Preface

Petroleum and chemical industry occupies a very important position in the national economy, chemical process pump as a key supporting equipment is also more and more people's attention. Due to the complex nature of chemical media, coupled with the continuous improvement of environmental protection requirements, how should we choose the chemical pump? Should pay attention to what aspects and so on is particularly important. Today, Xiao Bian came to talk with you about the selection of chemical pump should pay attention to matters!

Note 1: corrosion problems

All along, the corrosion is one of the most headaches of chemical equipment, a little careless, light damage to the equipment, causing serious accidents and even lead to disaster.

According to statistics, about 60% of the destruction of chemical equipment is caused by corrosion, so the first choice in the selection of chemical pumps should pay attention to the scientific nature of the selection.

Usually there is a misunderstanding that stainless steel is “ universal material ” no matter what the media and environmental conditions are holding out stainless steel, which is very dangerous.

Below for some commonly used chemical media talk about the main points of selection:

1 sulfuric acid

As one of the strong corrosive medium, sulfuric acid is an important industrial raw material.

Corrosion difference of different concentration and temperature of sulfuric acid material is large, the sulfuric acid concentration is above 80%, the temperature less than 80 DEG C, carbon steel and cast iron has good corrosion resistance, but it is not suitable for high-speed flow of sulfuric acid, not suitable for ordinary stainless steel valve materials; such as 304 (0Cr18Ni9), 316 (0Cr18Ni12Mo2Ti) the sulfuric acid also of limited use.

Therefore, the delivery of sulfuric acid pump valve is usually high silicon cast iron (casting and machining difficult), high alloy stainless steel (alloy 20) manufacturing, but its processing is difficult and expensive, so people are not optimistic about.

Fluorine plastic alloy with good resistance to sulfuric acid good performance, it is Chinese Academy of Sciences, Shanghai Institute of organic chemistry, the patent materials, proved by the Chinese Academy of Sciences, yet which can react with the chemical medium, so using fluorine pump (F46) is a more economical choice.

2 hydrochloric acid

Most of the metal materials are not resistant to hydrochloric acid corrosion (including a variety of stainless steel materials), molybdenum containing high silicon iron can only be used for 50 C, below 30% hydrochloric acid.

And metal materials, the vast majority of non-metallic materials have good corrosion resistance to hydrochloric acid, so lined with rubber and plastic pumps (such as engineering plastics, fluorine plastic, etc.) is the best choice of hydrochloric acid transport.

3 nitric acid

Most of the general metal corrosion in nitric acid was rapidly destroyed, stainless steel is the most widely used nitric acid resistant materials have good corrosion resistance, all concentrations of nitric acid at room temperature, it is worth mentioning that the stainless steel containing molybdenum (316, 316L) on the nitric acid corrosion resistance is not only no better than ordinary stainless steel (such as 304 321), sometimes even better. For the high temperature nitric acid, usually use fluorine plastic alloy material.

4 acetic acid

It is one of the most corrosive substances in organic acids, ordinary steel will be severe corrosion in all the acetic acid concentration and temperature, acid resistant stainless steel is an excellent material, but also 316 stainless steel containing molybdenum for high temperature and dilute acetic acid vapor.

For high temperature and high concentration of acetic acid or contain other corrosive media and other harsh requirements, can choose high alloy stainless steel or fluorine plastic pump. Such as CQB magnetic pump, CQ stainless steel magnetic pump.

5 base (sodium hydroxide)

General corrosion is not very strong, but generally will have a crystalline alkali solution, FSB fluorine alloy pump so you can use the configuration of the silicified graphite mechanical seal material 169.

6 ammonia (ammonium hydroxide)

Most metals and non metals in liquid ammonia and ammonia (ammonium hydroxide) in the corrosion is very slight, only copper and copper alloy should not be used. Then select CQF engineering plastic magnetic pump, FSB fluorine alloy centrifugal pump is better.

7 salt water (sea water)

Ordinary steel in Sodium Chloride Solution and sea water, salt water corrosion rate is not high, are generally required to use paint protection; all kinds of stainless steel has a very low corrosion rate, but may be due to localized corrosion caused by chloride ions, typically 316 stainless steel is better.

8 alcohols, ketones, esters, ethers

Common alcohols media are methanol, ethanol, ethylene glycol, alcohol, ketones medium with acetone and butanone, a variety of media methyl esters, ethyl ester, ether medium with ether, ethyl ether, butyl ether, etc., they basically do not corrosive, and therefore may use an ordinary stainless steel, should also make a reasonable choice according to the media the properties and requirements of the specific use.

It is also worth noting that ketones, esters, ethers are soluble in a variety of rubber, the choice of sealing materials to avoid mistakes. Recommend the use of inorganic sealing fluorine plastic magnetic pump.

There are many other media can not be introduced here, in short, the material must not be arbitrary and blind, should be more access to relevant information or learn from mature experience.

Note two: sealing problem

No leakage is always the pursuit of chemical equipment, it is this requirement led to the application of magnetic pump is growing.

However, there is still a long way to go, such as the isolation of the life of the pump, the hole erosion of the material, the reliability of the static seal, etc..

Some of the basic aspects of the seal is briefly introduced as follows:

1 seal form

For the static seal, usually only two types of gaskets and seals, and seals to the most widely used O ring.

For the dynamic seal chemical pump is seldom used in packing seal, mechanical seal, mechanical seal and single face and double face, balanced and unbalanced type, balance type seal for high pressure medium (usually pressure greater than 1.0MPa), double end sealing machine is mainly used for high temperature, crystallization, viscosity containing particles and toxic volatile medium, double end mechanical seal should be injected into the isolation liquid to the sealing cavity, the pressure is generally higher than the medium pressure 0.07~0.1MPa.

2 sealing material

Static sealing material for chemical magnetic pumpMaterial generally fluorine rubber, under special circumstances the use of PTFE material; mechanical seal ring is more critical of the material configuration is not the best of carbide carbide, high prices on the one hand, the hardness difference between the two is not reasonable, so the best according to the characteristics of different media.

(Note: the typical configuration of the American Petroleum Institute API 610 eighth edition of mechanical seal and piping systems have more detailed regulations in Appendix D)

Note three: viscosity problem

The viscosity of the medium has a great influence on the performance of the pump, when the viscosity increases, the pump head curve decreases, the best conditions of the head and flow are decreased, while the power will rise, thus reducing efficiency.

The parameters of the general samples are the performance of the water, when conveying viscous medium should be converted (different viscosity correction factor can be used to refer to the relevant conversion chart).

For the higher viscosity of slurry, paste and viscous liquid delivery, it is recommended to use mortar pump.

Pump selection principle

Design Institute in the design of equipment, to determine the use and performance parameters of the pump and select pump type. First of all, this choice from the choice of the type and form of the pump, then what principle to select the pump? What is the basis?

1, so that the selected pump type and performance to meet the requirements of the flow, head, pressure, temperature, cavitation, suction and other process parameters.

2, must meet the requirements of media properties

For the transport of flammable, explosive toxic or valuable medium of the pump, the requirements of the shaft seal is reliable or the use of non leakage pump, such as magnetic drive pump (no shaft seal, the use of isolated magnetic indirect drive);

To transport corrosive medium of the pump, requires the use of corrosion resistant parts of convection materials, such as fluorine plastic corrosion resistant pump;

On the delivery of solid particles containing the medium of the pump, requiring the use of wear-resistant components convection parts, if necessary, with the use of clean liquid seal.

3, mechanical requirements of high reliability, low noise, small vibration.

4, the correct calculation of pump input costs.

5, transport corrosive media (such as sulfuric acid, concentrated nitric acid “ ”), transport flammable and explosive medium, use of the environment without any pollution: the choice of magnetic pump, such as “ CQB series magnetic pump, IMD series magnetic pump, for self absorption, can choose FZB fluorine plastic suction pump.

6, IHF and FSB centrifugal pump has the characteristics of high speed, small size, light weight, high efficiency, large flow, simple structure, no pulse infusion, steady performance, easy operation and convenient maintenance, such as the use of condition without special requirements, can be used pump well.

7, transport medium containing solid particles of chemical pump for convection component wear-resistant materials: UHB mortar pump is the best choice of objects, UHB corrosion resistant materials for high-strength mortar pump new engineering plastics UHBWPE, it is a kind of modified ultra high molecular weight polyethylene (more than 5 million). In plastic, it has excellent abrasion resistance, experimental contrast, its wear resistance is much higher than stainless steel, and impact resistance, creep resistance and excellent corrosion resistance (equivalent to F4), there is no unique properties such as adhesion.

8, when the medium level in the pump installation position below: should choose FZB fluorine plastic self-priming pump, such as the need to meet the characteristics of the magnetic pump, ZMD fluorine plastic self-priming magnetic pump

9, according to the performance curve of the pump to select the best specifications and models: when the use of performance requirements in the form of the table can not find a suitable model can refer to the pump performance curve to select the most suitable pump type.

How to choose these situations?

1 transport containing solid particles of acidic water, the choice of what pump?

Q: we need to transport a little corrosive media (acidic water), which contains about 20% of the solid particles, would like to choose a corrosion resistant pump?

Answer: if the corrosion is not very strong, can choose UHB-ZK series of corrosion resistant mortar pump, its internal flow components all adopt ultra high molecular weight polyethylene corrosion resistant well made, can be transported with solid content of not more than 40%, corrosive medium, and long service life, easy maintenance.

If the corrosion is very strong, it should be selected fluorine plastic centrifugal pump, supporting corrosion resistant wear resistant machine seal.

2 medium temperature is very high, corrosive, with what pump?

Q: we need to transport the medium temperature is very high (about 140 degrees), corrosion is very strong (glacial acetic acid), we would like to use a kind of non leakage, corrosion resistance of the pump, I would like to ask what the pump?

Answer: recommended IMD high temperature type fluorine plastic magnetic pump concrete pump shell material: selection of fluorine plastic alloy (F4/F46), impeller, isolated sets of components such as selection of PFA (PFA), high temperature up to 180 degrees, and good corrosion resistance.

3 transport medium corrosion is very strong, the pump?

Q: we need the transmission medium for aqua regia, room temperature, the pump is what?

Answer: recommend the use of fluorine plastic pump, fluorine plastic is one of the best corrosion resistant material.

4 transport medium corrosion is a bit strong, the choice of what pump?

Q: we need to transport the medium for the concentration of 30% hydrofluoric acid, the temperature of about 40 degrees, the election of what pump?

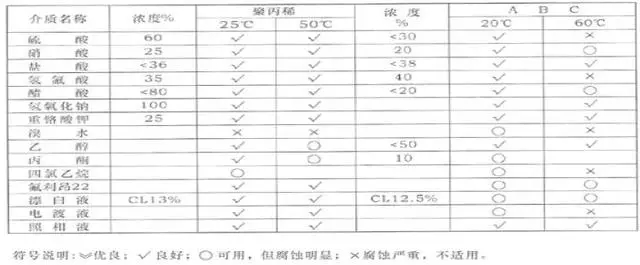

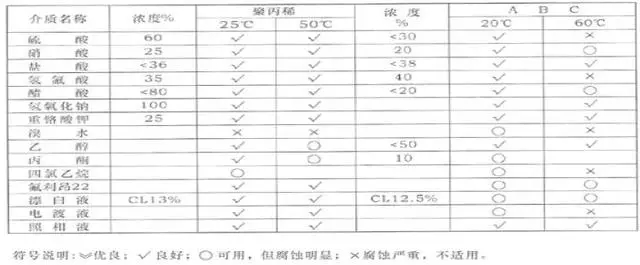

Answer: can choose engineering plastics (reinforced polypropylene) pump, engineering plastic pump can transport the medium range is as follows:

If the medium can be found in the above table, the following engineering plastic pumps are listed below:

1, CQF engineering plastic magnetic pump

2, FUH engineering plastic centrifugal pump

3, QBY engineering plastic pneumatic diaphragm pump

The belated effort of chemical, if you have any questions or questions on the content of the article, please leave a message, thank you!