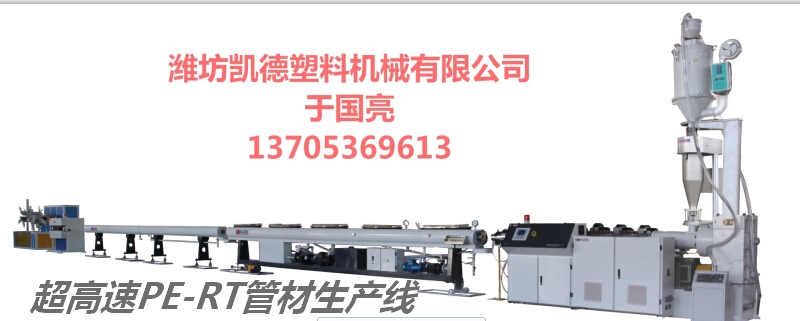

Unit characteristics

A high speed extrusion machine adopts our own design, with completely independent intellectual property rights, the special design of the five part structure for efficient screw and barrel, is to ensure that the material fast dispersing effect and ensure the realization of pipe plasticizing essential elements of high-speed production;

The system is equipped with precise pipe meter to measure the lambda unit, calculation of pipe extrusion amount and meters weight and precise control of the use of the system, realize the product m heavy constant and according to set parameters, which can shorten the start-up time and improve product quality, saving raw materials;

The die unit lambda spiral storage pressure mold the company unique by effectively overcomes the instantaneous fluctuation of extrusion pressure, the pressure of the material in high speed stable extrusion, is to safeguard to realize high speed and stable pipe production;

The successful use of a high speed pipe vacuum sizing device, is to be improved in the design of foundation of our original, has obtained the high speed tube of the invention patent protection sizing device and cooling device to ensure the reasonable structure of the pipe to realize high speed, high efficiency cooling type;

A double automatic coiling machine can realize automatic switching according to the set length of pipe reel, automatic cutting off and automatic coiling; high precision servo drive wiring cable uniform and adjustable pitch, ensuring continuous high speed production tubing; tension control device makes the winding speed and high production speed synchronization; SIEMENS programmable PLC independent control;

The new generation PLC programmable computer control system and multi - point closed - loop control system are adopted to ensure the high - speed synchronous control and smooth operation of the whole production line.

The unit can be configured to add three or five layers of composite EVOH/PE-RT oxygen barrier.