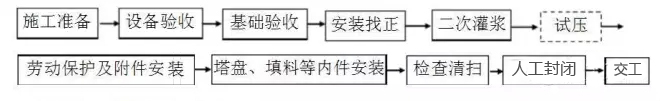

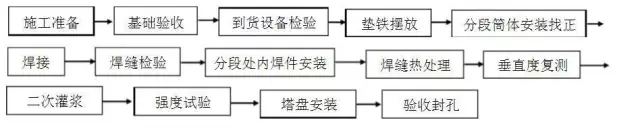

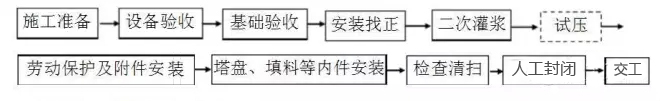

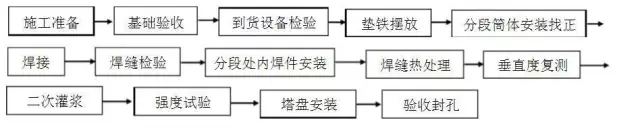

First, the construction procedures

1, the overall arrival of equipment construction procedures

2, section of the arrival of equipment construction procedures

Two, the main construction methods

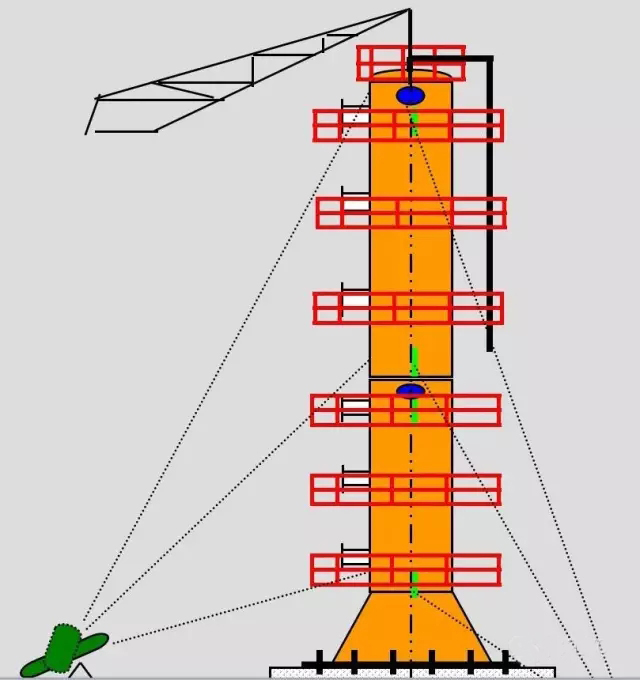

For direct lifting in place, a crane to take place to install the method of installation. For the equipment installed in the framework of the crane and manual hoist with a crane:

1) will not affect the equipment lifting the ladder platform as far as possible in the installation of the ground

2) the method of vertical group for welding

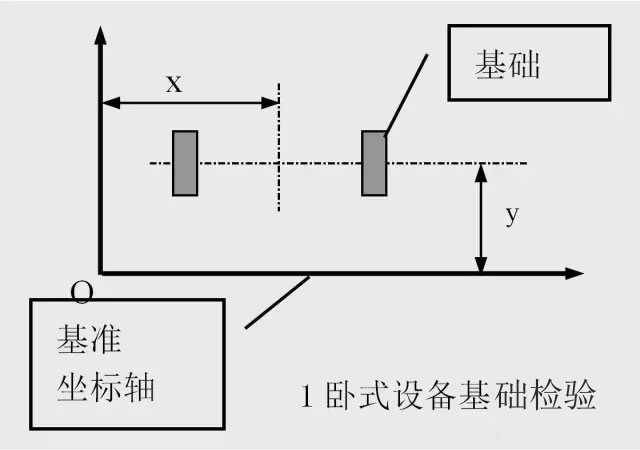

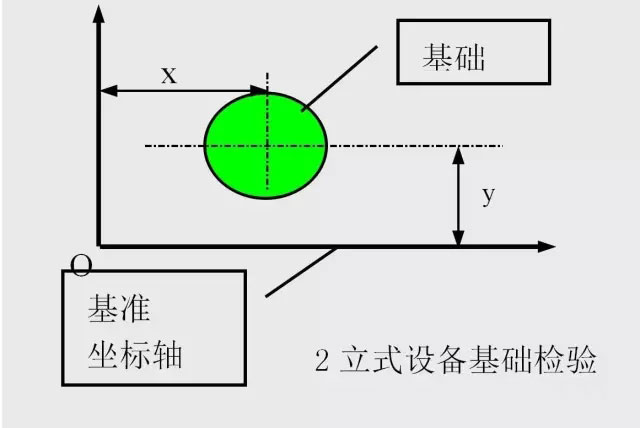

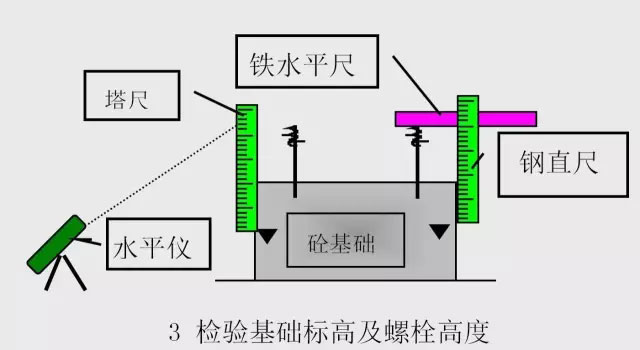

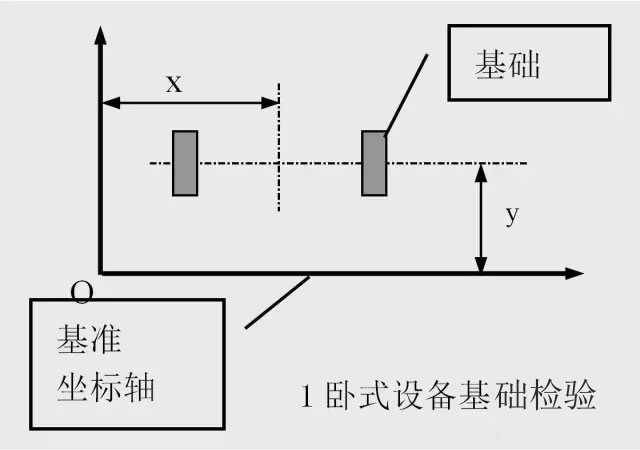

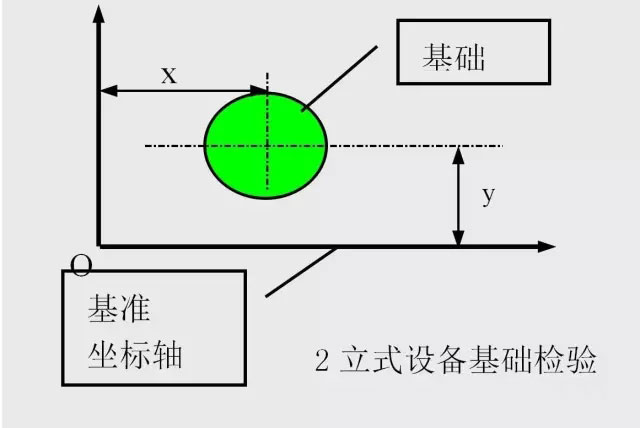

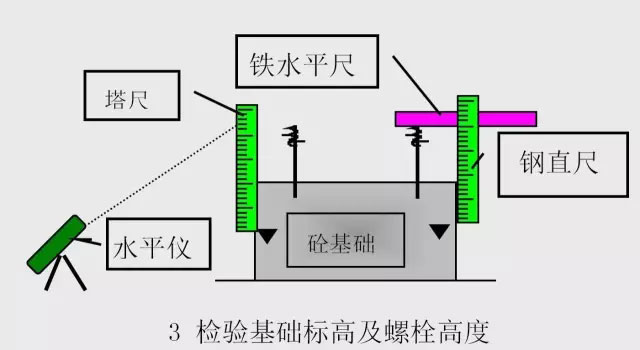

Prior to the installation of equipment, in accordance with the provisions and procedures for the timely and basic construction units for the transfer of equipment foundation. Basic construction units must provide the basis of the survey report and the construction quality certificate, based on the basic elevation and the vertical and horizontal line of the logo:

1) based on the surface no cracks, pits and oil

2) embedded anchor bolts without bending, thread damage, corrosion and protection measures

3) the sliding end of horizontal equipment should be smooth and flat.

4) the quality of the basis of re inspection shall be in accordance with the relevant standards and standards.

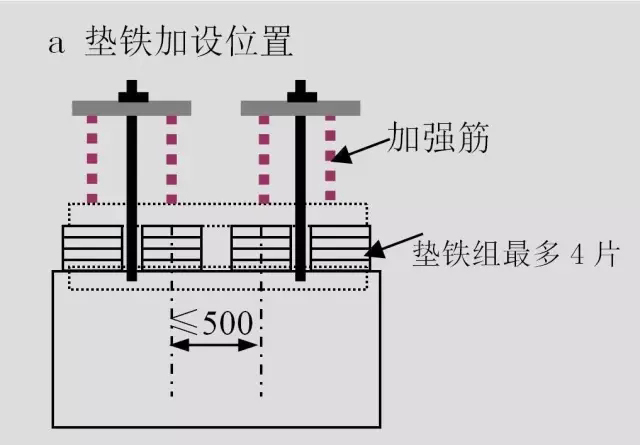

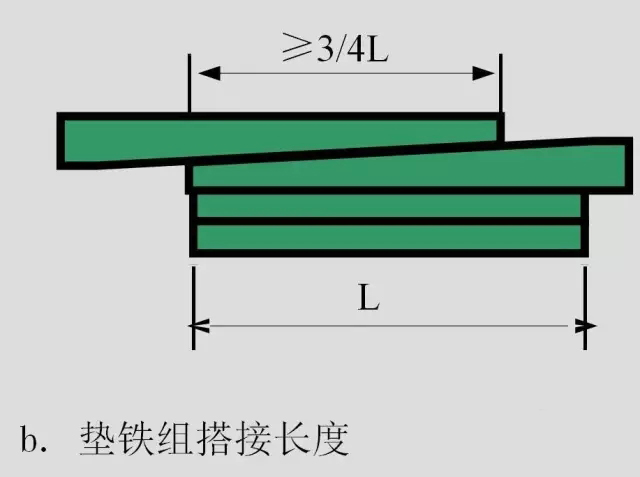

Placing iron

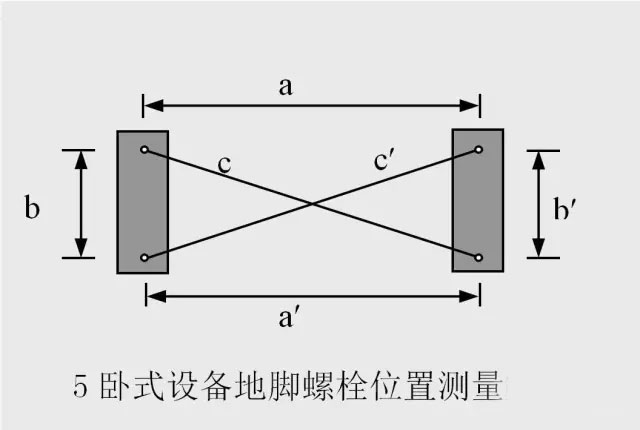

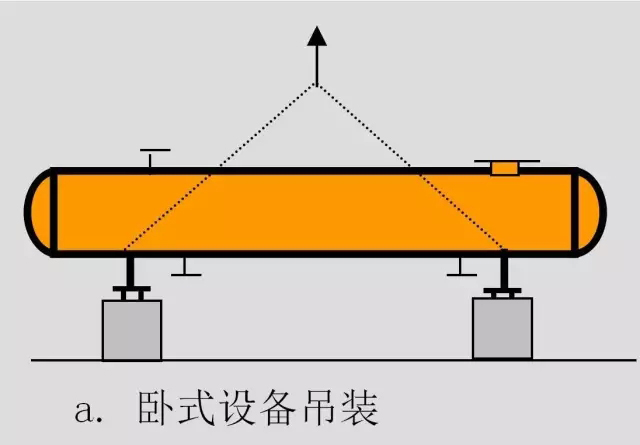

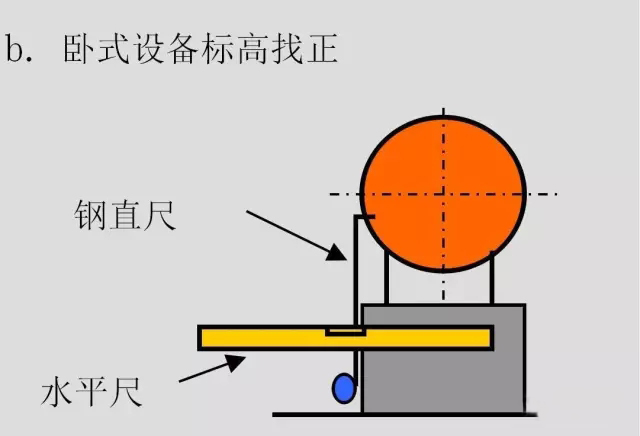

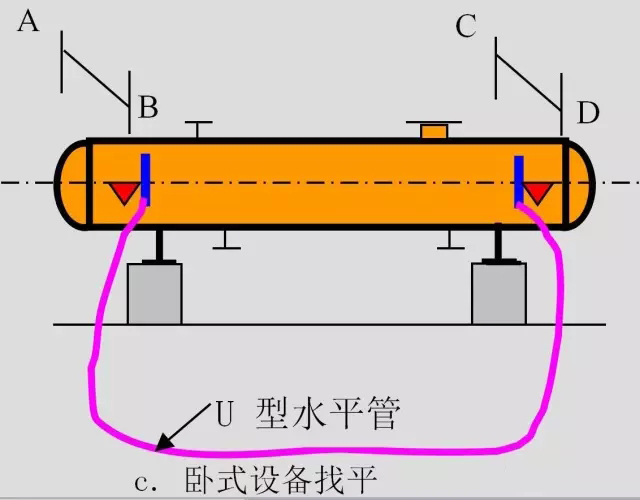

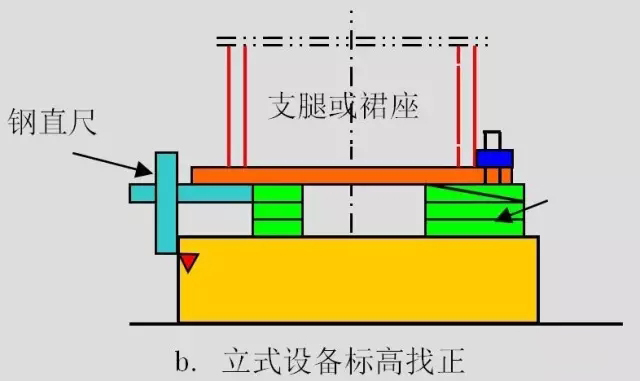

Horizontal equipment installation

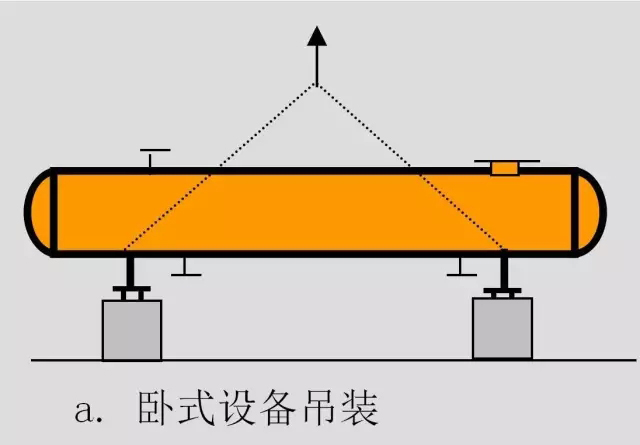

1, the use of nylon with a binding way to lift the hoisting

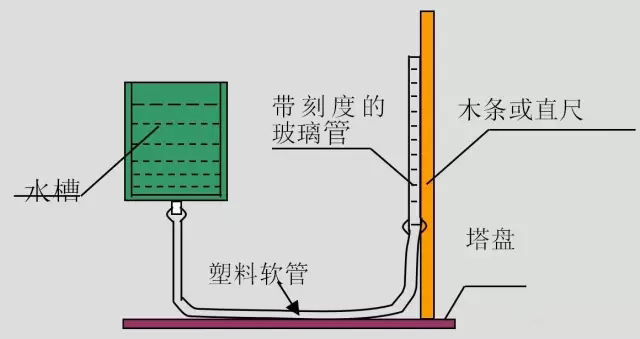

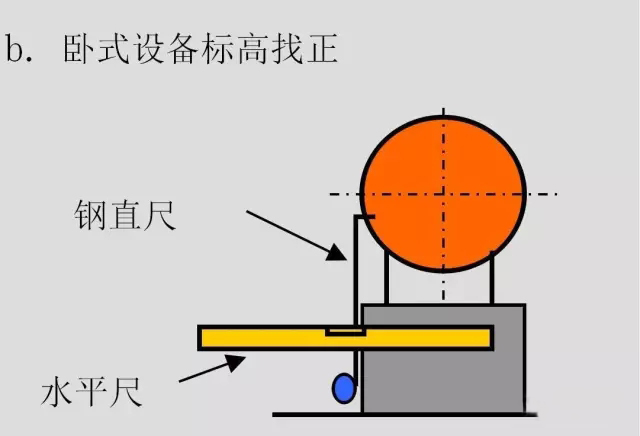

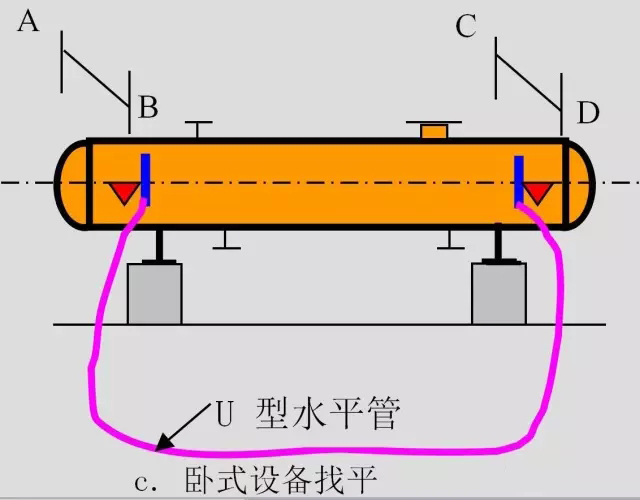

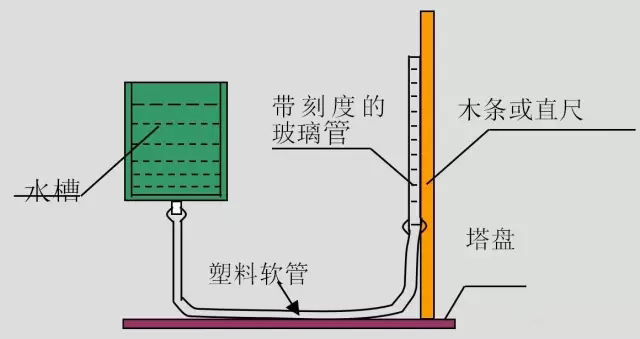

2, the horizontal center line of equipment, equipment level is iron level and steel tape; using U type glass tube for leveling on equipment level

3, when in place sliding end sliding plate should be coated with grease lubrication

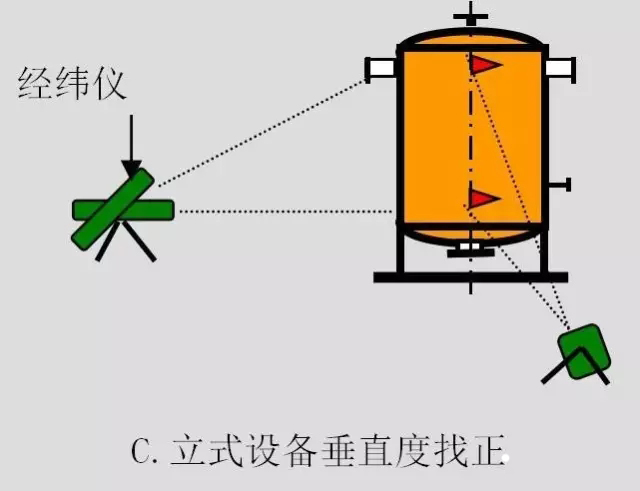

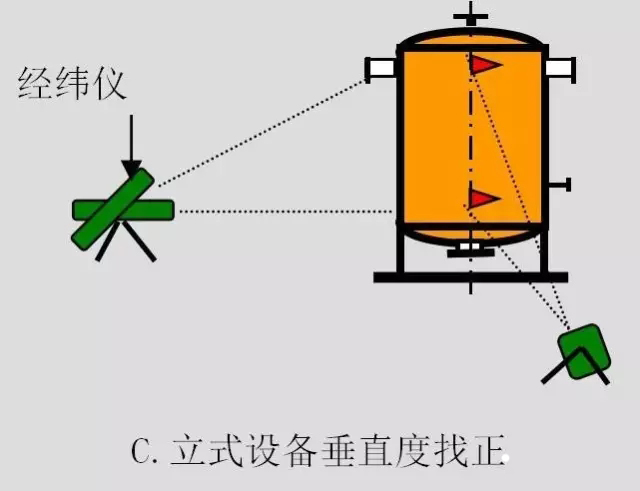

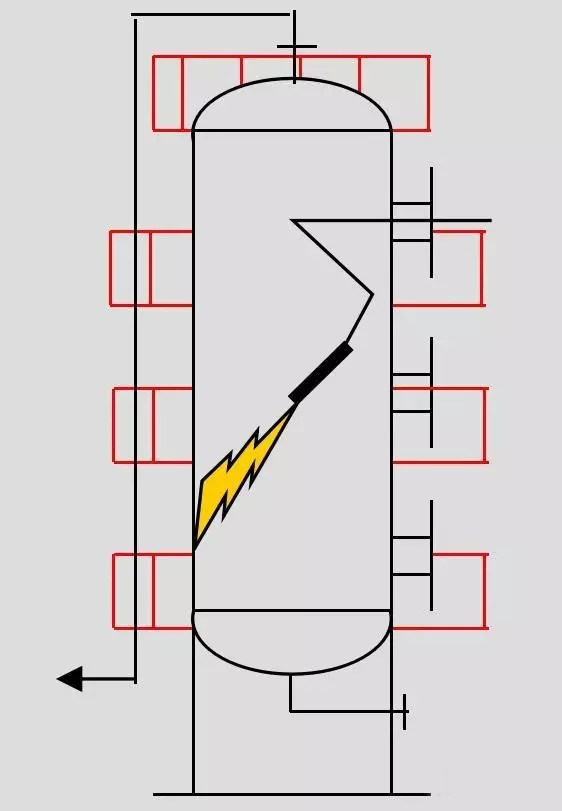

Vertical equipment installation

1, the overall vertical equipment installation

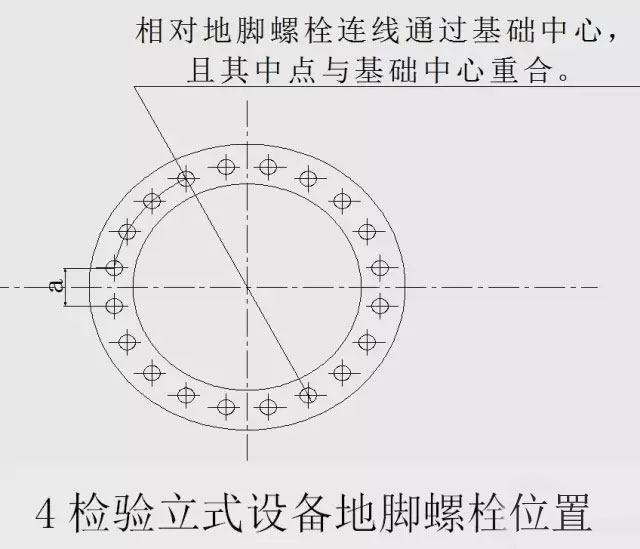

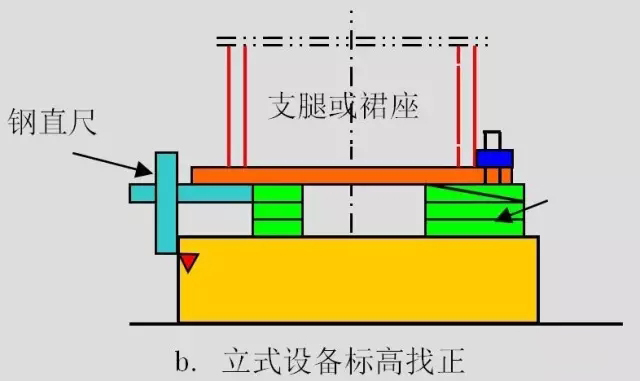

Lifting of the vertical equipment, in principle, the lifting of the lifting lug is adopted, and the method of binding without the lifting lug is carried out. The vertical equipment in place, adjust the equipment error within the allowed range

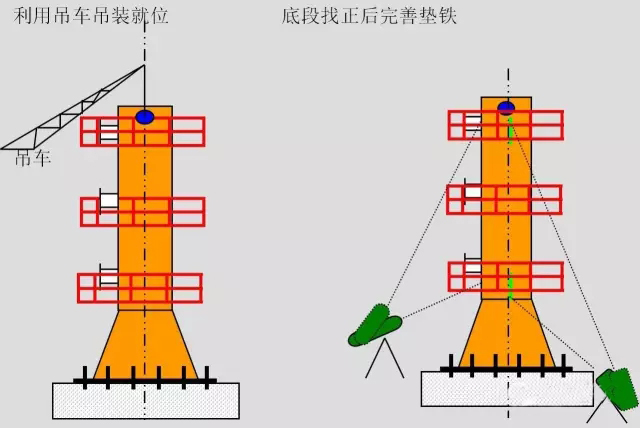

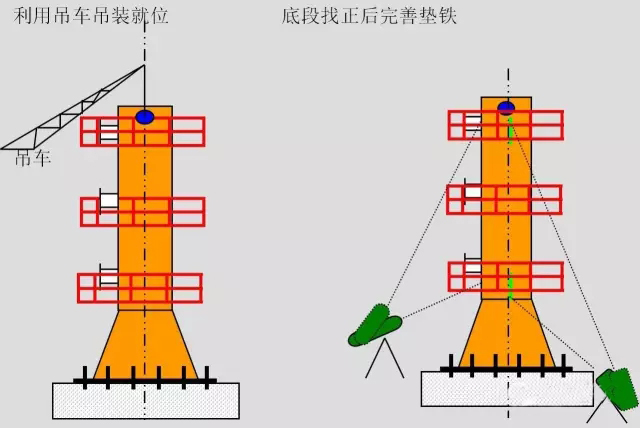

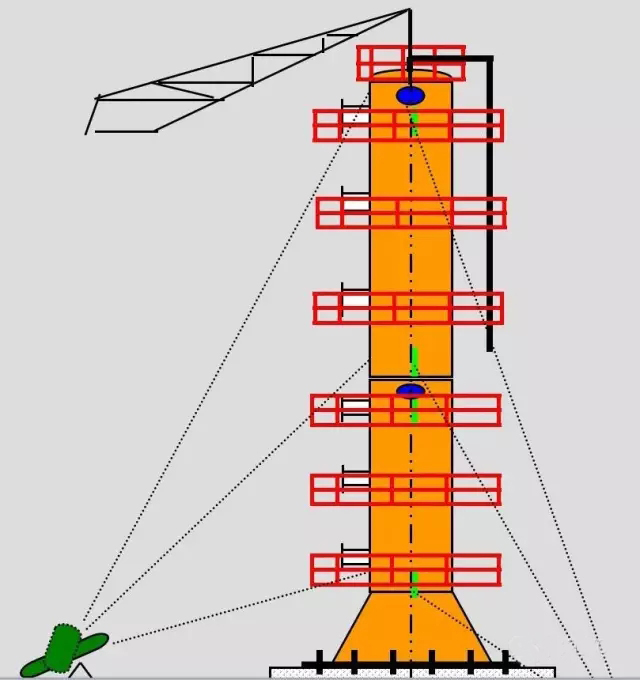

2, section equipment installation

Completion of the ground, the middle of the platform, hanging ear, insulation work

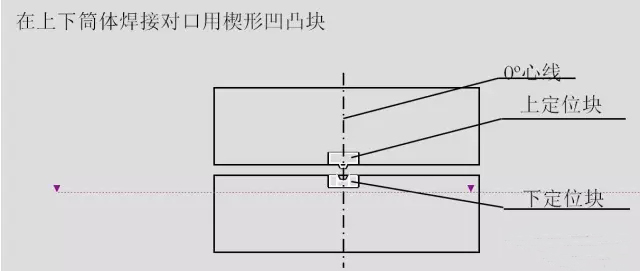

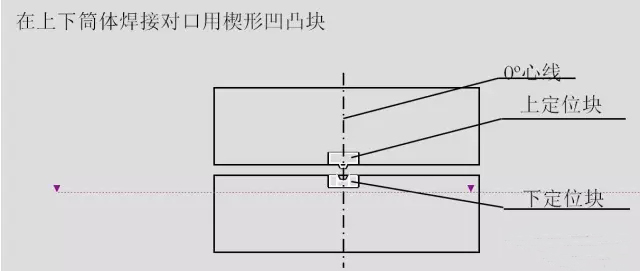

Other sections and the bottom section hoisting counterparts, is looking after the completion of welding, inspection

Will not affect the lifting of the labor protection installed in the ground, the bottom section of the tube in place to find the right:

— — the lifting of the upper cylinder, will not affect the lifting of the labor protection, with the tower of the pipeline in the ground installation

— — check equipment center line, the upper part of the cylinder lifting in place, the group on the interface and welding, inspection

— — welded joint inspection and acceptance of the internal and external welding parts

— — according to the drawing requirements to eliminate stress heat treatment

— — pressure test according to the drawings and specifications; the owner / Supervisor shall have the owner / Supervisor and the supervision department of the local safety supervision department.

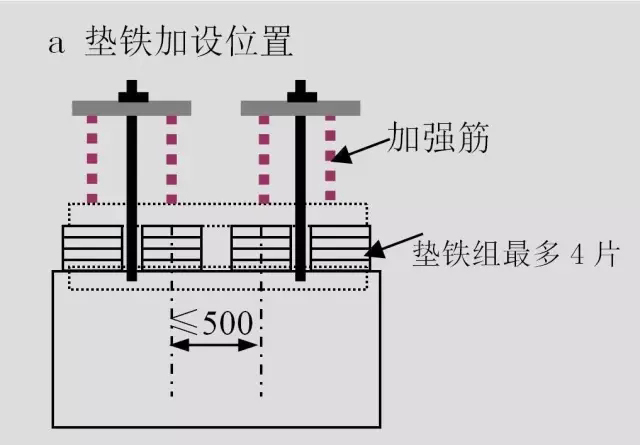

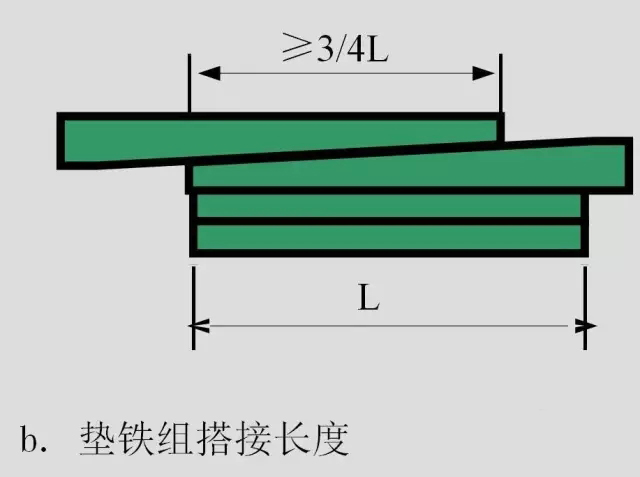

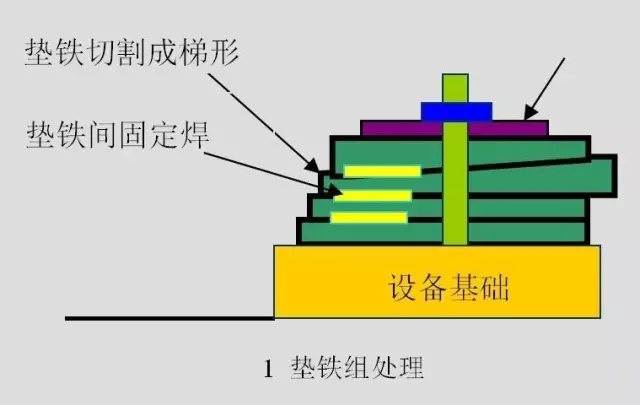

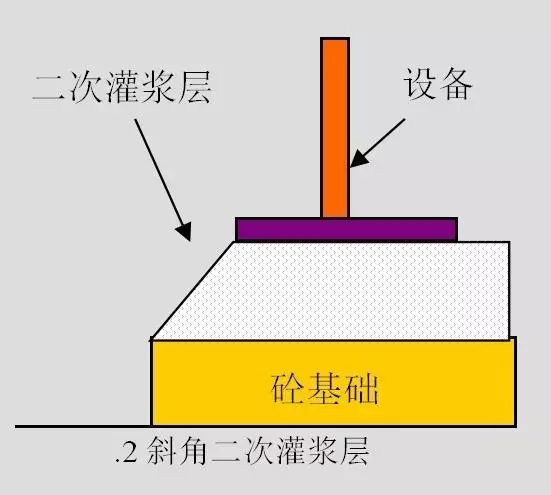

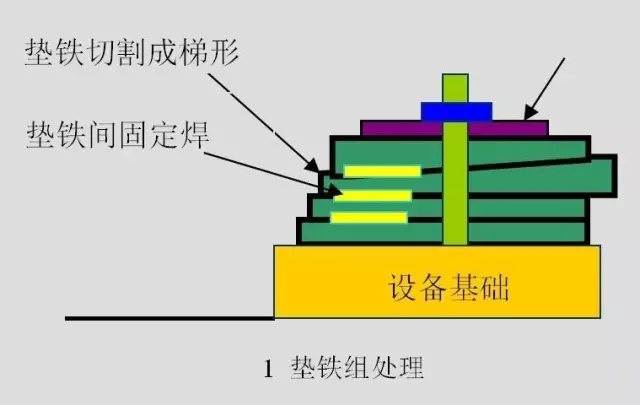

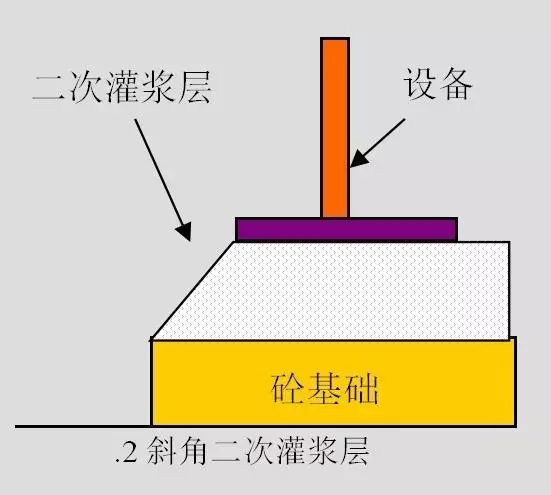

Treatment of iron pad group and two grouting

1, equipment installation and acceptance of the overall acceptance of the professional process after the handover, the equipment foundation for the two grouting

2, before grouting, water surface based on the clean and soak soak, and water blowing

3, a single piece of equipment after grouting; grouting layer of the outer margin of the base in accordance with the requirements of design and construction drawings trimmed into a rectangular or slope, do basic level and beautiful appearance

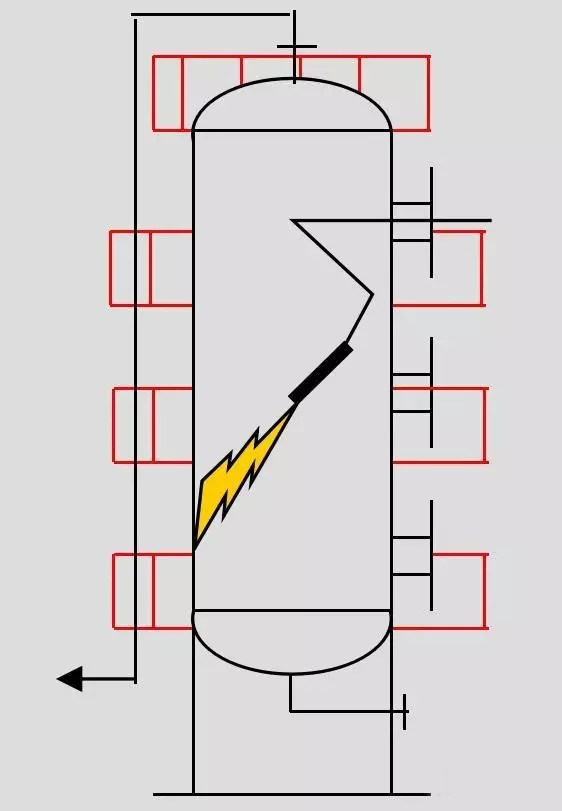

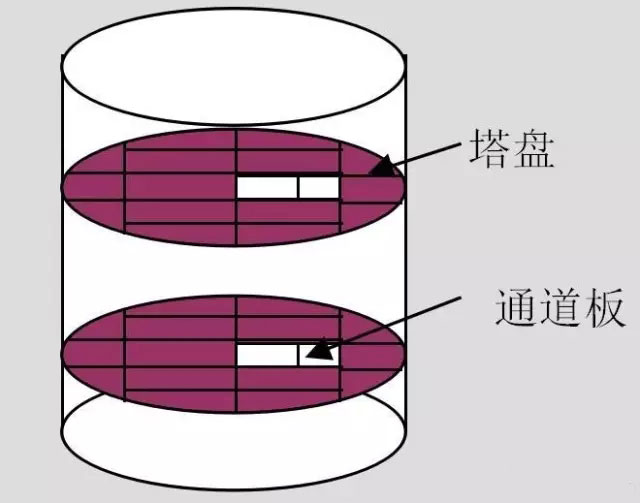

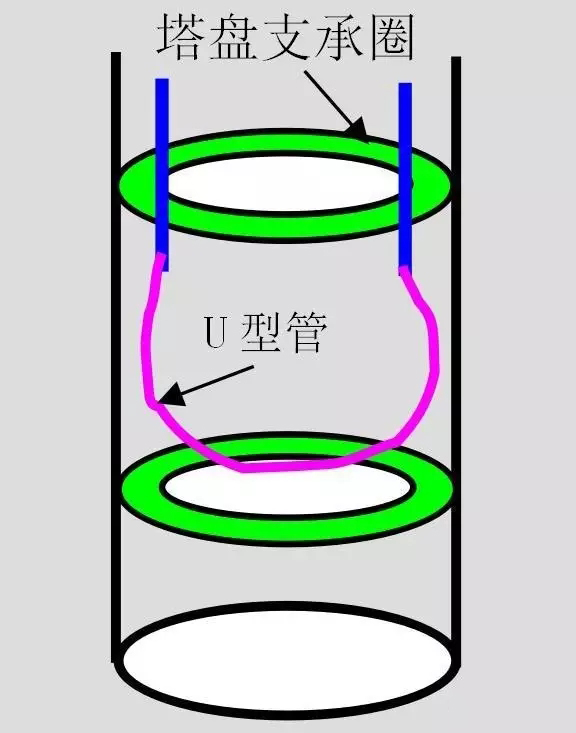

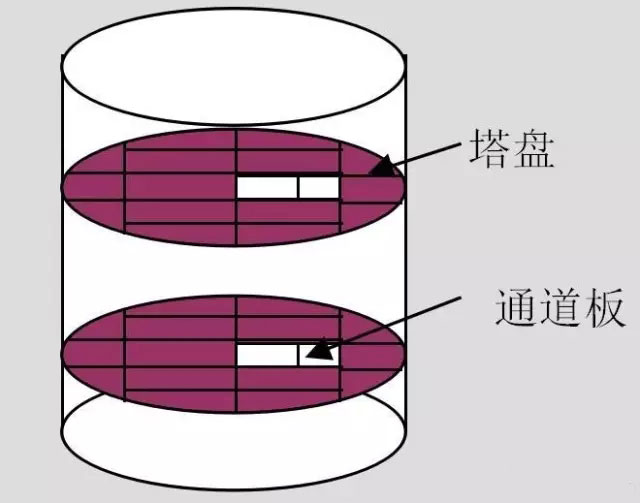

Tray installation

1, on the arrival of the tray for acceptance. The quantity and type of arrival shall meet the requirements of the design drawings, and the quality of the goods shall be in accordance with the requirements of the national standard.

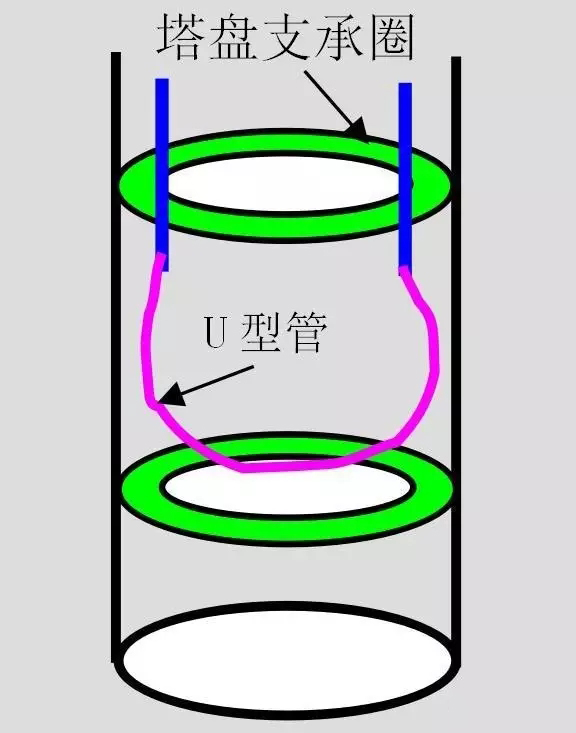

2, glass tube level layer check tray support ring level

3, installation of layered trays, each tray is installed by peripheral side plate to the center of the tower gradually, while the adjustment of fixed side installation

4, after the installation of layer level of tray and bolts, valve installation quality inspection, ensure that the overall quality of installation

5, channel board set aside, in the final test after passing layer closed

Derusting, clean the internal equipment

Test tube tray support ring of water by U

Derusting tray after inspection to the tower hoisting layered manhole location

Layered installation tray, the reserved channel sealing plate is installed on the front

To test the level of tray with U type tube level meter

Filler loading

1, in the ground equipment loading area, the packing is measured, and into the lifting hopper

2, clean up the internal equipment, and draw a variety of models of the filling height of the filling line

3, with a crane lifting hopper lifting equipment to the corresponding manhole on the platform, for filler filling operation

4, through the distributor to fill the packing. Control the loading speed, after loading a certain amount, the construction personnel into the equipment inside the packing scraping flat and density detection. For the fragile packing, can be used in the equipment internal water filling or construction personnel to enter the equipment inside the program to carry out loading

5, after loading is completed according to the actual loading quantity calculated packing density, compared with the theoretical value

6, filling process should be kept in a row, rainy day is not construction