High salinity wastewater from chemical industry is currently produced in petrochemical, fine chemical, pharmaceutical and chemical industries. It is currently the largest and most difficult chemical wastewater.

Most of this kind of wastewater is not a single component, but the mixed wastewater of various salts, organic compounds usually contain high and volatile substances, easy to coke, due to high salinity, no direct biochemical treatment, but the wastewater after pretreatment method, after salt by evaporation crystallization or cooling crystallization separation then, enter or other biochemical processing unit, finally discharge or as process water reuse.

The routine treatment route for high salt wastewater of chemical industry is: pretreated &rarr, evaporating salt &rarr, condensate depth treatment &rarr, discharge or reuse.

Because the wastewater contains high organic and easy coking components, in evaporation before pretreatment, the easy coking organic matter separation into evaporation unit treatment, pretreatment needs a large number of experiments to determine the input, the right solution is whether the long-term stable operation of the evaporation unit of the key.

Evaporation unit is the core process of high salt wastewater treatment. There are many kinds of evaporation modes. At present, the widely used evaporation systems are divided into three types:

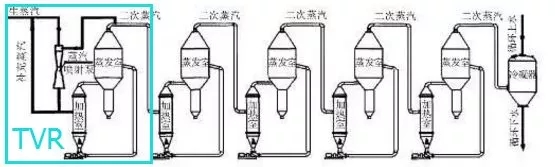

1, multi effect evaporation system (Multiple Effect Evaporation, MEE): the cascade utilization based on steam will connect several evaporators to operate.

2, heat pump evaporation system: using the external power or heat to improve the steam grade for two use.

Thermodynamic steam recompression evaporation system (Thermal Vapor Recompression Evaporation, TVR)

Mechanical vapor recompression evaporation system (Mechanical Vapor Recompression Evaporation, MVR)

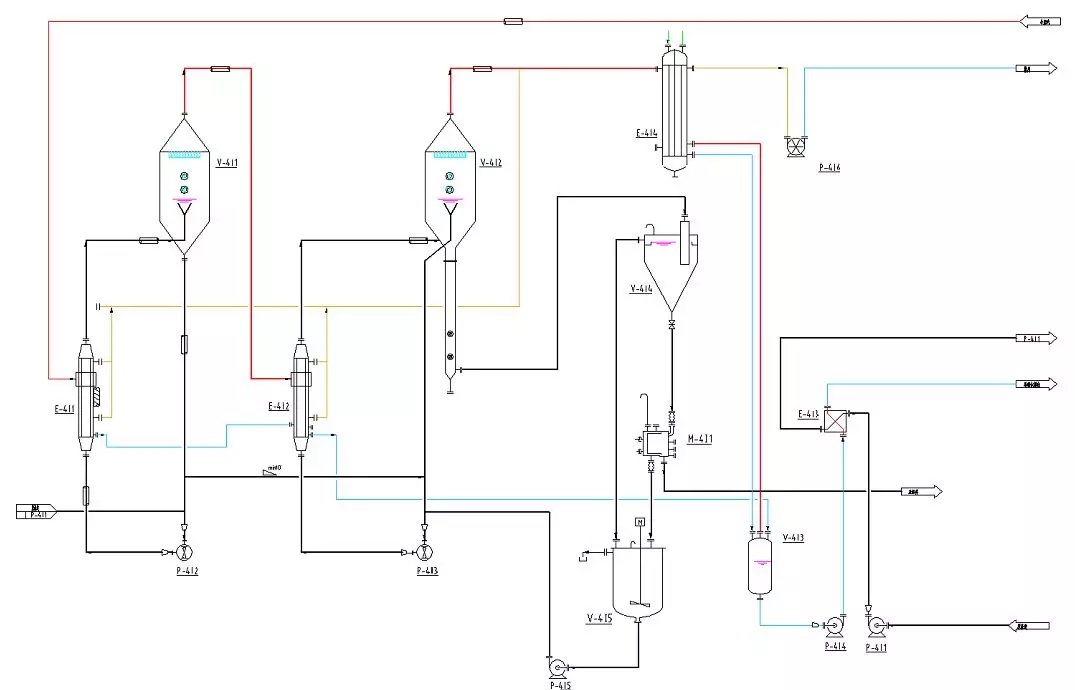

Multi effect evaporation system

Multi effect evaporation (MEE) is based on the cascade utilization of steam to connect several evaporators to improve the efficiency of thermal energy utilization. The advantage of MEE is that the water intake pretreatment is simple; the application is flexible, it can be used alone, and it can be used in combination with other methods; the system operation is safe and reliable.

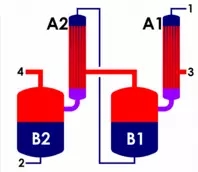

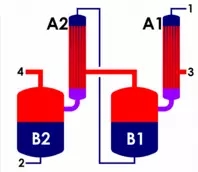

The 1 is the dilute solution of feed, the 2 is the completion fluid, the 3 is the steam generation, and the 4 is the two effect steam. The A1 and A2 are the one effect and two efficiency heater respectively, and B1 and B2 are respectively effective and two efficiency separators.

Flow diagram of multi effect evaporator

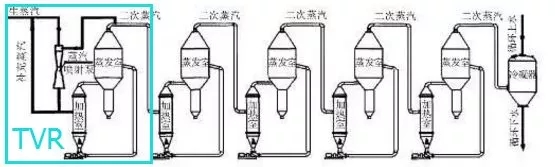

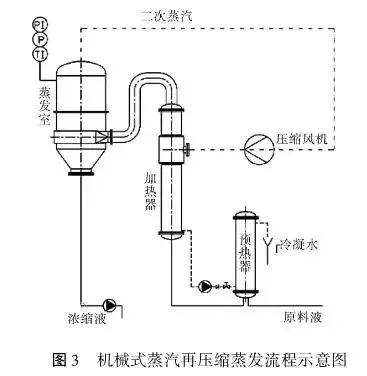

Thermodynamic steam recompression evaporation

According to the principle of heat pump, steam vapor is regenerated by steam vapor ejection heat pump. The steam is compressed by Venturi steam ejector heat pump and driven by a small amount of high-pressure steam. The steam is compressed and mixed into the heating chamber for heating steam two times.

A schematic diagram of thermodynamic steam recompression evaporation process

According to the characteristics of its efficiency, the energy saved by a thermal steam compressor is equal to the energy saved by an evaporator, so it is widely applied.

On the equipment, the TVR more effective evaporation system only adds the steam jet pump, and the combination of multi effect and steam jet pump is more energy saving than the simple multi effect evaporation. TVR technology is operated according to the principle of jet pump, without active components, the design is simple and effective, and it can ensure the high reliability of the operation. A certain amount of fresh steam still needs to be supplied continuously during the operation of the thermal steam compressor.

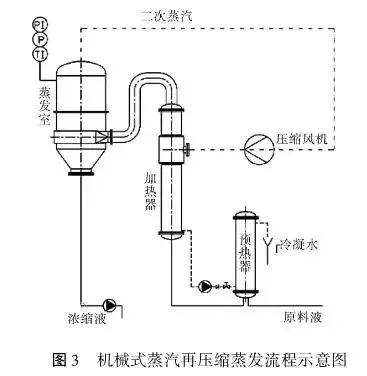

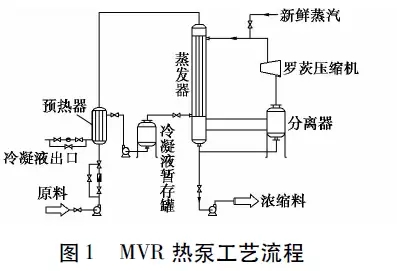

Mechanical steam recompression evaporation system

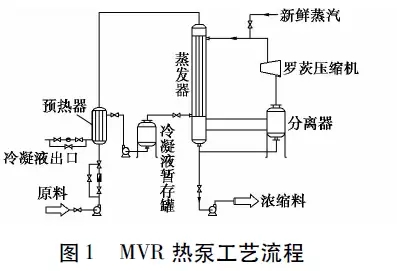

Mechanical steam recompression is also called mechanical thermal compression. The principle of evaporation is to use the axial flow or centrifugal compressor to compress the two steam and enter the heating room for heating steam.

During the start-up process, steam is supplied, and no steam supply is needed after normal operation. Therefore, the thermal efficiency is improved, the demand for external heat source is reduced, and the energy consumption is reduced. MVR adopts single effect operation, the retention time of the material and liquid is short, the energy consumption and operation cost are low, the land area is small, and the public works are small.

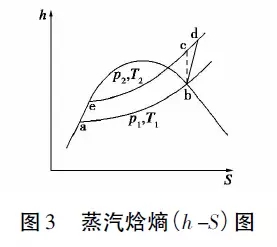

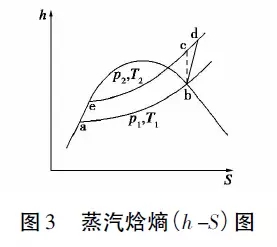

Raw material after preheat state after A (a), the liquid in the saturated liquid state; the liquid heated into the evaporator evaporation chamber absorbs heat boiling gasification to produce two steam, gas-liquid mixture through the separation effect of gas-liquid separator, concentrated liquid from the discharge pump outflow, the steam enters the two roots of compressor at the entrance of the steam is saturated steam in the specific evaporation pressure, the gas state parameters for B (B);

Two steam in the compressor under the effect of temperature, pressure, enthalpy of steam, the ideal case (isentropic compression) state of C (c), is an irreversible process and the system is not fully adiabatic actual steam compression process, the state parameter is D higher superheat (d), the shell of superheated steam at first after saturation treatment after entering the evaporator in the condensation of saturated condensate, the state of E (E).

The condensate first exists in the temporary storage tank and then the raw material is preheated by the pump to realize the comprehensive utilization of energy. The system needs to pass into the evaporator shell of fresh steam in the start of operation, once the system is running stable, can maintain the heat balance system using the latent heat of steam compression, only need to add a small amount of fresh steam can be more heat loss.

From the temperature entropy diagram can be seen, the heat pump system in MVR in the 2 and 3 temperature pressure condition, pressure change is the condensation of vapor compression pressure before and after the vapor compression evaporation pressure, temperature change is mainly evaporation temperature, superheating temperature after compression and compression saturated temperature.

From the enthalpy entropy diagram, the essence of the operation of the MVR system is to make a small amount of work by using the compressor.The heat enthalpy of high steam is used to reheat the raw material by releasing a large amount of condensing latent heat from the compressed steam. Because the latent heat of gasification (or condensation latent heat) accounts for the most part of the enthalpy of steam, therefore, the key to the normal operation of the heat pump system is to make full use of the latent heat of steam.

The main technical characteristic of MVR is to compress the two steam generated by the compressor, so that the steam pressure and temperature can be increased, and the steam with high taste can be obtained, and then it will be used as heating steam again. Therefore, the compression stage is the heart of the whole MVR evaporation system.

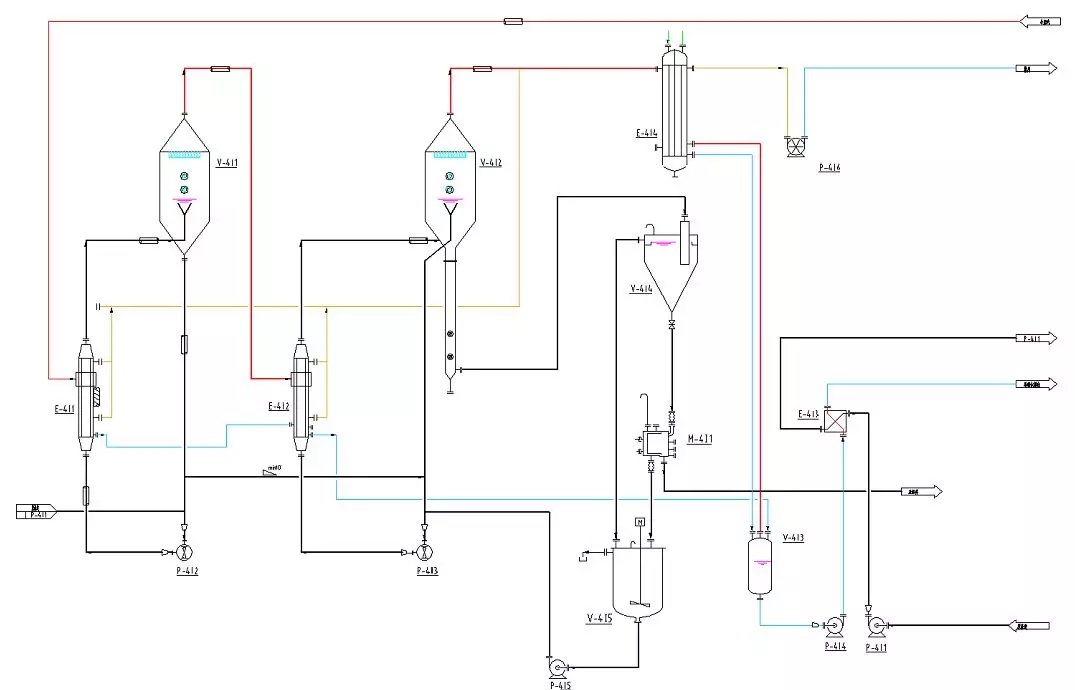

The three kinds of evaporation systems are not technically advanced and backward. They are relatively mature in technology, and choose economical and applicable evaporation modes according to multiple factors such as location, energy, physical properties and operation conditions.

The industrial wastewater produced in the production process of common salt content high, Rita technology according to different water quality, to provide customers for multi effect evaporation (MEE) and evaporation steam hot compression (TVR) and mechanical recompression evaporation (MVR) process system and supporting device; according to the characteristics of wastewater of salt. Through the optimization design and control equipment operating parameters, effectively solve the evaporation salt or salt plugging technology problem of pipes, to ensure stable operation and low energy consumption system.