Thread, deal with every day

Time is long

Domestic, foreign, metric, british,

Straight, conical, sealed, unsealed,

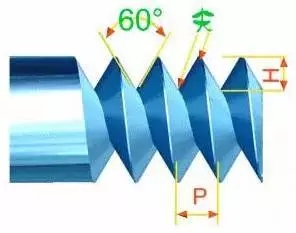

Inside, outside; 55° 60°.

In short, it's often confused,

Check it once in a while

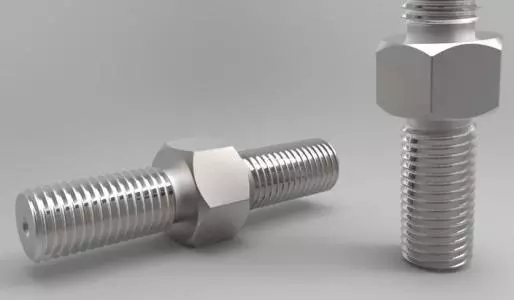

There are three major categories for use:

First, connect the thread, used for fastening, that is bolt nut;

Second, the transmission thread, that is, the kind of lathe knife;

Third, pipe thread, pipe connection.

According to the standard, there are the following:

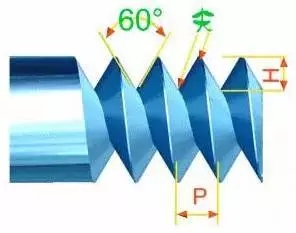

International Metric Thread System:

Thread used in national standard CNS of china. The tooth tip is flat, easy to turn, and the tooth bottom is arc shape, so as to increase the thread strength. The thread angle is 60 degrees, and the specification is expressed in M. Metric thread can be divided into coarse tooth and fine tooth two kinds. Express as M8x1.25. (M: code name, 8: nominal diameter, 1.25: pitch).

American Standard thread (American Standard Thread):

Both the top and the bottom of the thread are flat, and the strength is better. The thread angle is also 60 degrees, and the specifications are expressed in several teeth per inch. The thread can be divided into coarse tooth (NC); fine tooth (NF); extra fine tooth (NEF) three grade. Notation such as 1/2-10NC. (1/2: external diameter; 10: tooth per inch; NC code).

Unified standard thread (Unified Thread):

By the United States, the United Kingdom, Canada jointly formulated, for the current commonly used British thread. The thread angle is also 60 degrees, and the specifications are expressed in several teeth per inch. The thread can be divided into coarse tooth (UNC), fine tooth (UNF) and extra fine tooth (UNEF). Notation such as 1/2-10UNC. (1/2: external diameter; 10: tooth per inch; UNC code).

V thread (Sharp V Thread):

The top and root are sharp, weak, bad, not often used. The thread angle is 60 degrees.

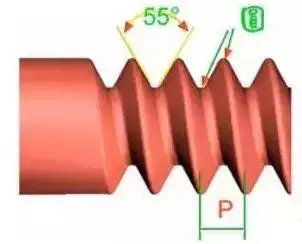

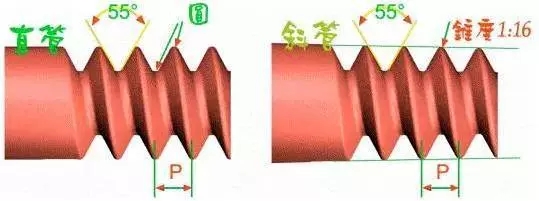

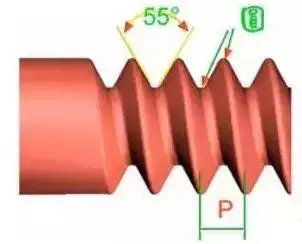

Whitworth Thread:

Threads used in British National standards. The thread angle is 55 degrees, indicating the symbol is “ W”. It is suitable for rolling process. Notation such as W1/2-10. (1/2: external diameter; 10: tooth per inch; W code).

Round thread (Knuckle Thread):

Standard thread for German DIN. It is suitable for the connection of bulb and rubber tube. The notation is “ Rd”.

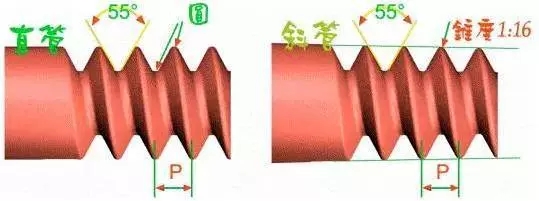

Pipe thread (Pipe Thread):

Threads used to prevent leakage are often used for gas or liquid pipe fittings. Thread angle is 55 degrees, can be divided into straight pipe thread code is ” P.S., N.P.S.” and inclined pipe thread code is “ N.P.T.” its taper is 1:16, that is, 3/4 inches per foot.

There are also industry professionals say: NPT is the United States standard 60 vertebral canal thread, North America standard, PT is 55 degrees taper pipe thread, belongs to the Hui thread, for Europe and the United Kingdom federal.

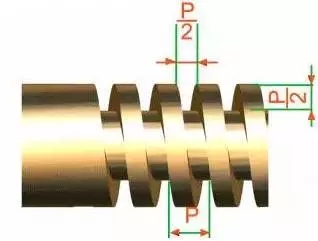

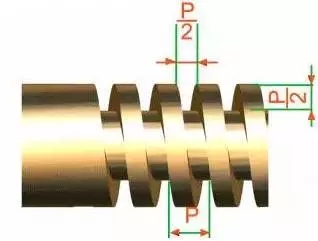

Fang Luowen (Square Thread):

The transmission efficiency is big, only inferior to the ball screw thread, but cannot adjust with the nut after wearing, is its shortcoming. Screw and crane thread for vise.

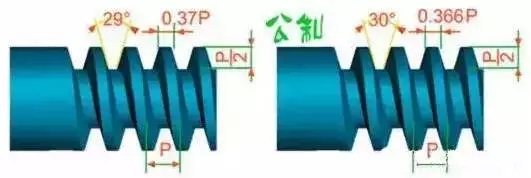

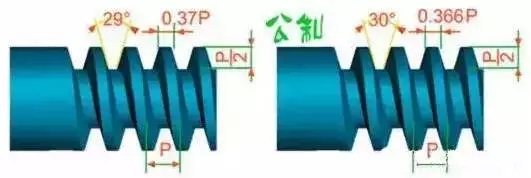

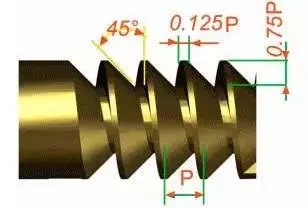

Trapezoidal thread (Trapezoidal Thread):

It's also called the love screw thread. The transmission efficiency is smaller than the square thread, but it can be adjusted by the nut after wearing. Metric thread angle is 30 degrees, British thread angle is 29 degrees. General guide screw used in lathe. The notation is “ Tr”.

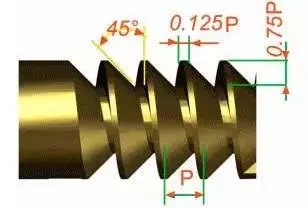

Saw tooth thread (Buttress Thread):

Also known as the trapezoid thread, only suitable for single direction transmission. Such as screw jack, compressor and so on. The notation is ” Bu”.

Inch thread:

The size of the British thread is usually expressed by the number of threads on the thread per inch, referred to as "the number of teeth per inch", which is exactly the reciprocal of the pitch. For example, every inch of 8 teeth thread, its pitch is 1/8 inch.

Seven friends DRY007 said: China's industrial standard is the Soviet Union 60 years ago, after the reference inch, forty years ago to thirty years ago to the national standard, American Standard, WTO and the rest of the world, and according to European standards, many European civil machinery now in our country, a lot of pitch tolerance is really very difficult to swap general.

According to the standard I know, there are four countries are not the same, the United States, Britain, Italy, Germany, the four countries of pitch, angle is different, good is now machine tool pitch is complete, can adjust to achieve accuracy. The trouble is that after the European machinery comes to China, the screw fittings are very troublesome.

Seven friends Iaminhere said: I contact the thread standards are also more. Often encountered in the measurement of unqualified, may be the factory processing of the lathe is too old, new machine tool price is very expensive, the production of gauge price is higher than other countriesNow the market is determined by your price.

Seven friendly mood 155 said: I work, English, beauty, European Union, Japan, the Soviet Union, worm anyway, multi line, involute, sealing, non sealing, serrated, trapezoidal, Archimedes line, the basic contact, why not a unified standard, after all countries want to do.

In this paper, more people in the industry are welcome to criticize and correct, so that more people have a comprehensive and detailed understanding of the thread of knowledge.

Source: chemical 707;

Official public micro signal