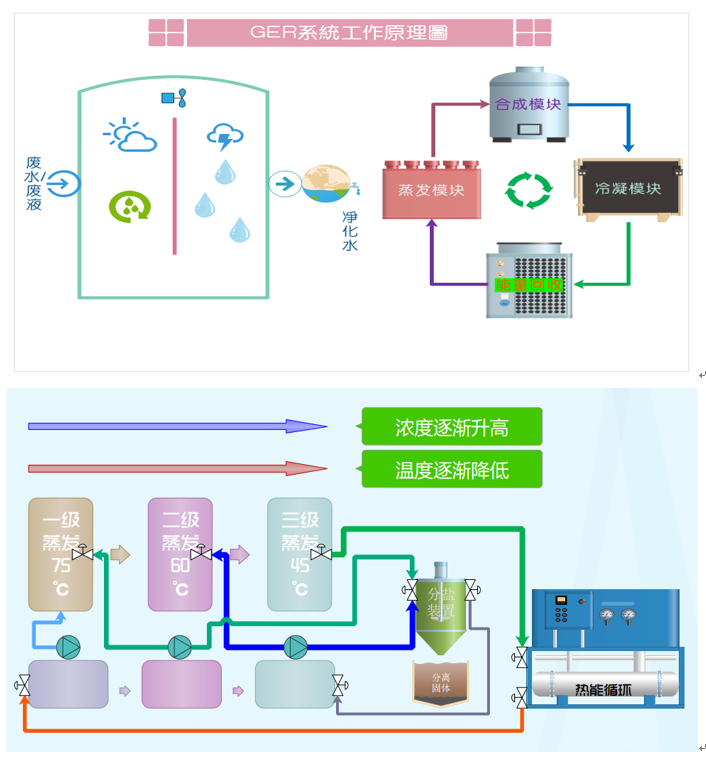

Low temperature evaporation of NEA atmospheric air carrier humidity is a kind of evaporation method compared with high temperature evaporation and boiling evaporation in the scope of atmospheric pressure. This method is suitable for concentration of high boiling point solute and distillation of low boiling point solute. Using the low temperature evaporation method to treat the high boiling point hazardous waste with high moisture content can not only avoid the entrainment or chemical reaction caused by the evaporation of pollutant components in the process of concentration, but also avoid the requirements of high-grade heat source for high-temperature evaporation and concentration, and realize the recycling of low-grade heat source. Therefore, in order to avoid the evaporation of pollutant components and the secondary pollution of ambient air in the process of high boiling point industrial waste liquid concentration, a set of low-temperature evaporation and concentration waste liquid treatment device driven by heat pump is designed. The low-temperature surface evaporation technology is adopted, and the surface water vapor partial pressure of high boiling point waste liquid is different from that of air water vapor partial pressure, so as to realize the concentration and treatment of high boiling point industrial waste liquid Greatly reduce the processing cost.

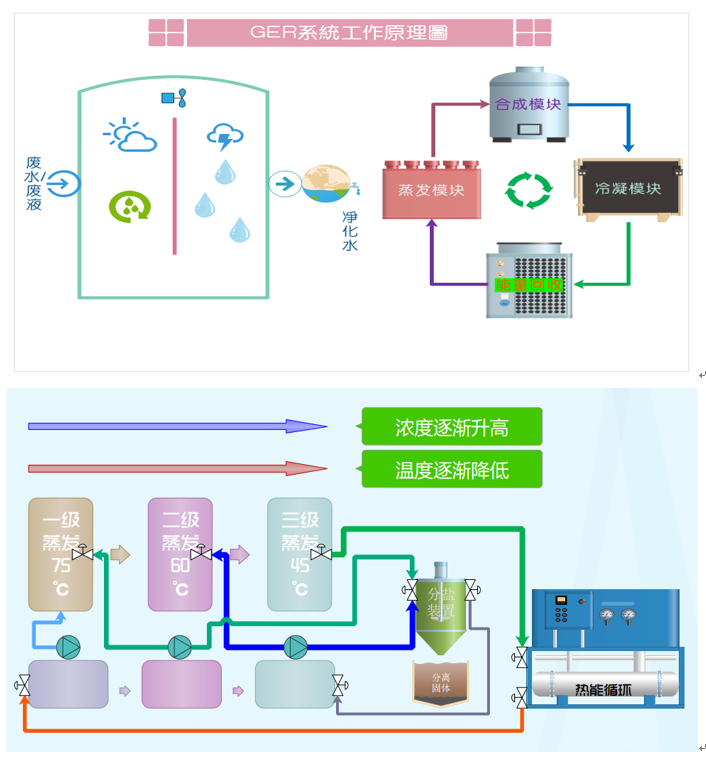

(1) the treatment capacity of the device increases with the increase of spray temperature, circulating air flow and spray flow, and the effect of spray temperature is the most significant. If the spray flow and circulating air flow are too large, the energy consumption of the fan will be increased and the efficiency of the device will be reduced. Therefore, considering the operation efficiency and energy consumption of the device, the spray temperature of 50 ℃ and circulating air flow will be selected

The operation parameters of the device are 0.4658 kg / s and 0.6 kg / s spray flow.

(2) with the increase of treatment time, the treatment capacity of the device first increases, increases to the maximum value, then keeps stable, and then gradually decreases. When the solution concentration is greater than 16%, the treatment capacity decreases rapidly, and the efficiency is sharp

Decline.

(3) the thermal energy efficiency ratio of the heat pump of the device is about 1.7 times of that of the heat pump under the air conditioning condition, and the maximum can reach 7.4.

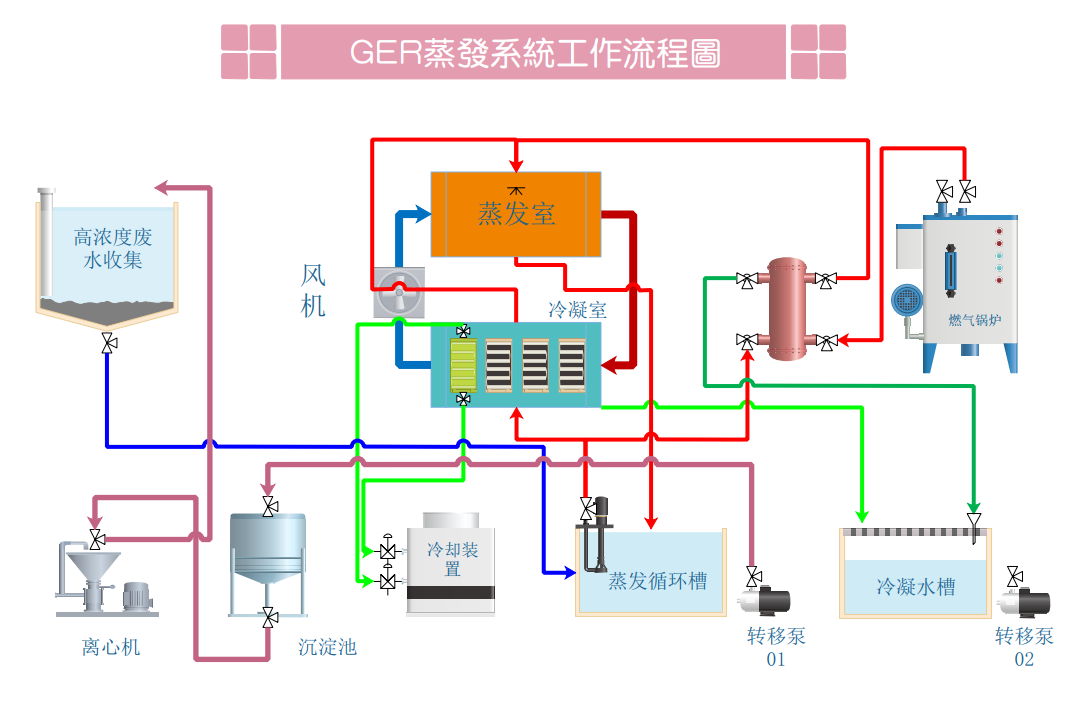

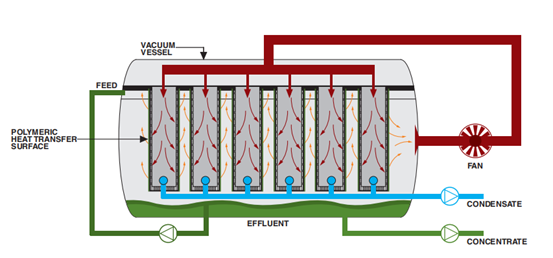

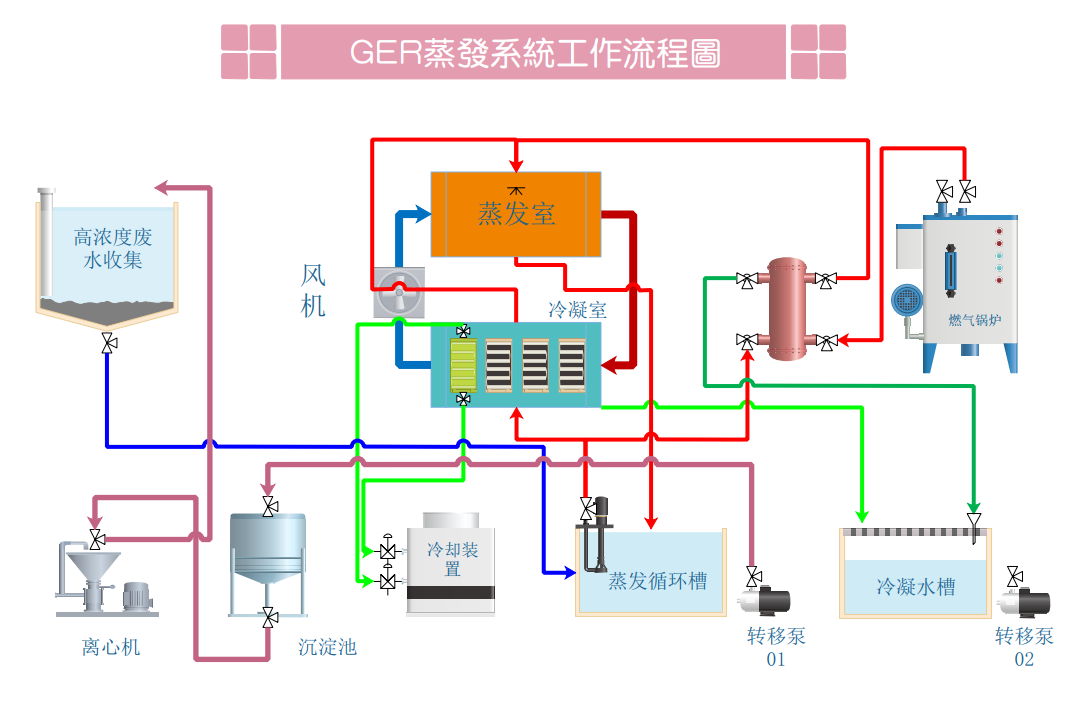

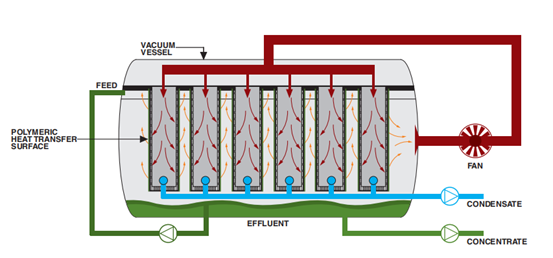

The waste liquid concentration process consists of a storage tank, a circulating pump, a discharge pump, a liquid inlet pump, a plate heat exchanger and a heat and mass exchanger. Driven by the circulating pump, the waste liquid enters the plate heat exchanger for heating to increase the partial pressure of water vapor on the surface of the waste liquid, then enters the heat and mass exchanger for concentration, and enters the storage tank again after the primary concentration treatment. Through multiple circulation treatment, different requirements of concentration treatment are achieved. Finally, the concentrated waste liquid is discharged and collected by the discharge pump. The circulation process of heat pump is mainly composed of compressor, thermal expansion valve, plate heat exchanger, evaporator, auxiliary condenser (radiator), etc. The plate heat exchanger provides heat to heat the waste liquid, and the evaporator provides cooling capacity to condense the moisture in the circulating air. In order to ensure the energy balance of the system, an auxiliary condenser is connected in series behind the condenser to discharge the excess heat of the system. In order to ensure the normal startup of the unit in winter, auxiliary electric heating is set in the solution tank to preheat the waste liquid in the solution tank before starting the heat pump. At the same time, two groups of demister are set in the device. The first group is located behind the heat and mass exchanger and before the evaporator, which is used to remove the entrainment of waste liquid solute in the circulating air, so as to avoid the entrainment remaining on the surface of the evaporator and discharging with the condensed water, affecting the quality of the condensed water. The second group is located behind the evaporator and before the fan, so as to prevent the condensed water from falling into the fan volute and affecting the service life of the fan