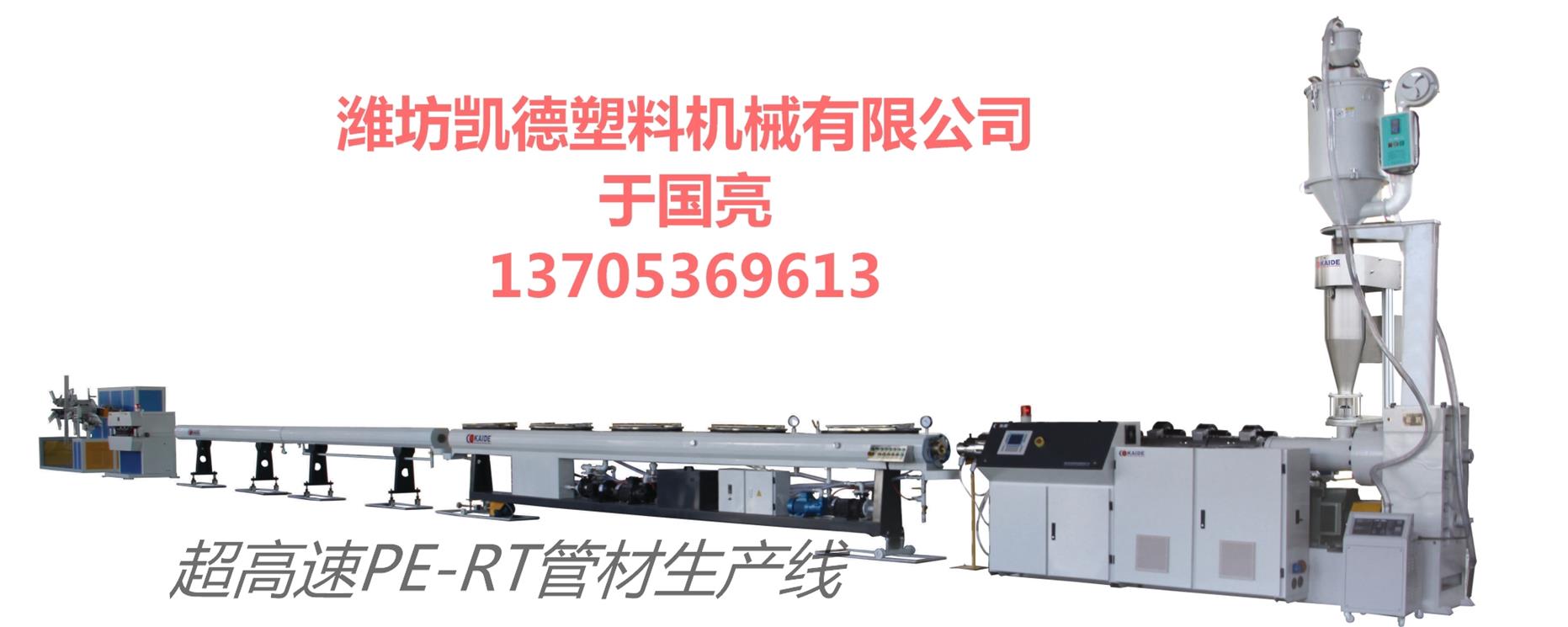

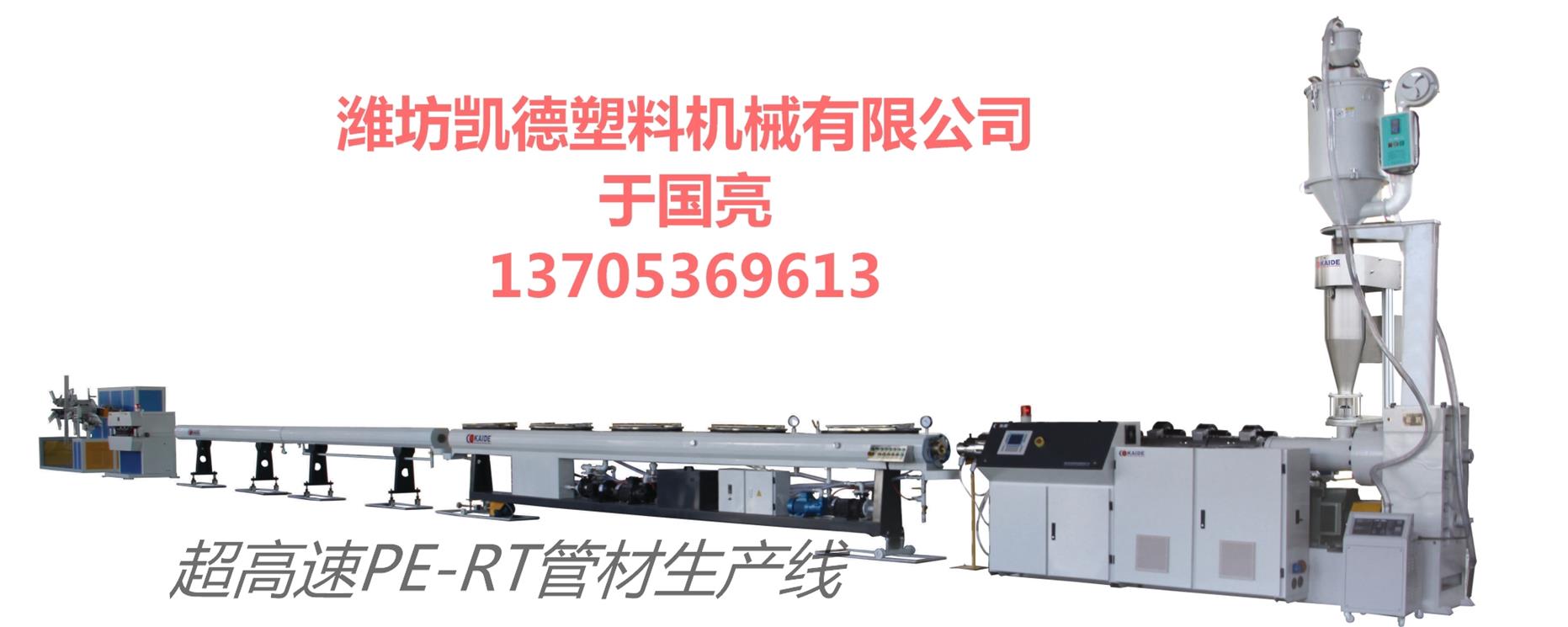

Unit characteristics

More than one thousand technical accumulation high-speed plastic pipe production line - with our company and the composite plastic pipe production line, on the basis of the world first-class equipment, advanced technology, developed by our company independently, the domestic similar equipment production rate is highest, the most reliable performance pilot models;

- imported perfect reliable programmable PCC computer centralized control system, instruction set into production, high speed, convenient operation, stable process;

The precise pipe meters heavy system has been applied in the control unit, to measure the weight and volume calculation of pipe extrusion and meters for its precise control of the system, realize the product m weight constant and according to set parameters, which can shorten the start-up time and improve product quality, saving raw materials;

L adopt imported servo driver of drip feeding, screening, conveying, storage, ration, embedding, forming, punching and continuous action can be completed simultaneously, to ensure the precise position of the dripper adhering firmly;

The structure of extrusion screw, machine head and the sleeve is unique, extrusion plasticizing evenly, pipe surface quality stability;

L using double step type imported servo control traction machine, traction speed can be at any time according to production needs synchronous adjustment, stable and reliable, low noise traction;

The blind hole is equipped with on-line monitoring system - production line, when the system detects that the pipe is not when drilling, will automatically cut off the pipe, and automatically switch the coiling station, and timely report printing waste pipe;

- automatic dual station winding machine, SIEMENS PLC programmable instruction set into independent control; AC servo motor winding pitch adjustable; work with automatic coil pipe, automatic switching off, does not affect the continuous high speed production tubing; equipped with tension control device, control and synchronization of pipe production