First, the failure to determine the five trick

Look: eye. Look at the local instrument parameters, the appearance of the equipment, accessories, lubricants, etc..

Listen: ear. Listen to the sound of the generator set. Under normal operating conditions, the noise of the unit is continuous, steady and regular.

Touch: hand. To touch the bearing box, the cylinder, the body to determine the vibration, temperature and other conditions.

Nose: nose. Smell, such as leakage, burning of ethylene, propane, oil, paint, etc. there is a big irritant odor.

Than: comparison. A comparison of various states of operation of the unit. Compare, find out the difference, and find out the difference.

From the beginning of the use of machinery and equipment, they also appeared at the same time the equipment fault diagnosis.

With the development of industry and the generations of accumulated experience, summed up the formation of the hearing, touch, smell, see, than the operation of law, which is an artificial realization of a comprehensive fault diagnosis method.

With the improvement of modern testing technology, the accuracy and timeliness of all kinds of advanced testing instruments are more superior. So, this means that the new people do not need to listen to, touch, smell, than, look at these old ways?

Two, the purpose of diagnosis

Both the old and the new, the purpose is the same:

1, equipment status, whether normal

2, abnormal or fault causes and parts in where

3, abnormal degree how, when the repair

4, to determine the extent of the damage caused by the failure, to determine whether the need to immediately stop, whether to maintain the operation, whether the need to reduce the load operation has a decisive role in guiding.

Three, with the times to listen to touch

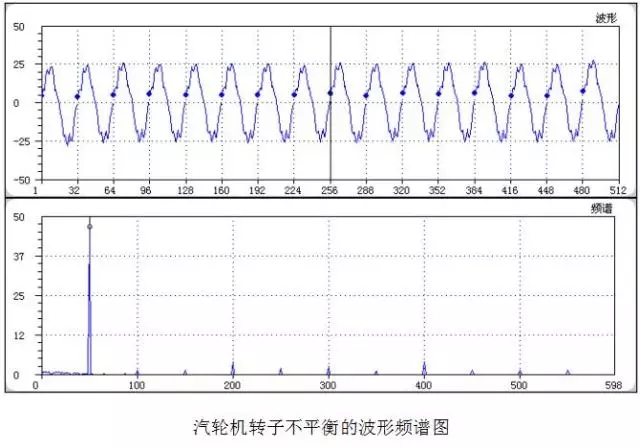

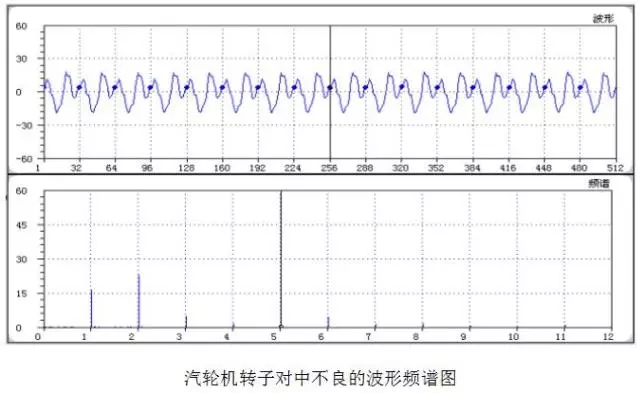

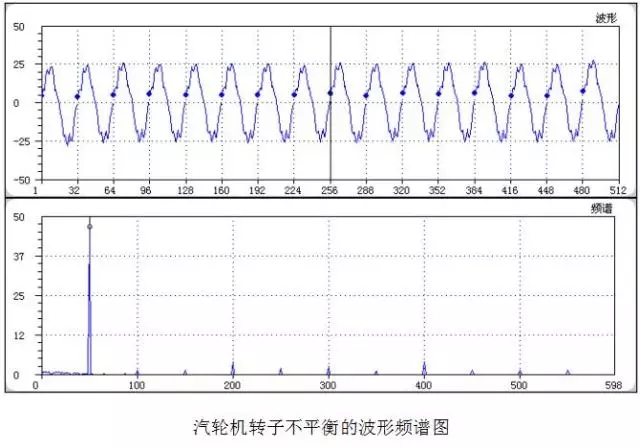

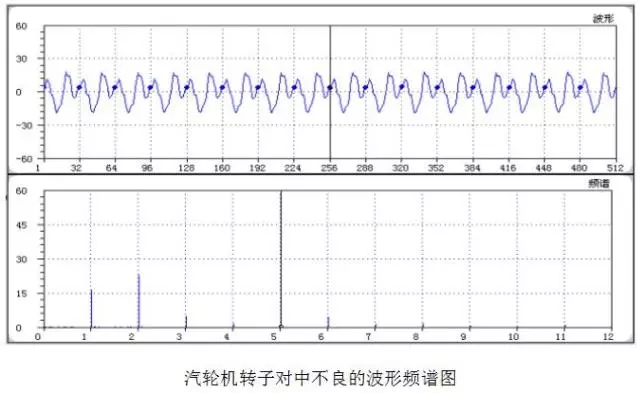

(1) listening to — — vibration

Vibration monitor

As long as the operation of the machine, are more or less vibration, vibration diagnosis in a variety of diagnostic methods in the proportion of the largest, generally up to 60%— 70%.

Domestic vibration monitoring also has 30 years of history, because of the particularity of the domestic equipment unit vibration, and therefore in the vibration monitoring fault diagnosis method, the fault mechanism of the research, has a unique view. After 50 years of practice in the field of fault diagnosis, the unit vibration fault feature has accumulated abundant knowledge and experience, on which many faults and formation mechanism of vibration, are studied deeply and long-term. To correct the traditional misunderstanding.

By using instrumental analysis, the abnormal vibration of the situation can be more convenient to find, but also more accurate.

Noise monitor

The increase of vibration and noise must be caused by fault. In the condition monitoring and fault diagnosis of mechanical equipment, noise monitoring is also one of the most basic methods of monitoring.

By using the noise measurement and identification ability of human ear, the frequency and position of the noise sources are identified by the long-term practice, and the parts and causes of abnormal noise are estimated.

The noise monitor can be used to accurately judge the noise and the noise source.

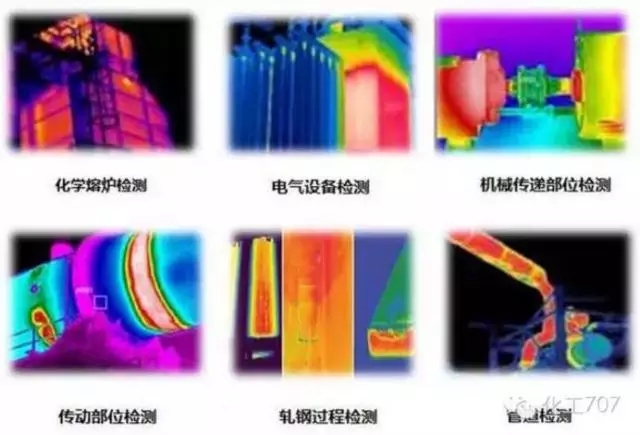

(two) touch — — temperature

Infrared temperature detector

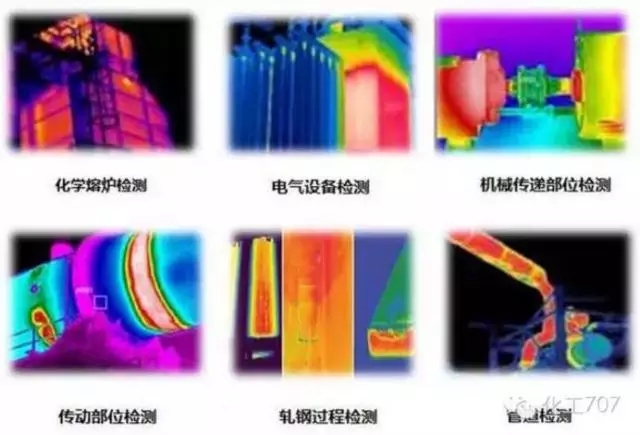

Compared to the original hand to the temperature sensing device, in today's large-scale equipment and system under the circumstances, is clearly not enough professional, so the infrared detector took this job.

Infrared imaging system

Different kinds of objects emit infrared wave band which has its specific band, which is outside the visible light band. So we can use this specific band of infrared light to achieve the object detection and tracking.

(three) look at — — test data

In the large screen system to achieve the results of the noise monitoring display

From the point of view of local instrument parameters, the appearance of the equipment, accessories, oil color, etc. the most intuitive situation, to be able to control the room through various types of monitoring devices to understand the real-time dynamic.

Because of the process system and operation parameters of the situation is sometimes difficult to find out accurately, the instrument is complex and professional problems, three aspects of the investigation to spend more time. In contrast, people to the scene, through the hearing, touch, smell, than, see, often only a few minutes, it can be completed on the overall understanding of the situation. Of course, to do this, you need to rely on the accumulation of experience, usually on the normal operation of the unit experience, experience of the fine, when the failure occurs, the natural will feel the obvious difference. ]

Hearing, touch, smell, than, to see the old experience, coupled with the modern detection equipment, equipment, equipment failure factors will be greatly reduced.

Process equipment network finishing release, reproduced please indicate the source.