[introduction] heat exchanger is widely used in the fields of metallurgy, chemical industry etc.. The application of heat transfer technology of heat exchanger can save energy and environmental protection, reduce operating cost.

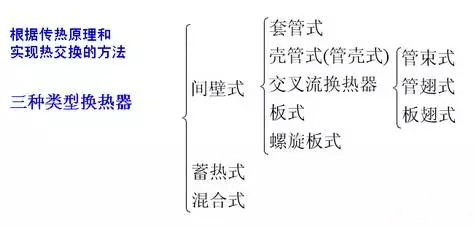

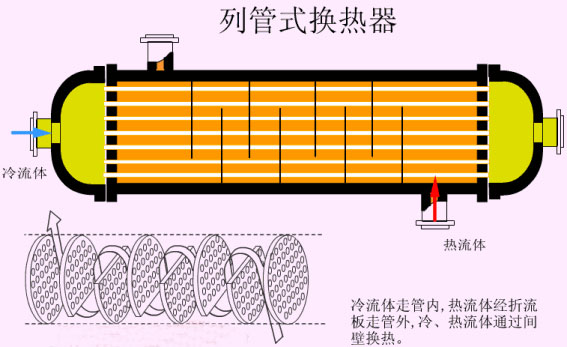

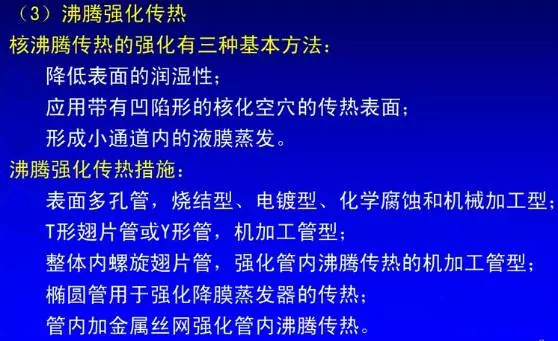

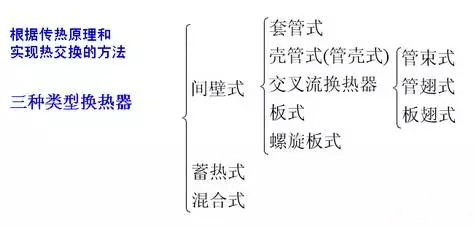

Classification and working principle of heat exchanger

The first three picture for everyone to revisit it working principle of heat exchanger.

Two, strengthen the means of heat transfer

Heat transfer enhancement of heat exchanger is usually used to include three categories: extended heat transfer (F); increase the heat transfer temperature difference; increase the heat transfer coefficient (K).

1, expanding the area of heat transfer F

Extended heat transfer area is the most simple method to increase the heat transfer effect.

Up to now, the purpose of enhancing the heat transfer effect is to increase the heat transfer area of the unit volume.

As in the fin heat exchanger using large heat transfer area per unit volume is relatively large pipe, corrugated pipe, plate fin heat transfer surface and other materials, through the use of these materials, the heat transfer area per unit volume of single equipment will be significantly improved, fully achieve the efficient heat transfer equipment, compact purpose.

2, increase the heat transfer temperature difference T; &Delta

Increase the heat transfer temperature difference T; &Delta is one of the commonly used measures to strengthen the heat exchange effect of the heat exchanger.

In the heat exchanger in the use process, improve the radiation pressure of heating plate tube steam heating, improve the temperature of water with low temperature in deep water instead of tap water condenser cooling water, air cooler to reduce the temperature of the cooling water, can directly increase the heat exchanger heat transfer temperature difference Δ t.

However, increasing the heat transfer temperature difference of heat exchanger T; &Delta has a certain limit, we can not take it as the most important means to enhance the heat transfer effect.

By increasing the heat transfer temperature difference Δ t can improve the effect of heat exchanger; at the same time, increase the heat transfer temperature difference will make the irreversibility of the thermodynamic system increases, reducing the availability of thermodynamic system.

3, enhanced heat transfer coefficient (K)

The most active measure to enhance the heat transfer efficiency of the heat exchanger is to try to increase the heat transfer coefficient (K) of the equipment.

Heat transfer coefficient (K) size is actually composed of the heat transfer process to determine the size of the total thermal resistance, thermal resistance of heat exchanger in the process of the greater heat transfer coefficient of heat exchanger (K) value is lower; heat transfer coefficient (K) value is low, heat exchanger the effect is worse.

In the process of using, the total thermal resistance of the heat exchanger is the superposition of the thermal resistance, so to change the heat transfer coefficient, we must analyze the thermal resistance of the heat transfer process.

From the above formula, we can know: to improve the heat transfer coefficient, we must try to improve the α 1 and α 2 and λ to reduce the δ and the internal and external fouling resistance R1 and R2.

Three, enhanced heat transfer technology

Enhanced heat transfer technology is divided into passive and active reinforcement technology. The former refers to the technology that does not need to consume additional power in addition to the transmission power of the medium. The latter is a technique that requires additional power to achieve the purpose of heat transfer enhancement.

1, passive heat transfer enhancement technology

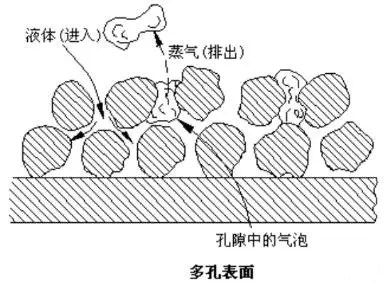

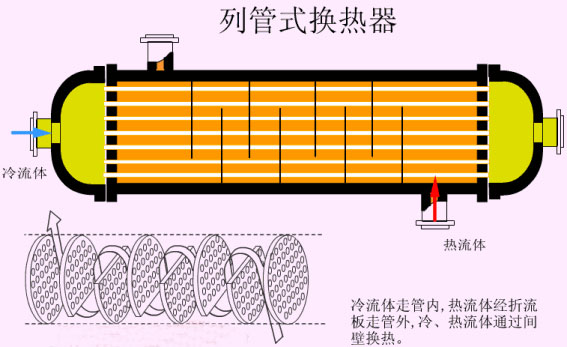

(1) surface treatment

Including small scale changes in the surface roughness and continuous or discontinuous coating on the surface.

The heat transfer surface can be processed into a porous surface or a zigzag surface by sintering, mechanical processing and electrochemical etching, such as slotting, molding, rolling, rolling, rolling, hydrophobic coating and porous coating.

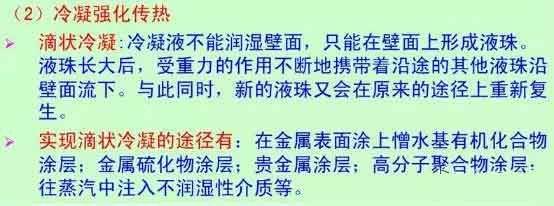

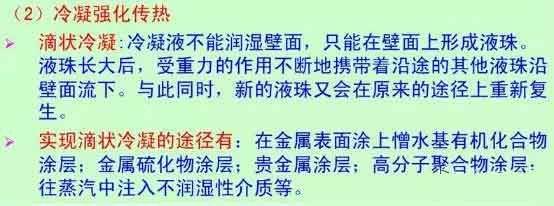

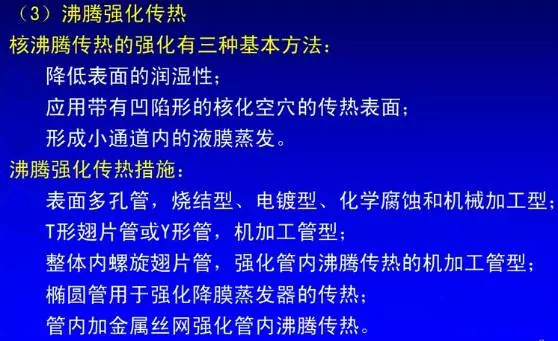

The roughness of the treated surface can not reach the height of the single phase fluid heat transfer, which is usually used to enhance the boiling heat transfer and condensation heat transfer.

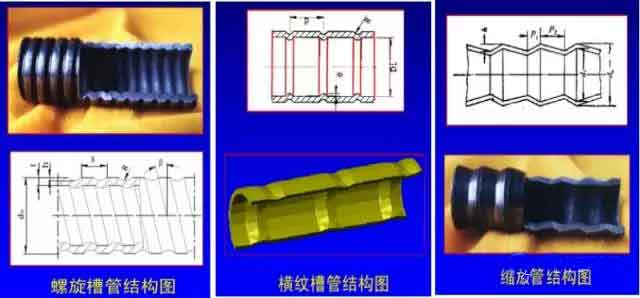

(2) rough surface

Rough surfaces can be produced by machining, milling, and electrochemical etching.

The rough surface is mainly to reduce the thermal resistance by promoting the turbulence intensity, the barrier boundary layer near wall region of the continuous development of Fluid Laminar sublayer thickness decrease, rather than increase the heat transfer area to achieve the purpose of heat transfer enhancement, is mainly used for heat transfer enhancement of single-phase fluid, strengthening effect on boiling and condensation process.

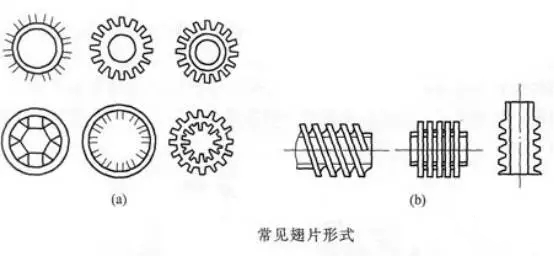

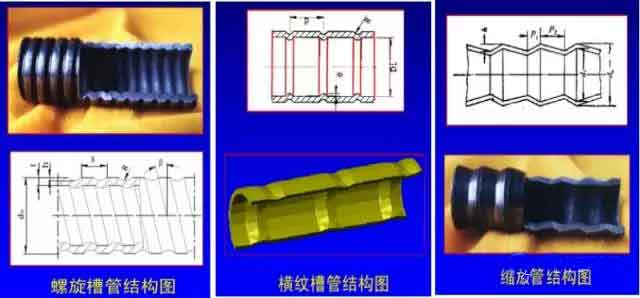

The rough surface technology developed a variety of special-shaped tube strengthen the application in industrial production is quite extensive, including: strengthening based on twisted tube, the boiling heat transfer tube and spiral boiling heat transfer of the spiral tube, the cyclone tube, zoom pipe, corrugated pipe, pin fin tube, horizontal pipe, condensation heat transfer enhancement of serrated fin the petal shaped fin tube, pipe and.

(3) extended surface

The heat transfer enhancement mechanism is mainly such extended surface reshaping the heat transfer surface of the original, not only increases the heat transfer area, and the continuous development of the boundary layer is interrupted, the disturbance degree is improved, which can increase the heat transfer coefficient, heat transfer enhancement of laminar heat transfer and turbulent flow heat have a significant effect.

It is not only used in the improvement of the tube structure of the traditional shell and tube heat exchanger, but also is more and more used in the compact heat exchanger.

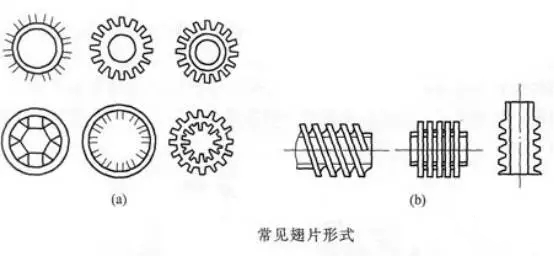

Has developed the extended surface in different types, such as tube fin and tube fin, fork column, short rib wave fin multi hole, pin type, low finned tube, solar rod tubes, louver fin and hole louver fin (in more compact for use in a heat exchanger) etc..

(4) disturbing flow device

The disturbed flow device can be placed in the flow channel to change the fluid flow in the near wall region, thereby indirectly enhancing the energy transfer at the surface of heat transfer, which is mainly used for forced convection.

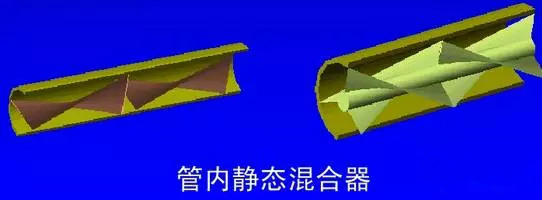

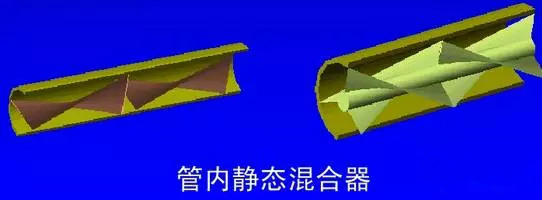

There are many kinds of interference flow devices, such as metal grid, static mixer and all kinds of ring, disc or ball.

(5) vortex flow device

Includes a lot of different geometric arrangements or tube inserts, such as the built-in vortex generator, the link insert and the axial core insert with a spiral coil.

Such devices can increase the length of the flow channel and generate a rotational flow or (and) two flow, which can enhance the radial mixing of the fluid and promote the velocity distribution of the fluid.And the uniformity of temperature distribution, and the heat transfer can be enhanced.

Mainly used to enhance the forced convection heat transfer, the enhancement effect of laminar heat transfer is particularly significant.

(6) spiral coil

Its application can improve the compactness of the heat exchanger, which can improve the heat transfer coefficient of the single phase fluid heat transfer and enhance the boiling heat transfer.

(7) surface tension device

Including the use of a relatively thick core suction material or grooved surface to guide the flow of fluid, mainly used for boiling and condensation heat transfer.

It is commonly used in the case that the cooling medium without core material can not reach the surface of the heated surface, such as heat pipe heat exchanger, and the boiling heat transfer enhancement of the water surface is very effective.

(8) additives

Additive comprising an additive for a liquid system and an additive for a gas system.

The additive liquid comprises a liquid for single-phase flow of solid particles and air bubbles and used for boiling system; including liquid droplets and solid particle additive gas, can be used to dilute phase (gas-solid suspension) or dense phase (bed).

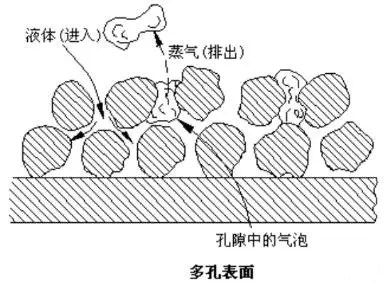

(9) shell strengthening

One is to change the shape of the tube or the tube with fins, which is to enhance heat transfer by means of the shape of the tube or the surface properties.

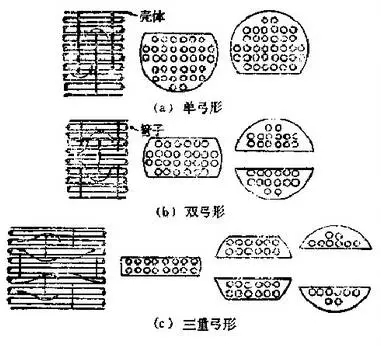

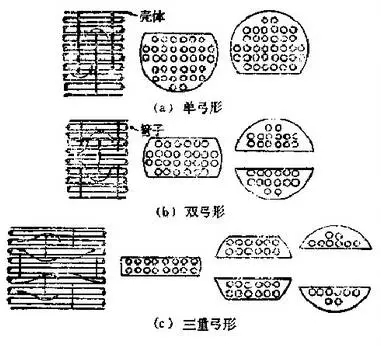

Two is to change the form of shell side baffle or tube support, as far as possible to eliminate the flow and heat transfer in the shell side of the dead zone, as far as possible to reduce or even eliminate the cross flow components, enhanced or completely changed into a longitudinal flow.

In recent years, many new shell support structures have been developed, which effectively make up the deficiency of the single bow baffle.

Such as double baffle, a three baffle and spiral baffle, baffle, circle window pipes, wave network support, baffle rod, hollow ring type, tube support, twisted tube and mixed tube bundle heat exchanger type etc..

2, active enhanced heat transfer technology

(1) mechanical agitation

Including the use of mechanical stirring method, rotating fluid heat transfer surface and surface scraping. A device with a rotating heat exchanger tube has been used in commercial applications.

Batch processing is widely used in surface scraping viscous fluid in the chemical process industry, such as high viscosity plastic and gas flow, the typical is the scraped surface heat exchanger, widely used in food industry.

(2) surface vibration

Both high frequency and low frequency vibration are mainly used to enhance the heat transfer of single phase fluid. The mechanism is that the vibration enhances the disturbance of the fluid, so that the heat transfer can be enhanced.

The use of fluid induced vibration to enhance heat transfer, depending on the water itself to stimulate the vibration of heat transfer components, will consume little energy.

Using fluid induced vibration to enhance heat transfer can increase the convective heat transfer coefficient and reduce the fouling resistance.

(3) fluid vibration

Because of the high quality of heat exchange equipment, the method of surface vibration is difficult to be applied, and then there is fluid vibration, which is the most practical type of vibration enhancement.

The oscillation generator is used from the diffuser to a piezoelectric transducer, and the range of vibration is about 1Hz from the pulse of the 106Hz to the ultrasonic wave. Enhanced heat transfer for a single phase fluid.

(4) electrostatic field

The electrostatic field can make the fluid near the surface of the heat transfer surface to produce a larger mixing of the main body, so that the heat transfer enhancement.

The electrostatic field can also be used in combination with the magnetic field to form a forced convection. The heat transfer of the single phase fluid in a stationary fluid with the formation of a corona wind energy in a static fluid with sufficient strength.

(5) injection

Including the jet gas through a porous heat transfer surface, or to the upper part of the heat transfer fluid.

(6) suction

The vapor and liquid are removed from the heated surface in a single phase flow through a porous heated surface in a nuclear boiling or film boiling.

It is predicted that the suction can greatly increase the heat transfer coefficient of laminar flow and turbulent flow.

Four, summary

Two or more than two of these heat transfer enhancement techniques can be used in combination to achieve a better enhanced heat transfer effect than the use of a technique, which is referred to as a composite heat transfer enhancement technique.

Process equipment network finishing release, reproduced please indicate the source.