| Time:2017-08-24 | Source:Process Equipment Network | Pageview:1435 |

The Intelligent Quotation System Make the Project Evaluation in Time and Accurate

As the type of project and non-standard characteristic of process of industria, so equipment quotation needs cooperation from technology, business, personnel management and other professionals, and even by the knowledge, ability and experience of high quality professional team, but the accuracy of project quotation is low, long cycle and low efficiency.

Process equipment network has introduced intelligent quotation system through the accumulation of more than 10 years engineering practice and the simulation of equipment cost ,it solved the following problems of buyers and manufacturers in terms of project valuation:

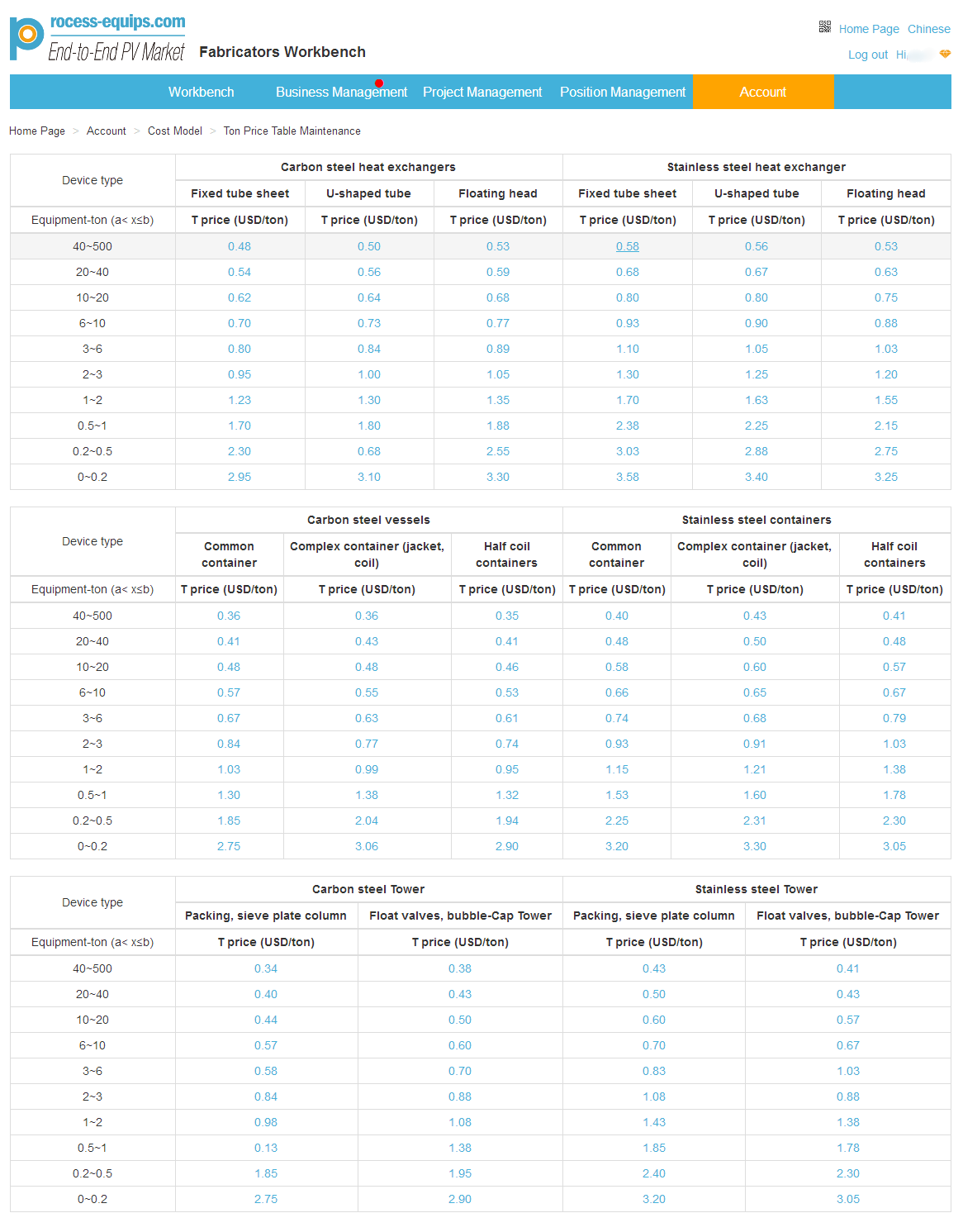

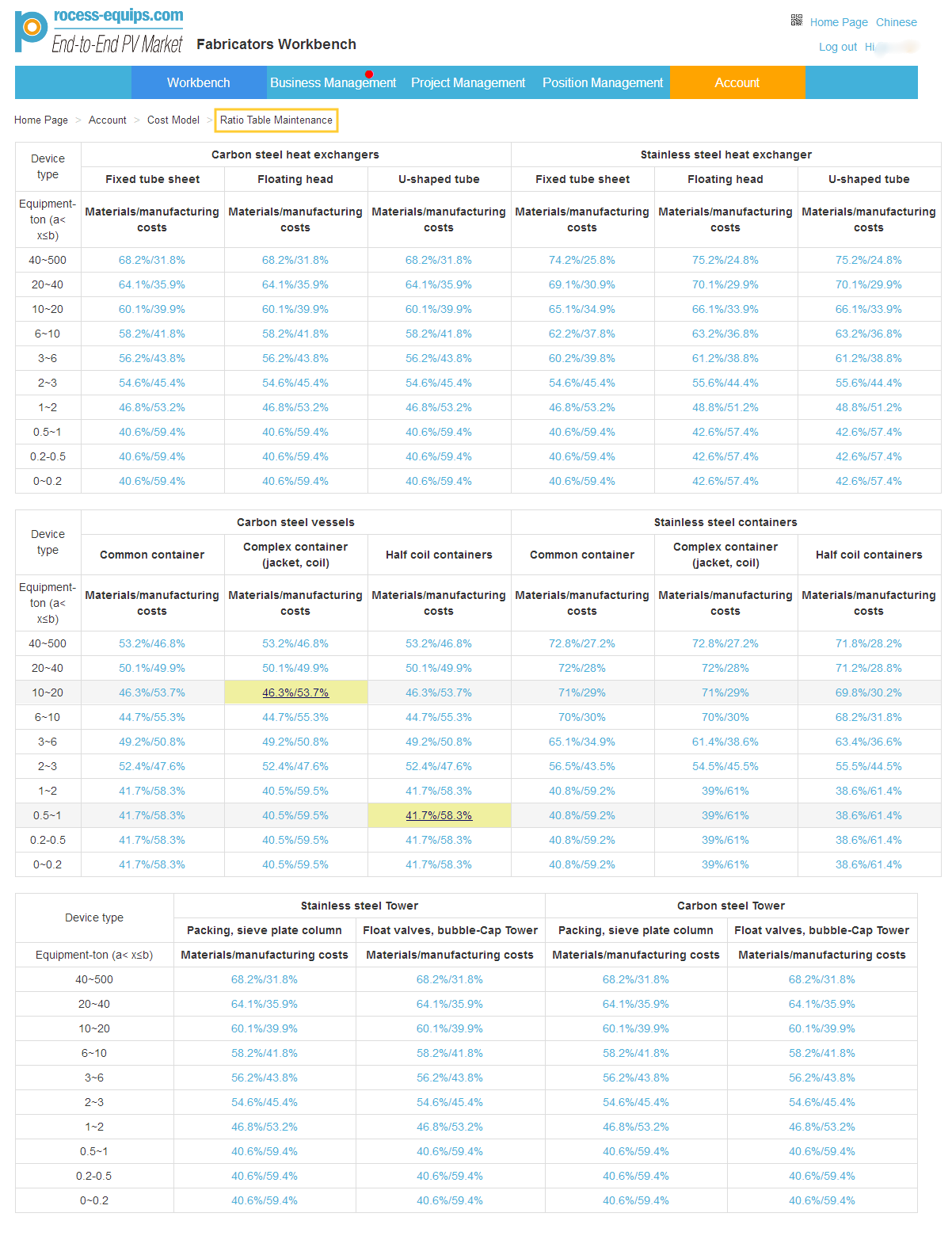

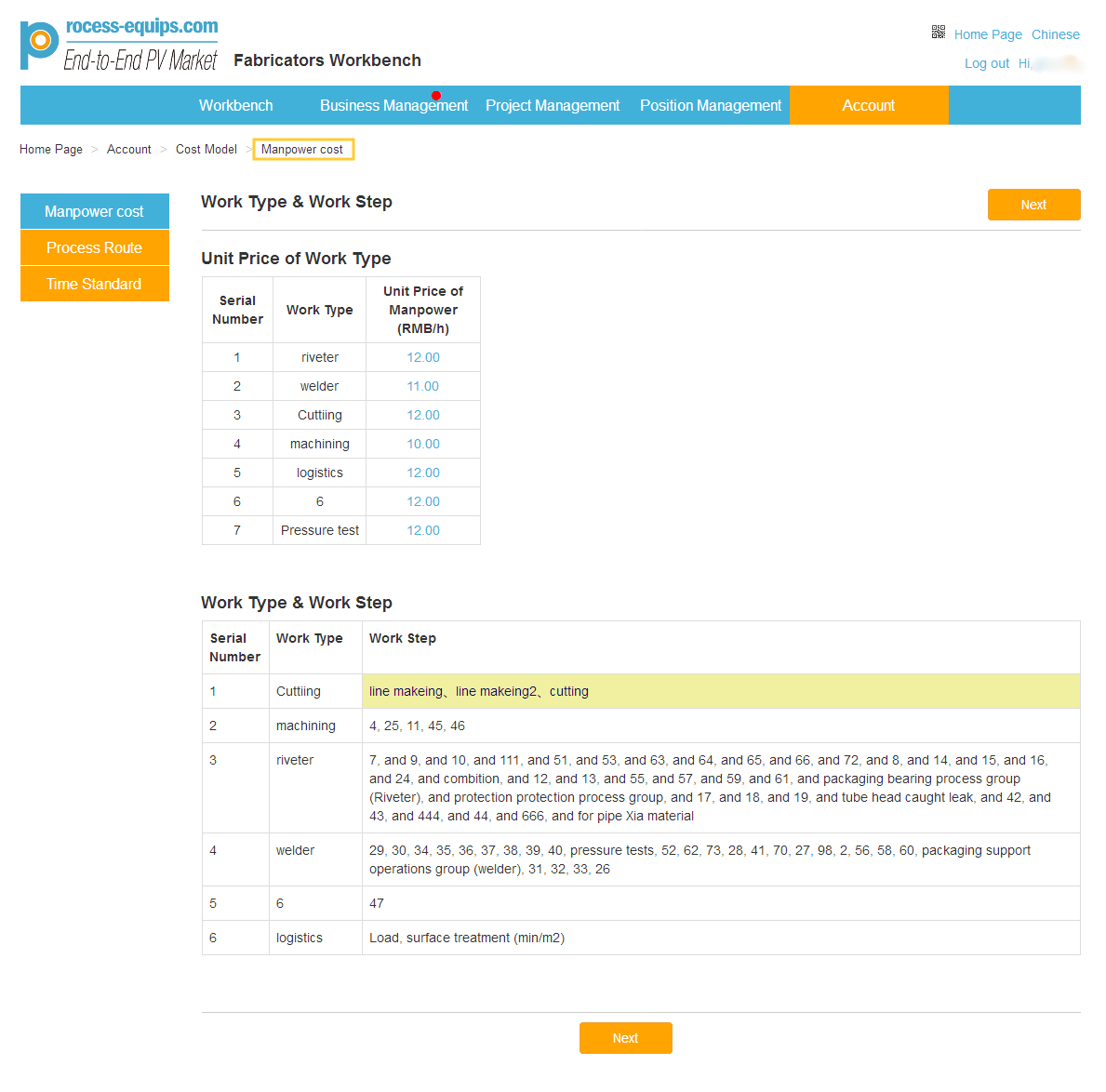

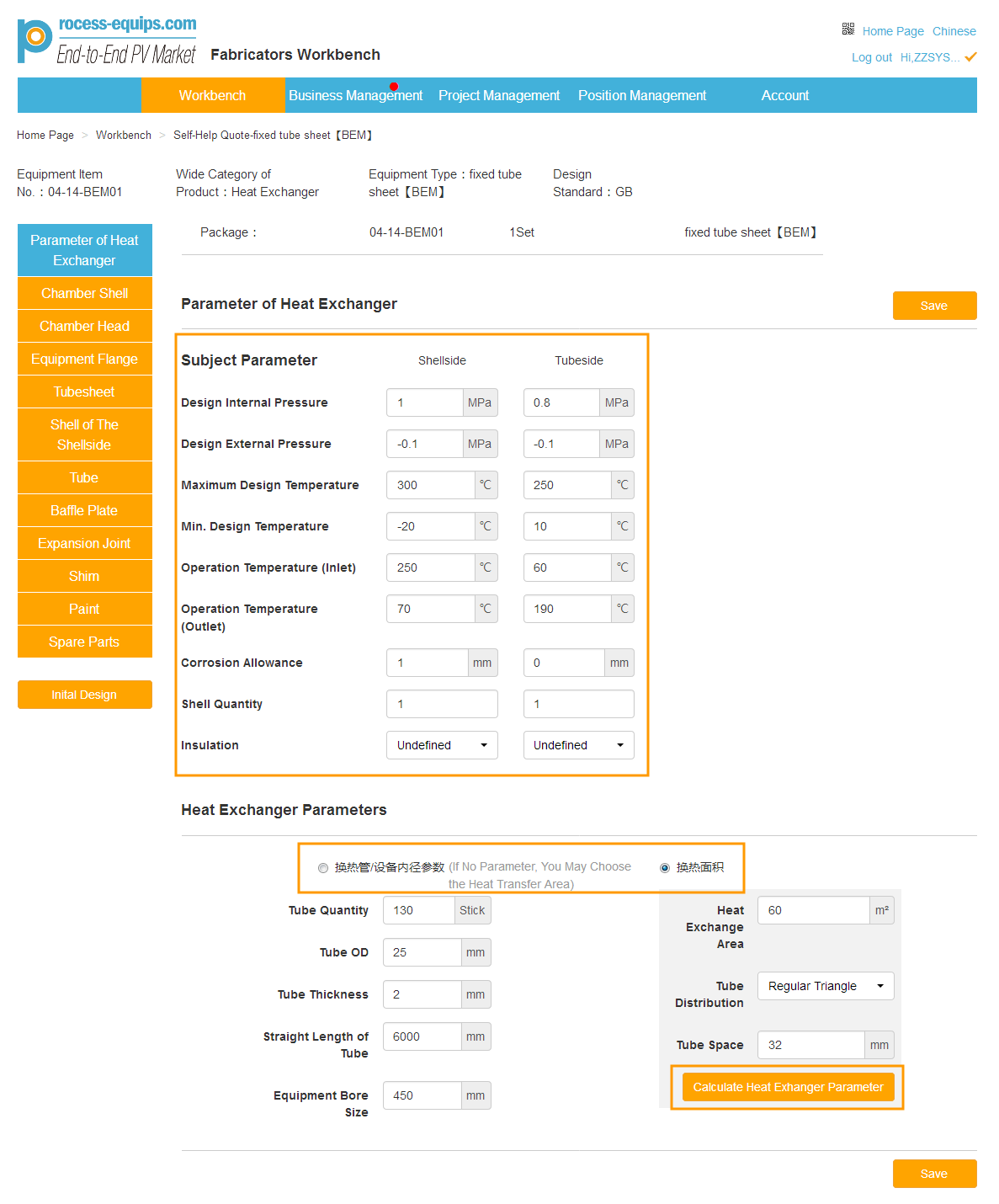

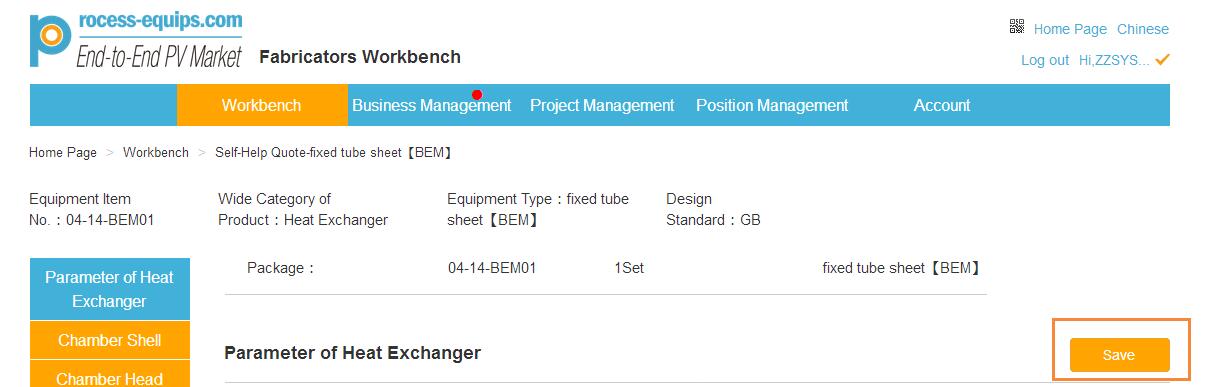

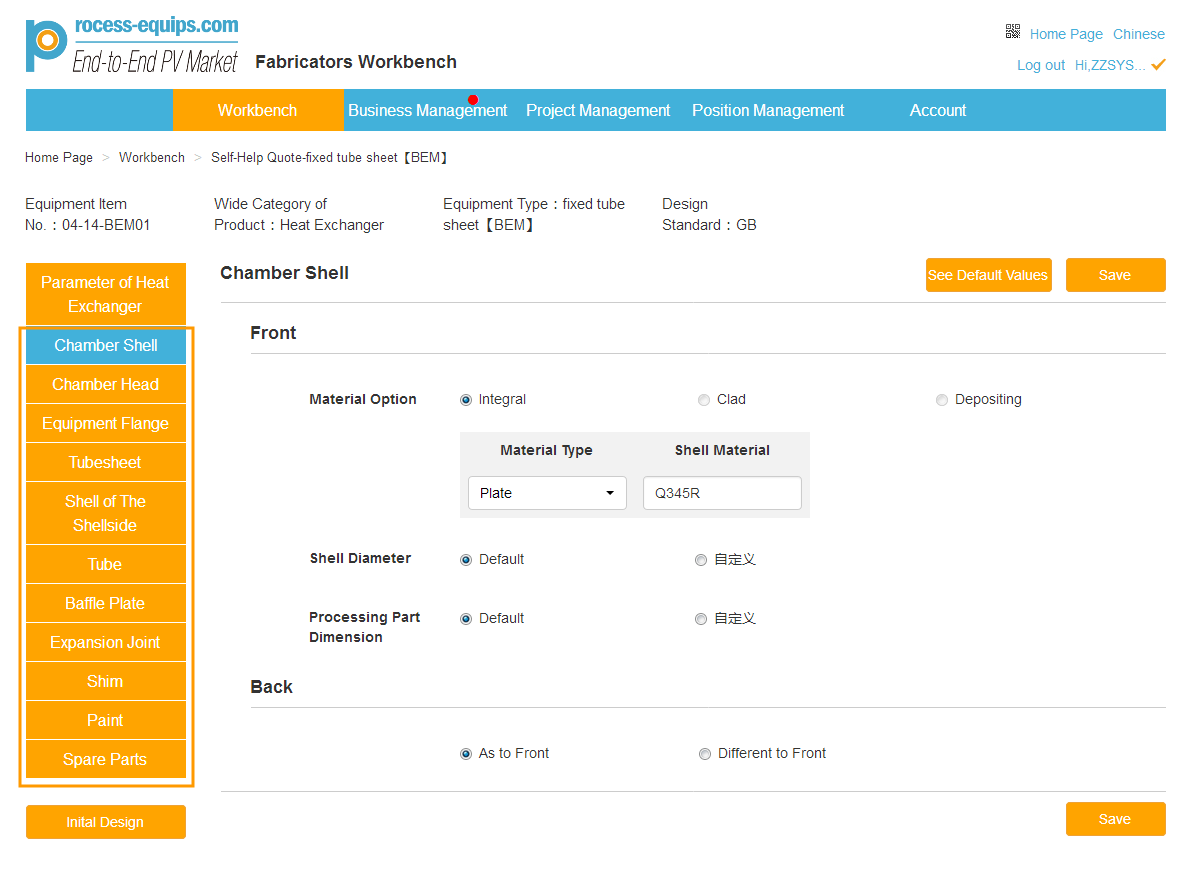

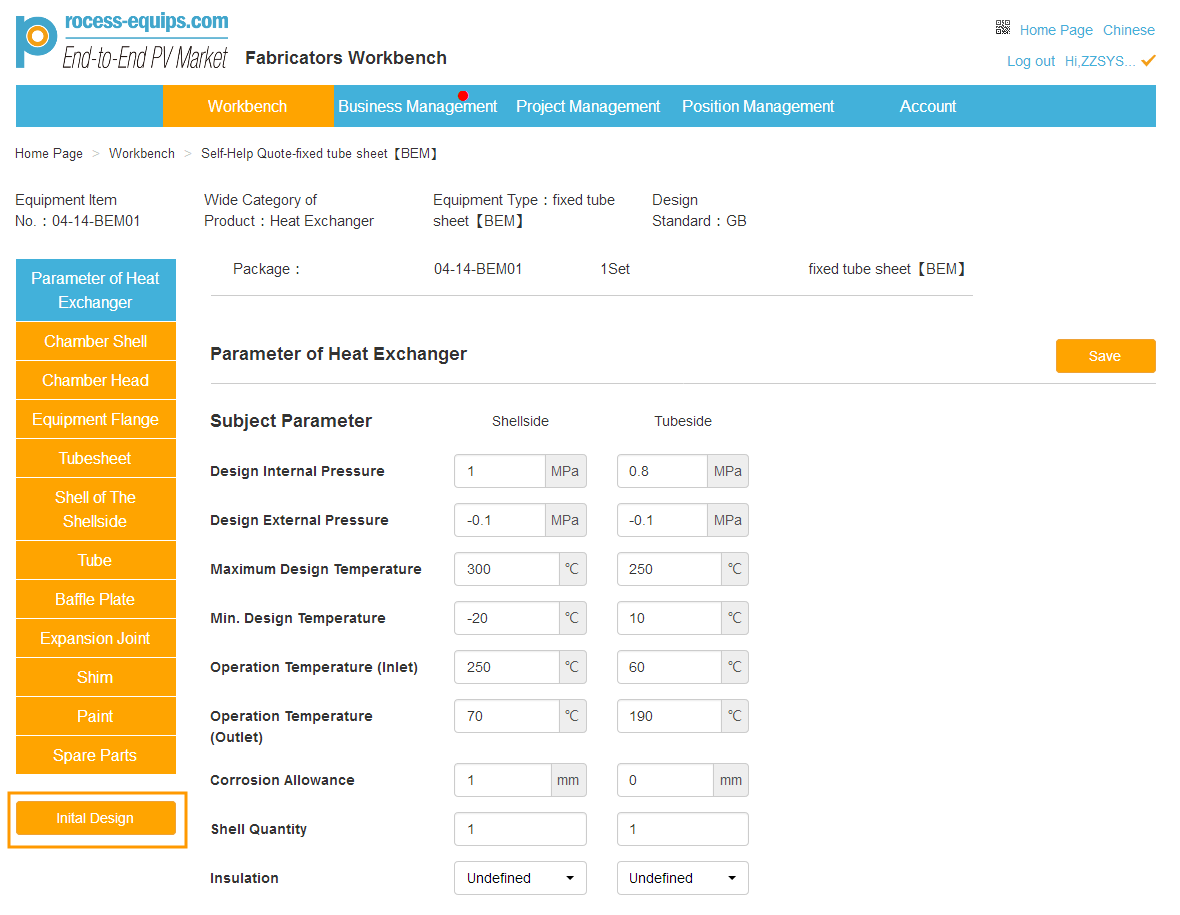

1. Intelligent quotation system has established the equipment preliminary design, selects the newest material price, establishes the manufacturer cost model and so on , greatly reduced difficulty of the process equipment quotation work , causes this work to be more easily and quickly

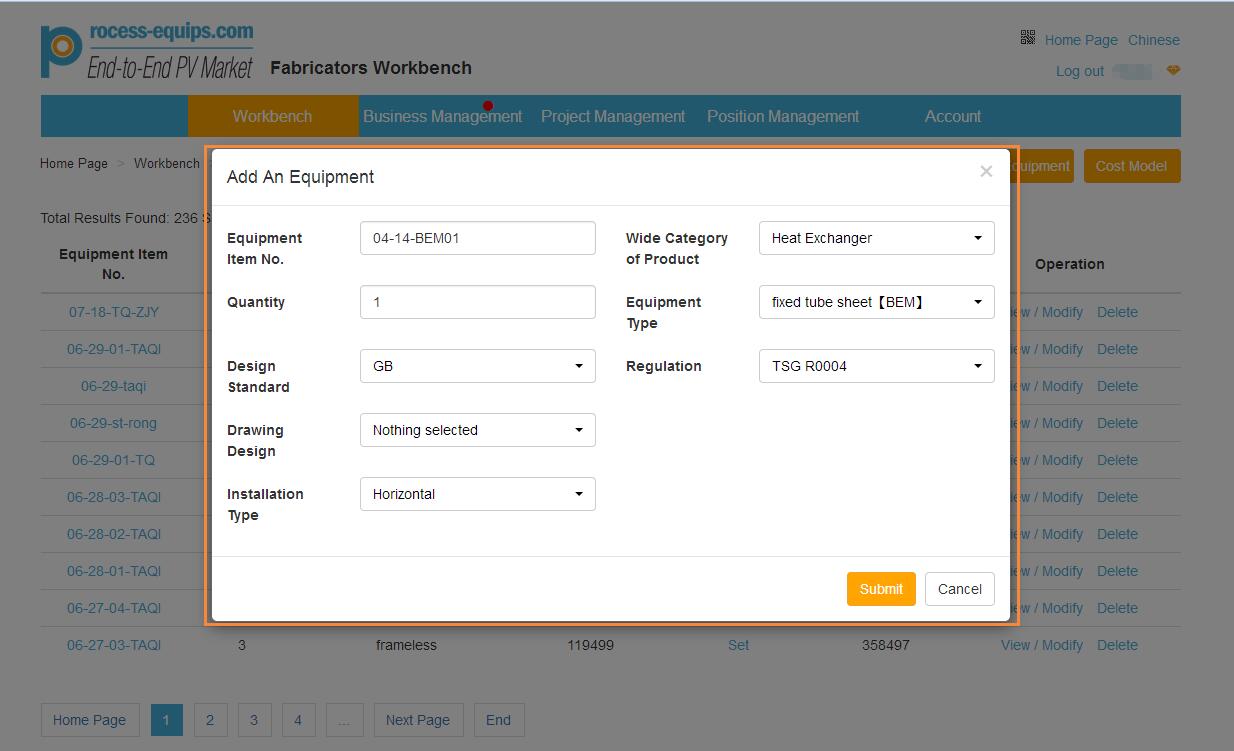

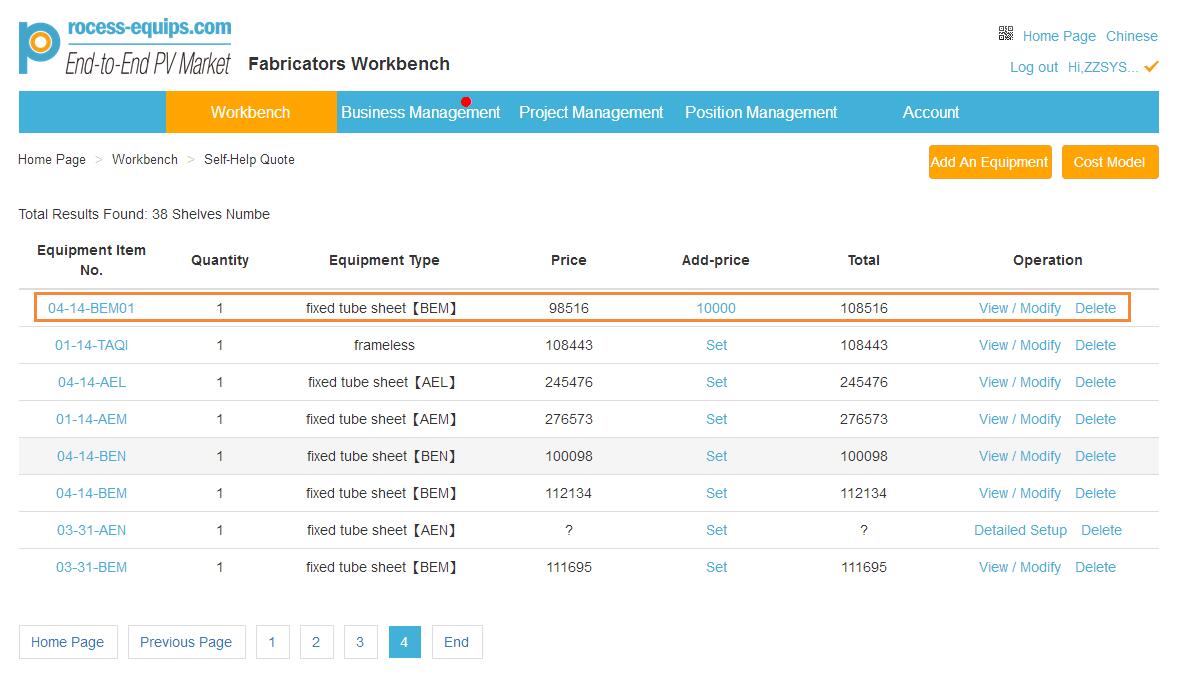

2. The intelligent quotation system has set up the purchaser’s self valuation function, that is to select one or more manufacturers, only need to input parameters of product design, we can get the equipment valuation from one or more manufacturers, so the quotation work will be completed immediately. Make waiting period of the traditional way from more than 10 days to 1~2 hours.

3.The intelligent quotation system solves the problem of the efficiency of the quotation at the same time. Through the actual test of the professionals, the efficiency of the quotation will be raised more than two times after the adoption of the intelligent quotation system

4.The intelligent system can offer corresponding cost estimation according to different manufacturers, a number of projects (such as different standards, or different materials or different design parameters) , through quantitative, feasible, multi program comparisons to realize the maximization goal of reducing project cost.