Worked in the factory for many years, but do you really know about pressure vessels? Do you know which devices are pressure vessels? Do you know any of the pressure vessels that are safe to install? What role do they have? Today he took you to understand!

What is a pressure vessel?

A pressure vessel is a closed device that carries a certain amount of pressure. The inside can be gas or liquid.

The regulations on safety supervision of special equipment shall be subject to the following requirements for pressure vessels:

Containing gas (including liquefied gas) container should meet: maximum working pressure (gauge) should be ≥ 0.1 MPa, and the product of pressure and volume should be ≥ 2.5 MPa.L. Liquid containers should be satisfied: the maximum working temperature should be ≥ the standard boiling point.

For gas cylinders, oxygen containing gas, (including liquefied gas) should meet: maximum working pressure (gauge) should be ≥ 0.2 MPa, and the product of pressure and volume should be ≥ 1 MPa.L. Liquid should be satisfied: the standard boiling point ≤ 60 C.

This may be a bit abstract, let's look at the factory, which belongs to the pressure vessel!

What are pressure vessels?

Reaction pressure vessels (code R): used to complete physical, chemical reactions, such as reactor, autoclave, synthetic tower, steam ball, gas generator, etc..

The reaction kettle

Steam ball

Gas generator

Heat exchanger pressure vessel (code E): used for heat exchange of medium, such as tube form waste heat boiler, dryer, solvent preheater, heat exchanger, cooler, etc..

Tube heat exchanger

The following figure for the heat exchanger

The separation of the pressure vessel (code S): used to complete the balance of fluid pressure in the medium buffer and gas separation and purification, such as separator, filter, oil filter, buffer, scrubber, absorption tower, copper washing tower, drying tower, stripper, cylinder, deaerator etc..

The following is the oil gas water three-phase separator

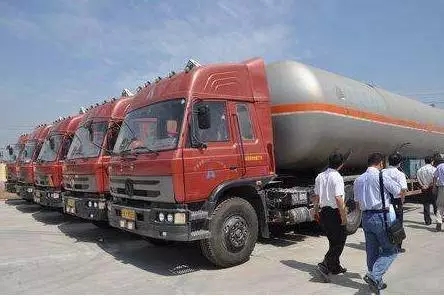

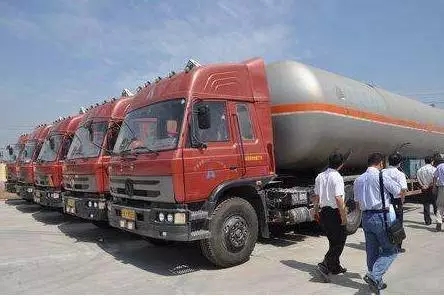

Storage pressure vessel (code C, in which the tank code B): used for storage, storage of gas, liquid, liquefied gas and other media, such as various types of tanks.

Liquefied natural gas storage tank

Propylene Spherical Tank

The above pressure vessel, you can understand? In fact, there are many other pressure vessel classification methods.

Classification of pressure vessels

One

According to pressure

Pressure vessels are divided into internal pressure and external pressure. The internal pressure vessel can be divided into 4 grades according to the design pressure (P).

Low pressure (code L) container 0.1 MPa≤ P < 1.6 MPa;

Medium pressure (code M) container 1.6 MPa≤ P < 10 MPa;

High pressure (code H) container 10 MPa≤ P < 100 MPa;

Ultra high pressure (code U) vessel p≥ 100MPa.

Two

According to position

Pressure vessels can be divided into fixed and mobile.

Fixed pressure vessels, the use of the environment is fixed, can not move. Such as: spherical tanks, horizontal storage tanks, synthetic towers, reactors, dryers, separators, etc..

Mobile pressure vessel is used in the mobile, generally as a kind of medium packaging, mounted on the vehicle. Such as: car and railway tank car tank.

Three

According to the manufacturing method

Welding container, forging container, hot sleeve container, multilayer wrapped container, tape wound type container, combined container.

Four

According to the manufacturing material

Steel container, nonferrous metal container, nonmetal container.

Five

By geometry

Cylindrical container, spherical container, rectangular container, combined container.

Six

By way of installation

Vertical container.

Seven

According to wall thickness

Thin walled vessel.

Basic structure of pressure vessel

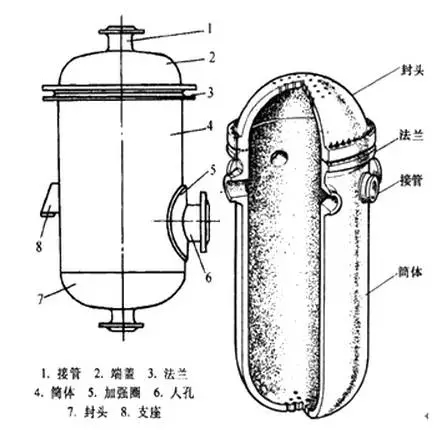

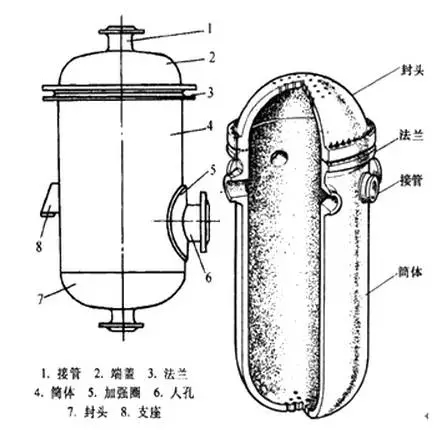

Generally, the pressure vessel is composed of a cylinder body (also called a shell), a head, a flange, a connecting pipe, a manhole, a supporting seat, a sealing element and a safety accessory.

The pressure vessel is a kind of special equipment, the possibility of damage during operation and use of the process is relatively large, the medium temperature and has certain corrosion resistance, and high pressure vessel, long-term use will cause corrosion, deformation cracks, leakage defect.

In the event of an accident is not only the destruction of the container itself, but also lead to a series of vicious accidents, such as the destruction of other equipment and buildings, and even endanger people's lives.

In order to prevent accidents, safety accessories for pressure vessels, it is very necessary.

What are the pressure vessel safety accessories?

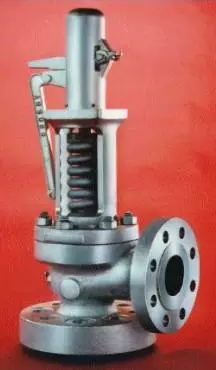

One

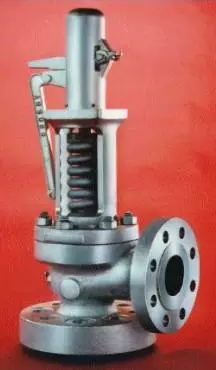

Safety valve

When the pressure inside the equipment exceeds the specified requirements, it can automatically open, release the excess pressure, and make the equipment return to the normal working pressure. After normal pressure, the safety valve automatically closes.

After verification of the safety valve, it is strictly prohibited to add heavy objects, moving the heavy hammer, the valve flap and other means to increase the safety valve pressure settingOr cause the safety valve to fail.

Two

Pressure gauge

The range of the pressure gauge should be in accordance with the working pressure of the equipment, usually 1.5 to 3 times the working pressure, preferably at least 2 times. Pressure gauges should be marked on the red line, the maximum allowable working pressure. Pressure gauge connection pipe should not leak, leakage phenomenon, otherwise it will reduce the pressure gauge indication.

Three

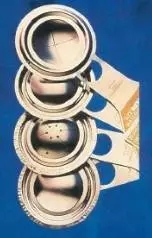

Bursting disc

To be able to blast at a specified temperature and pressure.

Four

Thermometer

The temperature of the liquid medium in the container can be detected.