[prospective] because the evaporator is widely used in chemical industry, so many people in the installation and commissioning of the evaporator, and the fault analysis of interest, Xiao Bian today and everyone together to discuss the evaporator installation and maintenance, fault analysis and other knowledge, let us proceed to the evaporator all rounder!

Evaporator is one of the most important parts in the four refrigeration system, the condensation of &ldquo at low temperature; liquid ” through the evaporator, the heat exchange with the outside air, “ gas ” heat absorption, to achieve the effect of refrigeration.

Equipment installation notes

1 evaporation equipment installation instructions

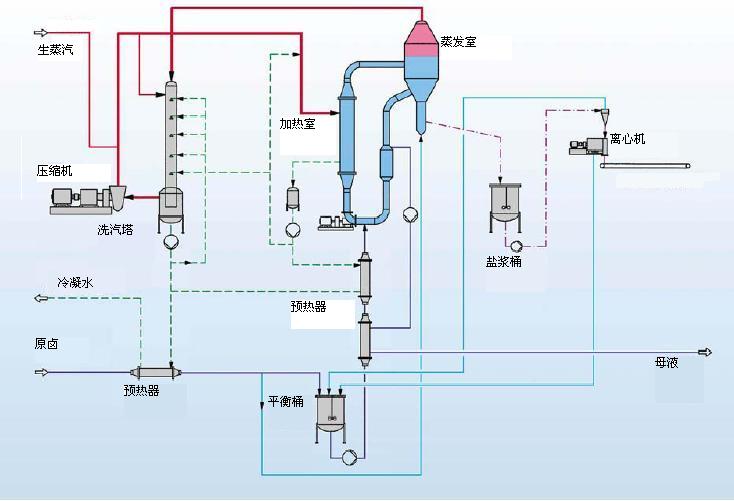

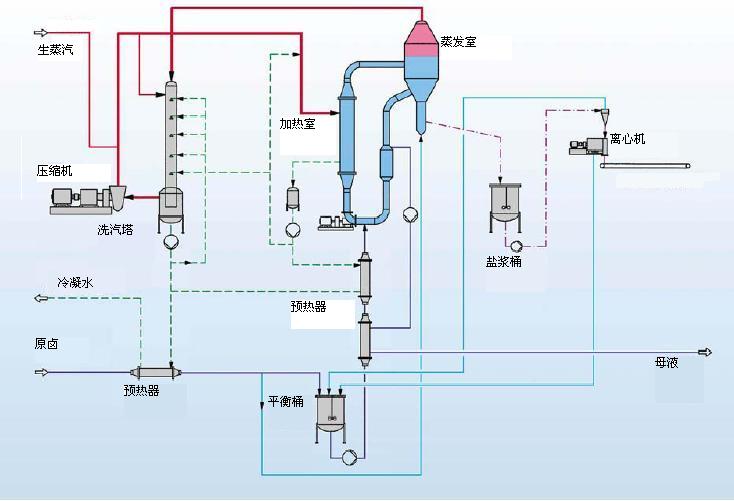

Familiar with the process flow diagram, equipment layout.

Familiar with the dimension of the equipment, characteristics, use and the relationship with other equipment.

The embedded iron plate prior to clean.

The ready lifting transport, and wire rope, wood, iron pad etc.. Have the rigger command at the scene, but also set up a full-time security staff.

According to the range of equipment nozzle.

According to the size of equipment positioning devices placed, avoid the equipment installation error is too large.

The level of pipeline to tilt along strike 5/1000.

2 evaporation equipment installation instructions

Installation instructions for heating room

The first heating chamber and a separation chamber together by the heavy, light up the light, according to the requirements of the verticality of equipment on the map.

The equipment is not installed before the horizontal placement, and the sleeper.

The equipment lifting process of light hanging light, avoid excessive vibration will bundle equipment nozzle and surface bumps.

Do not open the packaging process of the equipment in the installation of the equipment, to avoid the other hard objects fall into the heat exchanger tube.

The four branch of the AMP in the corresponding embedded iron plate, through the observation of vertical suspension guarantee.

Separation chamber installation instructions

Before installing the equipment, it is necessary to check whether the parts are complete, if the defects are replaced in time.

The device can only support in the process of lifting equipment, lifting force, is not allowed to take over, clamp, pipe and other weak force components, to light up the light so as not to damage, but not the thump.

Clean the inner surface of the equipment before installation.

The fastening flange and take over parts of the equipment should be installed. The principles of chemical containers, symmetrical, uniform requirements gradually tightened, so as to avoid excessive local stress damage, such as found in the demolition process of gasket lose elasticity should be replaced.

With the reaction tank with mirror glass is a kind of brittle material, when installed in addition to ensure uniform, clamping force should not be too large. Such as local leakage plugging partial pad, avoid excessive local stress rupture.

The equipment after installation, deal with all kinds of parts and can check carefully after confirmation of cargo transfer.

The use is not allowed to add a small amount of material or empty tank heating equipment to prevent entrainment of internal material added to bulk metal or debris.

Commissioning note

1 necessary conditions for normal operation

Centrifugal pump mechanical seal must ensure that no quality problems, or must be replaced, so as not to affect the evaporator heating chamber condensate can not be extracted, and affect the vacuum. During the operation of the pump, water is always supplied.

Each part of the device, especially the evaporating pipe must be cleaned regularly.

Increasing the cooling water quantity or reducing the cooling water temperature can improve the vacuum degree. Vacuum also can be adjusted by the vent valve three effect separator.

2 preparation work before driving

Check whether the lubrication parts of each unit have lubricating oil, and whether the motor is correct.

Open the cooling water of all pumps to ensure the smooth flow of cooling water.

3 matters needing attention

The first heater of the evaporator must install a safety valve, the steam pressure in the first effect heater shall not exceed 0.01Mpa. Should always check whether the safety valve failure. Don't be careless.

In any case, close the steam valve.

When the evaporator circulation pump failure to stop running, to close the steam immediately.

The regular check operation of the pump, the oil level is normal, the cooling water quantity.

The regular observation of motor current and motor temperature of each device.

In any case prohibited any effect of cutting, adjusting the evaporator liquid level to the slow, no flickering.

When the equipment working environment at a temperature of 0 DEG C, the equipment and pipeline of the water discharge, in order to avoid frozen or blocked pipeline.

Maintenance and maintenance

Found run, run, drop timely solution.

Cleaning the evaporator tube in order to prevent the blockage of the pipe and the effect of heat transfer and evaporation.

Lubricating oil lubrication.

It should be replaced when the pump mechanical seal damage.

If the thermometer, vacuum gauge, pressure gauge and other instruments are not allowed when the index should be timely proofreading or replacement.

Common failure analysis

Due to the change of operating conditions, usage and other factors, it often leads to the failure of the equipment to run normally, and even the concentration process is interrupted. Therefore, it is essential for the operation and maintenance of the equipment to understand the normal operation conditions and operation methods.

Failure during operation of evaporator:

1 vacuum is too low

The low boiling point of vacuum through the concentrated liquid and two steam temperature increase, thereby reducing the effective temperature between the heating steam and concentrated liquid, which reduces the heat transfer, reduces the steam evaporation rate, and the feed liquid heating temperature,Affected the preservation of active ingredients. Vacuum is too low, in addition to affecting the concentration of quality, but also reduces the production capacity of the equipment.

The reasons for the low vacuum are as follows:

The leakage of air leakage of each part of the condensed equipment. The infiltration of air has added extra burden to the vacuum equipment, which can lead to the loss of time.

Insufficient cooling water. In addition to the reasons for the pump equipment, cooling water shortage is mainly due to pipe blockage, valve damage caused by. If the cooling water is not enough, the two steam can not be condensed in time.

Cooling water temperature is too high. The inlet water temperature of the cooling water is too high, and a large number of two times of the concentrated heating can not be condensed in time.

The use of high pressure steam. The heating steam pressure is too high to increase the evaporation rate of the concentration equipment, and the production of a large number of two steam aggravates the load of the cooling equipment, so that the vacuum degree decreases gradually. The reduction of vacuum degree and the evaporation temperature of the material, in addition to affecting the quality of the product, and ultimately reduce the production capacity of the equipment.

2 vacuum degree is too high

Cause of high vacuum:

The cooling water inlet temperature is too low, so that the vacuum of the equipment is too high. Although the high vacuum increases the effective temperature between the heating steam and boiling point of the material, improve the heat transfer and evaporation rate, but because the two steam latent heat of vaporization is increased with the increase of the vacuum, the corresponding increase of steam consumption.

Due to the low steam pressure and steam flow rate, the evaporation rate is greatly reduced.

In the use of steam and water separator enrichment equipment, due to the condensation of steam and water separator caused by condensation of water is not good, so that the water heater serious. In addition, if the poor quality of steam heating, steam pipeline insulation and cold side, also make the heater water seriously, so that the heat transfer is difficult, the high degree of vacuum.

The serious coking heater surface reduces the heat transfer coefficient of the heating surface, the evaporation rate decreased so that the vacuum pot exceeds the standard.

3 cooling water enters the concentrating equipment

The sudden power outage for making the vacuum degree is higher than the vacuum system. This is not timely close the steam boiler destroyed, vacuum, cooling water will be in vacuum system from entering the concentrating equipment.

There is no operation in normal sequence (destruction of vacuum equipment to shut down in the equipment stops after), making the instantaneous vacuum above the vacuum system, the cooling water will flow backward.

The sudden failure of vacuum equipment to the vacuum system of the pumping rate dropped sharply, in this case, the vacuum failure did not take timely measures, the cooling water will flow backward.

4 surface coking heater

The feed material concentration inside the equipment volume is small, the heating surface is not all materials and open the steam valve is submerged, the exposed surface and heating of coke. A sudden rise or sudden changes in the operating conditions when the heating steam pressure feeding operation and interruption in the process, may cause serious coking heating surface.

Do not operate according to the parking order