[introduction] pipe flange gasket, and the fasteners are collectively referred to as flange joint. Flange joints are widely used in engineering design, which involves a very wide range of parts. It is essential for piping design, pipe valve parts, but also equipment, equipment parts (such as manholes, mirror level gauge etc.) necessary components. In addition, other professional such as industrial furnace, thermal, water supply and drainage, heating ventilation, automatic control, etc., but also often use the flange joint.

GB GB steel flange standards?

GB flange refers to the People's Republic of China national standard "9112~9124-2010 GB/T steel pipe flange," the provisions of the production of flange.

GB flange standard by the State Administration of quality supervision, inspection and Quarantine of People's Republic of China and China National Standardization Management Committee jointly issued by the 2011-01-10, from the 2011-10-01 implementation of the recommended standards.

9112~9124-2010 GB/T includes the following 13 criteria:

In place of the national standard GB/T10745-1989; GB/T9112-2000 standard

Types and parameters of 9112-2010 GB/T steel pipe flanges

9113-2010 GB/T integral steel pipe flanges

9114-2010 GB/T steel pipe flange with neck screw thread

GB/T 9115-2010 welded steel pipe flanges

GB/T 9116-2010 hubbed steel pipe flanges

9117-2010 GB/T with neck socket welding steel pipe flanges

GB/T 9118-2010 welding neck ring loose steel pipe flanges

GB/T 9119-2010 plate welding steel pipe flanges

GB/T 9120-2010 welding ring loose plate steel pipe flanges

GB/T 9121-2010 flat ring loose plate steel pipe flanges

GB/T 9122-2010 flange ring loose plate steel pipe flanges

9123-2010 GB/T steel pipe flange cover

9124-2010 GB/T steel pipe flange

Flange technical conditions?

China's current flange standard is divided into two systems, respectively, PN series (European system) and Class series (American system).

The pressure mark provided by this standard is divided into PN mark and Class mark

PN markers have 12 stress levels, respectively:

PN2.5; PN6; PN10; PN16; PN25; PN40; PN100; PN160; PN250; PN320;; PN400;; PN63;;;;

Class markers have 6 stress levels, respectively:

Class 150; Class 300; Class 600; Class 900; Class1500; Class 2500

Flange material: forged steel, carbon steel, stainless steel, WCB 316L, 316, 304L, 304, 321, Cr Mo steel, chromium molybdenum vanadium, molybdenum, titanium, two fluorine rubber lining material.

A series of GB standards (national standard), JB series (Mechanical), HG series (Ministry of chemical industry), ASME B16.5 (American Standard), BS4504 (British Standard), DIN (German standard), JIS (Japan).

GB flange and non-standard flange of the difference in what?

1, standard flange belongs to the general parts, outer diameter, hole and flange thickness of various specifications are fixed. And the national standard flange to consider the safety factor, so the size and thickness of the safety margin is relatively large.

2, rather than the standard flange is the enterprise or individual in order to save materials, or materials, and their design of flange. General non-standard flange will be designed than the national standard flange smaller, thinner, in order to save material, you can also change the form of sealing surface, such as the O ring seal.

3, the national standard flange on the market can buy, non-standard flange must design their own processing.

4, non-standard flange application is not much, such as a cylinder flange equipment working pressure is 0.3MPA, such as feel no need to use a standard flange 0.6MPA, he designed a small and thin flange, but must consider their own design and manufacture would cost less than you save the material cost.

Flange type and sealing surface form

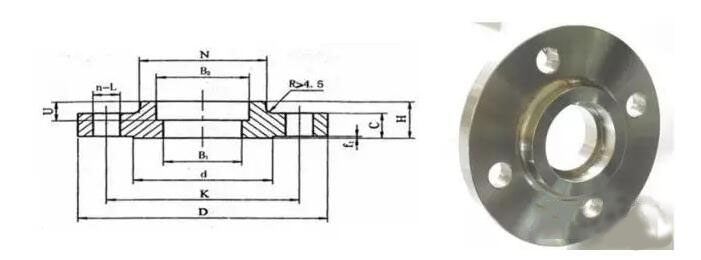

A welding plate flange

Welding plate flange (chemical standard national standard HG20592, GB/T9119, JB/T81: convenient, mechanical) has the advantages of simple manufacture, low cost, wide use; but less rigid, it shall not be used for supply and demand, flammable, Yi Baohe chemical process piping system and height, high vacuum requirements of extremely harmful situations. The main design defects of flange is that it can not guarantee no leakage.

Seal type plane and surface process:

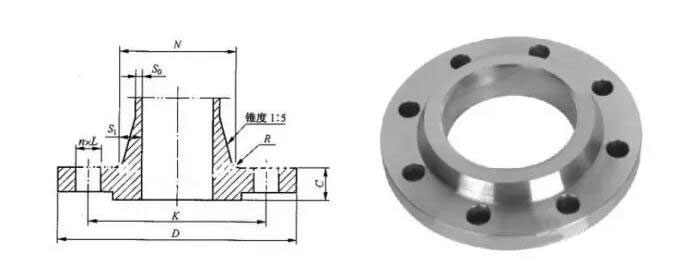

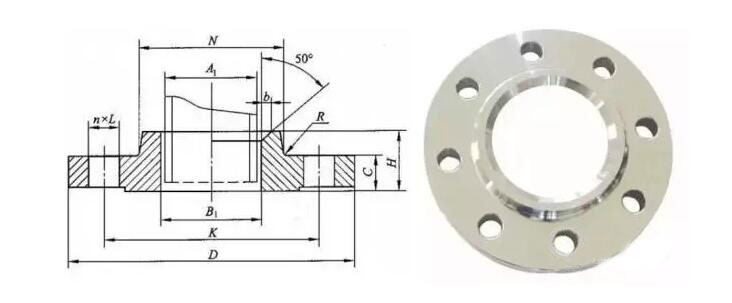

Two, hubbed flange

Hubbed flange flange belongs to the GB standard system, is the standard flange (also known as GB flange) one forms, is one of the commonly used equipment or pipeline flange.

Hubbed flange neck low height, stiffness, bearing capacity of flange is improved. Compared with the welding, welding workload, electrode consumption is not high, high temperature and high pressure and repeated bending and temperature fluctuations, but the site is convenient to install and can be omitted the weld process take rub injury.

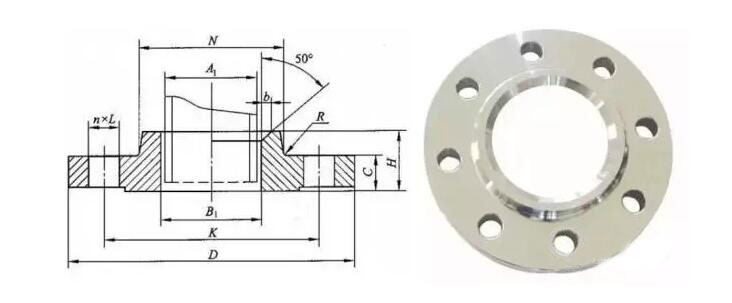

Three, butt welding neck flange

Butt welding neck flange for steel pipe welding neck flange, also called high neck flange, English Name: Slip-on SO.

Hubbed flange with flange plate is the same as the steel pipe and pipe fittings into the flanges are connected by fillet welds and equipment or pipeline flanges.

Hubbed flange sealing surface in the form of:

Process (RF), concave surface(FM), (M), convex tenon surface (T), (G), groove plane (FF).

Hubbed flange diameter range: DN10~DN600

Scope of application: PN2.5~PN40 series Class; PN series Class150~Class1500

Flange material: carbon steel, steel, 304, Luo 316, 304L, 316L, 321, 347, CF8C.

Manufacturing process: forging.

Advantages: hubbed flange also belongs to the flange, because there is a short neck, so as to improve the strength and improve the load bearing strength of flange flange. So it can be used in a higher pressure pipe.

Disadvantages: a welding plate flange cost is higher, because of the characteristics of the shape are more likely to bump in transit.

Four, the overall flange

Is an integral flange connection flange, also belongs to the belt welding neck flange of a steel. Material with carbon steel, stainless steel, alloy steel, etc.. In various standards in the country, using IF to represent the overall flange, and more for the high pressure pipe, the production process is generally cast.

In the flange type is to use a “ IF” to indicate the type of the integral flange. General process surface (RF), if the condition of the use of flammable, explosive, high or extreme harm, can choose the convex and concave surface except RF outside surface (MFM) and groove (TG) of the sealing surface of the form.

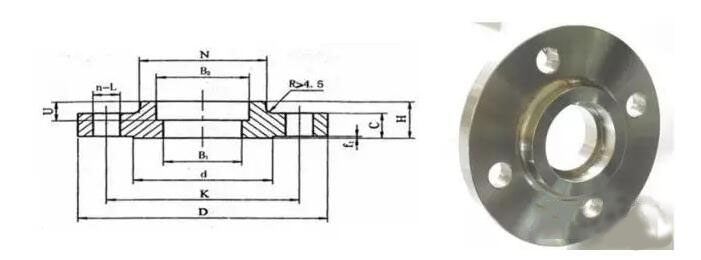

Five, socket welding flange

The socket welding flange is a flange which is connected with one end of the steel pipe to the other end of the pipe.

The sealing surface forms: process surface (RF), convex surface (MFM) and groove (TG) and ring junction (RJ)

Application: boiler pressure vessel, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow food and other industries socket welding flange: commonly used in 10.0MPa; DN&le, PN≤ 40 of the pipeline;

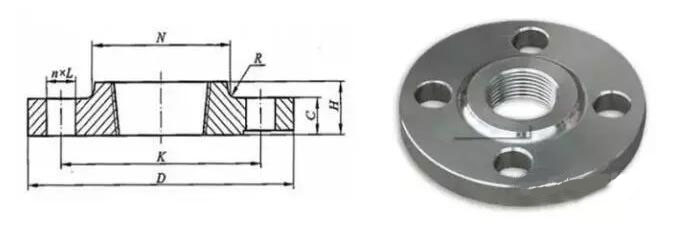

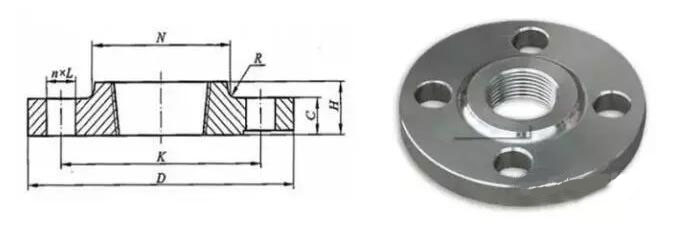

Six, threaded flange

The threaded flange is the inner hole of the flange is processed into the pipe thread, and is connected with the pipe with a thread, and is a non welding flange. Compared with the flange or welded flange, threaded flange has convenient installation and maintenance characteristics, in some field is not allowed to use the pipeline welding.

Alloy steel flange has sufficient strength, but not easy to weld, or poor performance, can also choose a threaded flange. However, the temperature change in the pipe or temperature is higher than the temperature above 260 degrees Celsius below -45 degrees Celsius, it is recommended not to use the threaded flange, so as to avoid leakage.

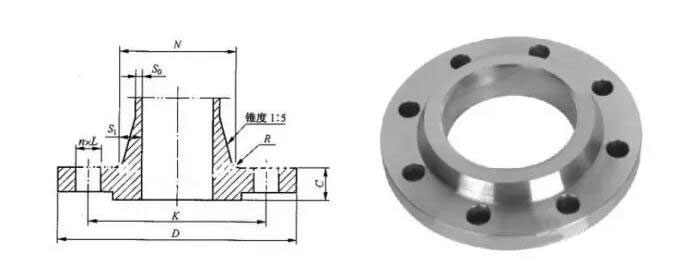

Seven loose flange ring, butt welding

Loose flange ring butt welding flange is movable, generally supporting the drainage fittings factory, expansion joints at both ends have a flange bolt connection pipeline, directly and in engineering equipment.

The use of welding ring loose flange of the general purpose is to save materials, the structure is divided into two parts, one part of the pipe head and the pipe head is made into a welding ring. The flange plate adopts the low grade material, and the pipe part uses the same material as the pipe, so as to achieve the purpose of saving material.

The advantages of the loose flange ring welding:

1, cost savings. When the pipe material is special, the price is expensive, the same material of the welding flange high cost.

2, is not easy to welding or not easy to process or the need of strength. Such as plastic pipes, glass pipes and the like.

3, ease of construction. If the connection is not easy to find the corresponding flange bolt hole flange bolt holes are the replacement of equipment or prevent the day after.

Loose flange ring welding defects:

1, under low pressure.

2, the strength of the welding ring is low (especially when the thickness of 3mm)

Eight, with loose flange ring

Welding-on collar loose flange is a flange can be activities. Directly connected with the pipe and equipment in the project. Use the flat ring loose flange of the general purpose is to save the data, the structure is divided into two parts, a local pipe head and pipe head is made into a flange, the flange part is sheathed on the upper flange. Flange plate using the low level of information, and the use of pipes and pipes as the same as the information, to achieve the purpose of saving information.

The advantages of welding-on collar loose flange:

1, convenient for welding or convenient in the processing or need the strength of large, such as plastic pipe, glass pipe and the like.

2, ease of construction, such as the connection of the flange bolt hole corresponding to the right to find a positive or to prevent the day after the replacement of the flange bolt and bolt, etc..

3, when the price is noble, save cost. When the pipe material is special, the cost of welding the same material is high.

Welding-on collar loose flange defect:

1, accept low pressure.

2, the strength of the welding ring is low (especially when the thickness of 3mm).

Nine, flange cover

Also known as the flange blind flange, blind plate, flange intermediate without holes, for pipe plug seal. With welding head and screw cap is the same, but the blind flange and screw cap can be unloaded, and the welding head.

Sealing surface in the form of many types, with the entire plane, bursting surface, convex surface, groove, ring joint face.

Ten, lining flange cover

The lining flange cover is a kind of blind flange, which is close to the side of the medium, and is welded with stainless steel, which is a whole. The lining flange cover is used for blind plate on the pipeline with corrosive medium. The difference between the common flange cover and the common flange cover is that the anti-corrosion lining layer is added to the contact surface of the medium.

Code marking of flange

1, PN series

Among them, B is the type of flange

C for flange nominal size and application of steel pipe diameter series. If A series can be omitted, B series must be noted in the back. In addition, the integral flange, threaded flange, flange cover of the application of steel pipe diameter series can be omitted.

D for the nominal pressure level PN

E code for sealed form

F for steel pipe wall thickness, provided by the user. Hubbed welding flange, butt welding ring (loose flange)Steel pipe wall thickness

G for material grades

H said the other, such as additional requirements

2, CLASS series

Among them, B is the type of flange

Nominal size of flange for C

D for the nominal pressure level Class

E code for sealed form

F for steel pipe wall thickness, provided by the user. Hubbed welding flange, butt welding ring (loose flange) should indicate the thickness of steel tube

G for material grades

H said the other, such as additional requirements

Process equipment network finishing release, reproduced please indicate the source