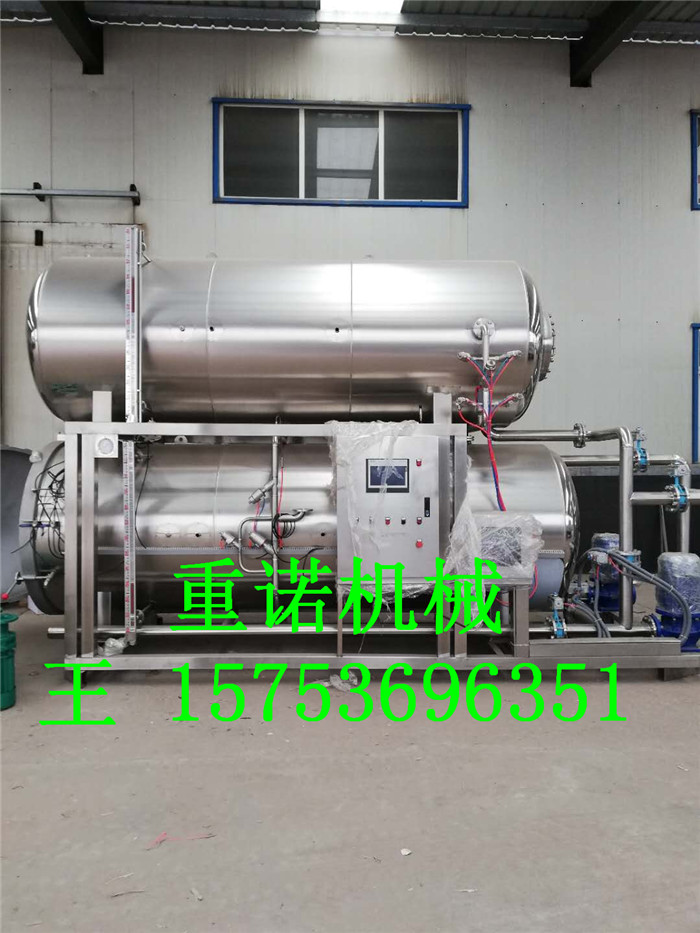

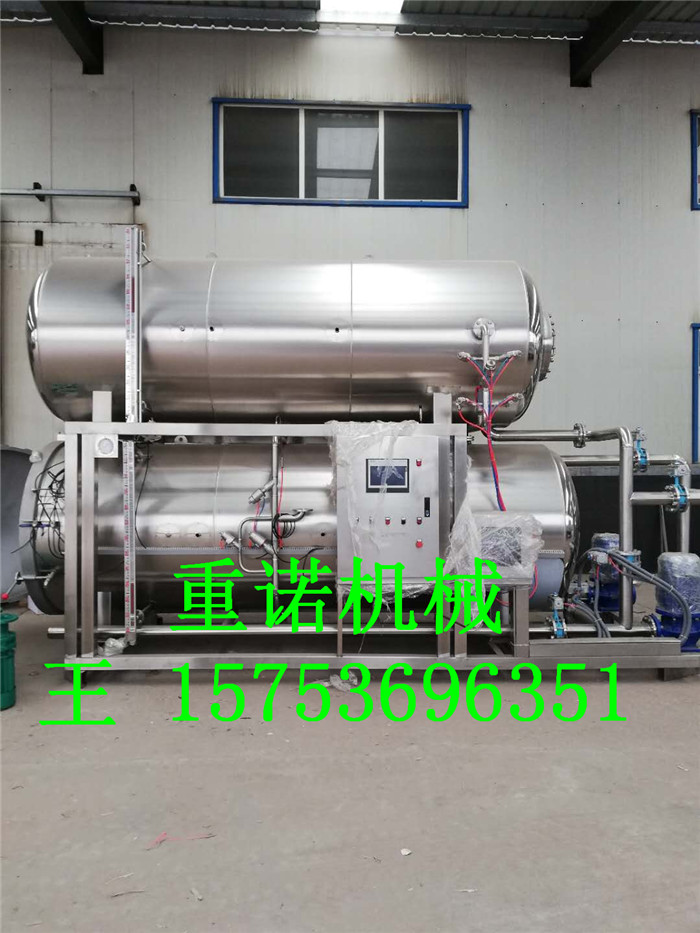

Hot summer, a glass of ice beer to drink, not to mention how cool. Beer is divided into industrial beer and refined beer due to different production processes. The refined beer only uses malt, hops, water and yeast, which is easy to break, so it needs to use sterilization pot. The sterilization of beer needs high-pressure and low-temperature sterilization, which not only can not destroy the original characteristics of beer, but also can guarantee the shelf life of beer. Chongnuo sterilization pot has ten years of production experience, which requires every detail to be better, so that customers can use it safely and safely.

Equipment features:

1. High temperature short time sterilization

In order to shorten the sterilization time and improve the working efficiency, the double tank hot water circulation is used for sterilization, and the water in the hot water tank is heated to the required temperature in advance.

2. Energy saving

The working medium used in the sterilization process can be recycled, which saves energy, time, human and material consumption and reduces production cost.

3、 Uniform water flow exchange mode, uniform temperature, no dead angle

Adopting international advanced technology, using hot water circulation and immersion sterilization, in the process of sterilization, the circulating water in the sterilization tank is continuously switched from top, bottom, left and right, ensuring the uniform heat distribution at any point from heating, heat preservation to cooling in the sterilization tank, effectively eliminating the dead corner phenomenon in the sterilization process, and making the product warranty period more stable and long. The temperature in the sterilization tank keeps stable in all stages of the sterilization process, ensuring the qualified rate of F value.

4. Fully automatic control system

The whole sterilization process is controlled by computer PLC, which can be completed in one time without manual operation. Using chart plate and screen for touch control, all periods are controlled by analog sensors and automatic valves, which can be switched from single sterilization process to multi-stage sterilization process. The pressure and temperature are displayed digitally, and various pressure and temperature modes applicable to any product can be programmed and input into the computer in advance. 100 sterilization formulas can be stored in the computer for easy selection and use