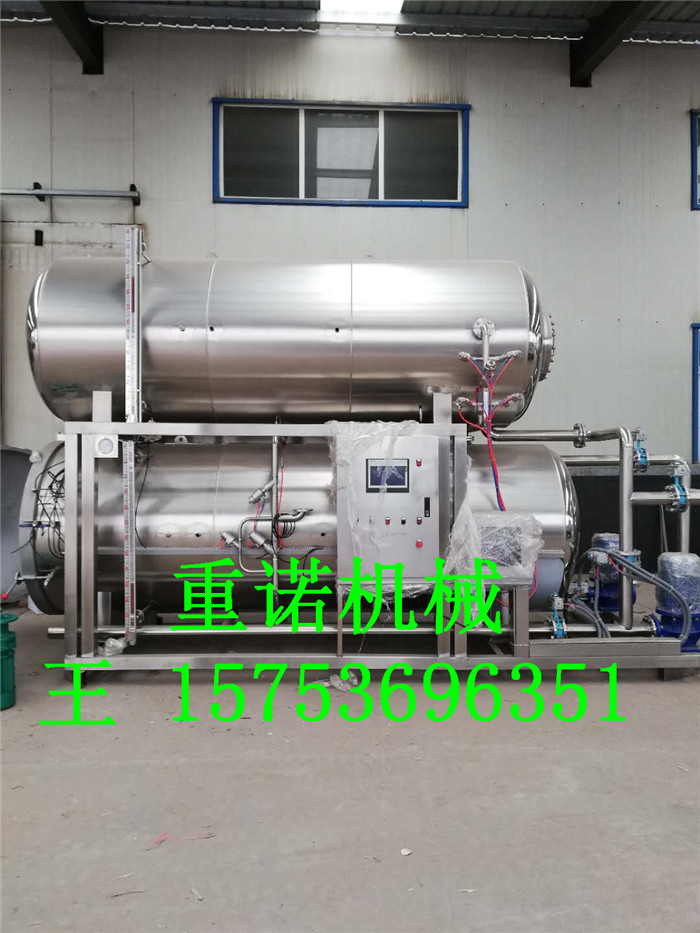

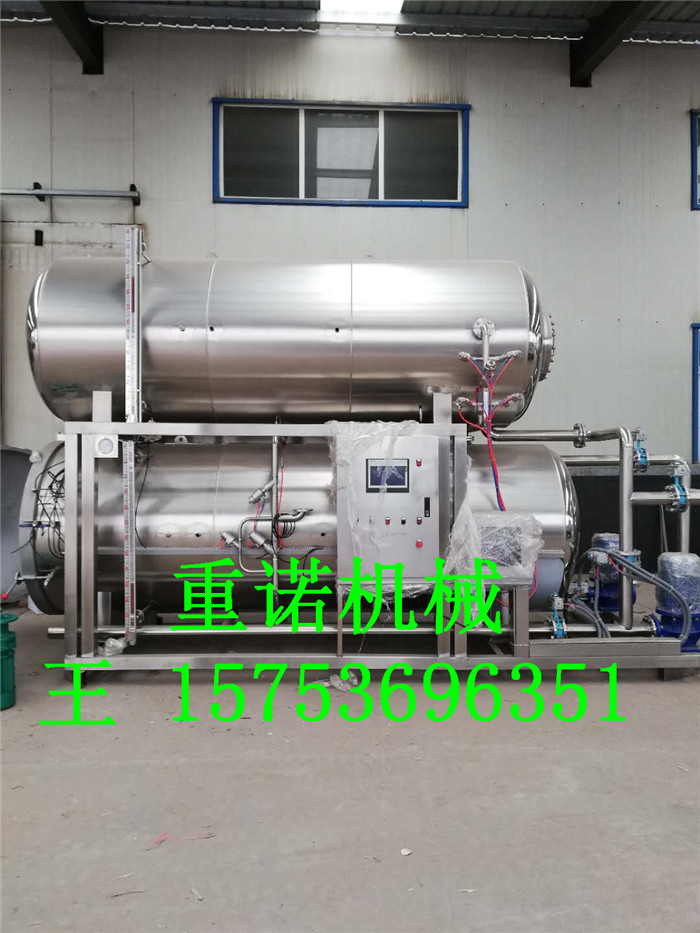

Sausage is a kind of meat food. It is a special meat food in China. It is made by cutting meat into small pieces, mixing with various seasonings and pouring them into casings, drying, fermenting and processing. Sausages are prepared according to individual taste and regional characteristics. Traditional sausage should be finished in a certain period of time or refrigerated. Generally, products packaged in supermarkets or shops are sterilized. When choosing sausages sterilization pot, we should choose water bath sterilization. The sausages produced by sterilization are thoroughly sterilized and have good taste.

There are five control modes, including manual control, electrical control, computer control, computer semi-automatic control and computer full-automatic control (remote control).

1. Manual control folding all valves and pumps are manually controlled, including water addition, temperature rise, heat preservation, temperature drop and other processes.

2. The folding pressure of the automatic control type of the electric appliance is controlled by the electric contact pressure gauge (double gauge, 1 control row, 1 Control Supplement), the temperature is controlled by the sensor (PT100) and the imported temperature controller (the accuracy is ± 1 ℃), and the cooling process is manually operated.

3. The computer-controlled folding adopts PLC and text display to process the collected pressure sensor signal and temperature signal, which can store the sterilization process with high control accuracy, and the temperature control can reach ± 1 ℃. The cooling process (mainly controlling air supply, exhaust, temperature and time) is operated manually.

4. The whole process of computer semi-automatic folding is controlled by PLC and touch screen, which can store sterilization process. The operator only needs to press the start button. After sterilization, the operator will give an alarm automatically, and the temperature control accuracy can reach ± 0.5 ℃. (the whole sterilization process has been digitized and mechanized) basically reached a one touch. (remove the goods in and out and open and close the boiler door)

5. The computer fully automatic control type (remote control type) is folded on the basis of the computer semi-automatic, the whole machine is automatically connected with the front and rear conveyor lines, the whole machine has automatic feeding and discharging, automatic opening and closing of the boiler door, and the guide rail in the boiler can automatically expand and retract forward and backward (the whole machine has achieved digitization and mechanization), which can form the remote control or operation, which is the basis for the unmanned operation appraisal of the workshop. The use of remote control saves time for after-sales service. Mainly from the accuracy of temperature control and uniformity of heat distribution, if the product requires a very strict temperature, especially for export products, because the heat distribution is required to be very uniform, so we should try to choose the computer automatic sterilization pot. The temperature control and pressure control of computer semi-automatic sterilizer are the same as that of computer full-automatic, but the price is 1 / 3 of that of computer full-automatic. Generally, electric semi-automatic sterilization pot can be selected. Manual sterilizer is difficult to sterilize, temperature control and pressure control are all completed manually, food appearance is difficult to master, and the expansion (bag) and crushing rate are high