After China's entry into the WTO in 2001, the overall business income of the chemical industry has grown from 806 billion 900 million yuan to 91000 billion yuan in 2017, increased by 11 times, and first surpassed the United States in 2010, and established the status of the world's No. 1 chemical power. At the same time, in terms of revenue, the degree of industry agglomeration has been increasing. In 2002, the total business income of the top 500 Chinese chemical industry accounted for 21.6% of the total industry total. To 2016, this number has climbed to 54%. It is important to note that the number of enterprises in the top 500 groups accounts for only 2% of the industry.

Nevertheless, the global top 50 chemical industry is still rarely seen in China. China is already the largest manufacturing country in the world. In 2014, more than 220 kinds of industrial products in China ranked first in the world. The net export of manufacturing industry was the first in the world, and the manufacturing industry only added value to 20.8% in the world. If you sort global manufacturers of steel, cement, household appliances, cars, and mobile phones, there must be many Chinese companies on the top 50 list of the world's top. But there are 2 industries, if you list the world's top 50, there is only one Sinopec (and Taiwan plastic) in an industry, and the other is not in China. The first industry is the chemical industry, the second industry is the prescription drug industry.

The top 50 of the global chemical industry:

The games of Europe, America and Japan and Korea

In the 2017 world top 50 list of chemical products (GlobalTop50) published in July last year, China has only two companies, Sinopec and Taiwan plastic ($27 billion 100 million), BASF topped the list for $60 billion 700 million, Dow chemistry for 48 billion 200 million US $second, and Sinopec with third in $42 billion 800 million.

Throughout the list, the global chemical industry is still held by Europe and the United States and South Korea giant: the top 50 in Europe and the United States occupy 30 seats, Japan and South Korea have 8 and 4 enterprises, China and Thailand each have 2, and other emerging market countries such as India, Brazil, South Africa, Saudi Arabia and other 1 enterprises on the list.

There are two labels in the top 50 of the global chemical industry.

· one is diversification, that is, Integrated Company, such as BASF, Dow, MITSUBISHI chemistry, DuPont, LG chemistry and so on. These companies are involved in many kinds of business on the whole value chain, and more importantly, in the top 10 companies of these lists, in addition to DuPont, there is basically a large petrochemical plant;

· two is the simple Petrochemical Industries Co, that is, the general chemical products companies, such as Sinopec, chapeck, Taiwan plastic, Enshi, Exxon Mobil, lionde Basel and so on.

It is important to note that among the top 50 of the list, in addition to the United States, Europe and Japan (Canada is a potash, resource-based enterprise), the companies in other countries (Sinopec, Saudi Arabia, Brazil national chemical Braskem, South African Saudi Arabia, India trust industry, Thailand Indorama and PTT) all start with large petrochemical plants.

In addition to the above two types of enterprises, there is a professional company that can be counted on the list only by single business, such as liquid air (industrial gas), Lin De (industrial gas), erada (agro chemical), Xian Zhengda (agro chemical), sore (special chemicals), and timman (special chemicals). And all of them are concentrated in the United States, Western Europe and Japan, these companies produce specific products according to the specific needs of customers.

We will look at the chemical enterprises of the top 500 Chinese enterprises in 2016. Like the world's top 50, we do not consider BP, SHELL, TOTAL and other energy enterprises. We also eliminate the heavy enterprises, such as China oil, Shenhua, Henan, and flat coal, and other non chemical businesses. We found that the first group followed by the Sinopec is the comprehensive business enterprises of China chemical industry, Tianjin Bohua, Hubei, and cloud nature. Although they have a lot of revenue, they may be out of the C& EN statistical calibre and non chemical business, which can only be hovered outside the world's 50 top chemical industry. The second groups in the future are Wanda, Jingbo, Li Hua Yi, Hai Ke, Yu Huang and HSBC Shandong refining enterprises. It is not difficult to find that the first group, compared with BASF and Dow, who are sitting on the top of the list, most of them lack their own petrochemical plants. Most of the second groups do not have their own functional chemicals and materials.

We try to study the world's top 50 list of companies, to comb out the inevitable way for the rise of European and American Chemical giants and Japanese and Korean enterprises, in order to find the most likely part of the way to strike in Chinese enterprises that are outside the 50 strong threshold.

Technological innovation lasting 100 years and transformation after energy crisis

The history of chemical industry in Europe and America

1) &mdash in Germany; the birthplace of modern chemical industry

Modern chemical industry originates from organic chemicals, more specifically, synthetic dyes. Since William Perkin accidentally discovered aniline purple in 1856, new synthetic dyes have been found in France and Germany. In 1870s, German companies dominated the whole world's dye market.

Although all the initial inventions came from the chemical laboratory in University, the Private Companies soon founded its own R & D laboratory. In 1880s, some of the leading German companies invented several new dyes with their own R & D institutions. After more than ten years, the vast majority of synthetic dyes came from the company. Organizations, such inventions at this stage, often come from trial and error in the laboratory, and more empirical rather than academic research. After that, the work of the university laboratory is more directed towards the academic research on the properties and structures of the compounds, such as the discovery of the benzene ring structure in aniline, which lays a good theoretical basis for the invention of more different color reagents.

2) the age of technological change; — — the birth and growth of chemical enterprises.

In twentieth Century, with the rise of the automobile industry and modern agriculture and the huge petrochemical fuel and chemical fertilizer brought by itThe role of chemical industry in human economic and social development is becoming increasingly important. The modern chemical industry in Germany relies on the increasingly powerful R & D capability of universities / enterprises, and has realized the common progress of technological innovation and enterprise development by continuous innovation.

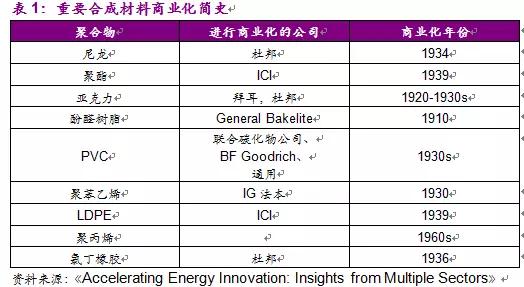

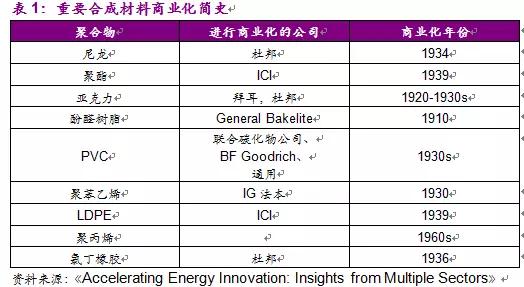

20 to 60s twentieth Century was the golden age of the innovation of the chemical industry. In this period, the other innovation power — — the United States joined the competition in the field of chemical industry with Germany, and the birth of DuPont and a number of great enterprises in Germany (BASF, Hearst, Bayer, etc.), DuPont, DuPont and Dow. Co - carbide and other companies are committed to major technological advances, which have brought unheard of synthetic materials such as Lu Lu, phenolic resin, nylon -6 and so on. With the explosive demand of the Second World War, the beginning of the polymer / petrochemical product revolution has been guided.

3) the &mdash — the division of chemicals and oil companies;

After the baptism of the two world wars, the chemical industry of the world developed rapidly under the impetus of the state's will. The chemical industry, which was an indispensable part of the operation of the war machine, still played a vital role in the post-war reconstruction. At this stage, the refining and chemical industry has already entered a mature period. After 1950s, the emergence of the engineering company and the progress of the later machine computing power make the time of the heavy chemical plant greatly shorten. The expansion and development of the oil refining and olefins industry has led mankind into the era of unprecedented stone oil and polymer materials.

At this stage, some chemical companies began to dabble in the field of refining and refining. On the other hand, some traditional oil companies, such as Exxon Mobil, SHELL, BP and Amoco, began to take advantage of the scale advantage of integrated operation and huge oil and gas reserves, trying to enter the field of final consumption in the field of professional chemicals. But they finally found that the effort was a little futile and powerless in the lack of an annual lack of technological accumulation, so they tended to extend their tentacles to polymer fields such as PE and PP. In the field of professional fine chemicals, BASF, DuPont, DuPont and Bayer still plow their own professional status. Of course, in the acquisition of oil and gas resources, these chemical companies are also lack of experience and advantages in the presence of traditional oil companies. They are only acquired by buying or building their own petrochemical equipment, so that they can be obtained. Take an integrated cost advantage.

In the half century after that, the traditional chemical giants found that relying solely on new molecules could not bring more growth to the company. These companies tried to grab extra value from existing assets, and in 70s and 80s, they passed. Changing sales and operating strategies to gain more market share, and in 90s, they began to gain scale and monopoly through unnaked integration and restructuring, or to form synergies and reduce product costs.

4) the shadow of survival under the oil crisis; — — the inevitability of chemical companies going to the petrochemical industry.

In the 50 years of twentieth Century, two times of oil crisis broke out successively. In addition, the tension of each oil supply and demand will lead to the soaring oil price, and both new energy and energy saving technology will become the hot spot of investment. 1973-1974, 1979-1983, and two oil crises have attracted the attention of the clean energy of alternative fossil fuels. High oil prices have forced a lot of money to go to clean energy such as solar and wind energy, but as the price of oil gradually suppressed, people quickly abandoned the economic alternative energy that was less than oil and once again in the next oil crisis.

In this cycle, traditional chemical companies in the West have realized that the ability to control upstream energy and raw materials has never been so important, although major chemical companies began to move into the petrochemical industry after World War II in order to obtain stable and cheap raw materials, but until the two oil crisis, BASF Bayer, Dow and others really began to make petrochemicals their core businesses on a large scale.

Basf, for example, began a new journey in the creation of chemicals in the 1950s, relying on the technology and market base of its synthetic dyes. In 50s, BASF began to open the overseas market through polystyrene resin products. Through joint ventures with British and American enterprises, BASF not only opened up the market of the United States, France, Brazil and Argentina, but also entered the field of making textile fiber products based on polymer.

Since the mid-1960s, BASF has entered Europe, North America, Asia-Pacific and Africa through mergers and acquisitions and joint ventures. In this process, the Basf Inc began to diversify, gradually active in the field of printing ink, insulating coatings and electrical materials, and laid the technical foundation for its later manufacture of automotive coatings and polishing materials.

But when it steadily expanded the field of special chemicals through technological innovation, the company never forgot the importance of the petrochemical plant to produce the basic chemicals — — in 1965, when the company set up a centennial celebration, Carl Wurster gave such comments: & ldquo; the founder of BASF was full from the beginning of the venture. It is aware that the success of the dyestuff and other high performance chemicals can be achieved only if the necessary raw materials and precursors are produced independently and the research and development activities are promoted and funded. So they created an excellent system that BASF used for 100 years and helped the company achieve great success. ”

In the course of the development of BASF in the second half of twentieth Century, it is particularly noteworthy that in the oil and economic crisis in 70s, the Basf Inc's development strategy was actively adjusted. By actively marching into the upstream petrochemical business, they took the integration as the source of constant chemical creation. Chemical enterprises are vulnerable to fluctuations in raw material prices. In order to reduce this risk, BASF began to take measures to connect the upstream and downstream business chain several decades ago. In 1969,Basf secured the supply of petrochemical raw materials by acquiring Wintershall, Germany's oldest oil and gas company.

A statement signed by the directors of the two companies said: “ the cooperation between the two companies and the business opportunities that the chemical industry needs refining in the field of raw materials will bring the greatest economic benefits. Combined with our financial advantages, we will seize the opportunities in the field of petroleum production and processing more rapidly and effectively. ” and in the aftermath of the 70s oil crisis, competitors fully realized the BASF's vertical integration advantage — — Wintershall supplied about 1/10 of the gas to BASF. By controlling the supply of raw materials, BASF can reduce the cost of raw materials. Since 2005, despite the sharp rise in oil prices, the impact of BASF has been far less than that of other chemical giants. In April 2006, BASF bought 35% of Russia's natural gas well. In addition, it holds a stake in an oil field in Western Siberia.

Under the integrated strategic framework, BASF has formed a global production network based on the basic chemicals produced by its upstream petrochemical plant, and develops the core business of intermediate chemicals and fine chemicals to the lower reaches of the downstream. By merging upstream and downstream enterprises to form a huge “ production chain ” and start to turn the target to the edge fields of chemistry and technology, chemistry and biological integration, such as biology and nanotechnology, trying to always be in the forefront of competitors.

The rise of Korean Chemical Enterprises

The power of the will of the state

South Korea's economic construction began in the 60s of last century. The situation in the South Korea was very similar to China after the reform and opening up. The energy endowment was innate and the human resources were rich. Based on this, the Korean government decided to concentrate on the development of light industries such as clothing, and took Japan as an example to learn from its road of economic construction from light industry. In 70s, in the tense confrontation with North Korea, the Korean government prompted the Korean enterprises to complete the “ from the light to heavy ” the Pu Zhengxi regime put forward the "heavy chemical industry plan" in 1973, and the petrochemical, steel, electronic, mechanical, metal and other 6 industries as strategic industries to be strongly supported. Today's big Korean enterprises such as SK, Samsung and Hyundai are all growing up in the Pu Zhengxi era.

After the Korean War, the path of China's industrial development is quite different from that of Korea. Under the international situation in the 1950s, China chose the road of plan-led and priority to heavy industry, which lasted until the reform and opening up in the late 1970s. In the meantime, the annual growth rate of light industry and heavy industry is 9% and 14% respectively. After the reform and opening up, China's light industry developed at a high speed. From 1979 to 1991, the average annual growth rate of light industry and heavy industry reversed, 14% and 10% respectively. We believe that the development path of domestic chemical private enterprises will be a reference for the development of Korean Chemical giants.

Although South Korea is deficient in raw materials, does not have the advantages of the Middle East, and does not have the huge consumer market like China, South Korea has developed into a powerful chemical power in the world. The export oriented strategy is an important reason. South Korea's chemical industry started in the 70s of last century. Due to the growth of the downstream product market in the petrochemical industry, the demand for the intermediate raw materials and basic raw materials is increasing in Korea. The Korean government has adopted a variety of preferential methods to motivate the private enterprises to turn to the heavy industry. Companies still focus on light industry because of lack of money and technology, such as the later chemical giant, LG, still engaged in toothpaste business (still in the domestic supermarket shelves) and SK for fiber services.

However, with the strong support of the government, with the liberalization of the Korean market and the privatization of the state-owned enterprises, Korean chemical enterprises have gradually realized the rise of the light industry transformation and heavy chemical industry, and began to develop rapidly in 1990s, and quickly become the largest ethylene producer in Asia after Japan.

LG chemical — — Korean chemical enterprises to diversify and heavy chemical transformation typical.

LG Chemistry ranks 12th among the top 50 chemical companies in the world in 2017. LG Chemistry is a diversified chemical enterprise with a revenue of 18.1 billion yuan in 2017. In 1947, the founder of lotus nunnum founded the loxi chemical industry society (now LG Chemistry), which originally produced cosmetics &ldquo and loxi cream ” later, in order to develop the plastic bottle cap that was not easily broken, LG group entered the plastic industry for the first time in South Korea. In 1954, it developed the earliest toothpaste in Korea and set up loxi grease in 1959. The production of soap and glycerin has laid a foundation for the chemical industry of one of the two pillars of its business activities. LG chemistry in this period was still focused on the field of daily chemicals. Since then, in 1967, LG group established the first private oil refinery in Hunan (now GS Caltex) and entered the field of basic raw materials industry, laying the foundation for its entry into the heavy chemical industry.

In 1970s, South Korea, through export led policy, promoted rapid economic development and entered the ranks of emerging industrial countries. LG chemistry also developed rapidly. In 1972, sales exceeded 1 billion 100 million won and exports reached $5 million 300 thousand. Through the early accumulation of capital in chemical light industry products, LG chemistry completed the first and second expansion projects of Hunan oil refining (now GS Caltex). The factory started to increase its production capacity to 3 times in only 3 years. The petrochemical plant provided a stable, cost advantageous basic chemical material for LG, thus the rapid rise of LG chemistry in the later period. It has laid the foundation for development.

In 1980s, under the impetus of the Korean government, Korean enterprises gradually completed the transformation to heavy chemical industry. In the field of chemistry and energy, LG chemistry is in line with the development strategy of the western counterparts. After the 1983 energy crisis, the petrochemical industry is the focus of development and is based on the scale of the petrochemical plant.Advantages, deepening the development of plastic, daily necessities, precision chemistry and other existing fields, and re entering the cosmetic industry, expanding the synthetic industry, entering the field of pharmaceutical products, realizing the diversification of the cause of the cause, and through the active overseas investment, began to step into the ranks of cross country enterprises.

The rule subversive — — the impact from emerging market enterprises.

In the past few decades, Europe, America and Japan, Japan and South Korea, Japan and South Korea, the old brand of chemical giants are very consistent: Based on solid technology accumulation and asset base, committed to profit appreciation, and based on the local market, in the rapid economic growth of emerging market countries to find opportunities. With the development and expansion of enterprises from oil and gas producing countries (Saudi Arabia, Brazil, etc.) and emerging market countries (China, India, Brazil and so on), the competition pattern of the global chemical industry has changed greatly. These emerging enterprises compete according to different rules. Compared with the old companies in Europe and the United States and Japan, they no longer need a hundred years of technological innovation to practice their own industry status, and have the hope that in the next few decades, they will become the subversive of the industry.

These companies have taken two different paths: enterprises from oil and gas producers have control of the dominant materials in the high oil price stage, and they pay attention to the monetization of resources, while companies from emerging market countries have the ability to give priority to the most dynamic consumer market, and they benefit from the rapid economic growth of the regions in which they are located. Development. The former example is Sha Bi Ke, a typical example of the latter is Sinopec and India faithfulness. They gained considerable sales through different competition rules and succeeded in the top 50. Another point worth noting is that the lowest threshold for entering the top 50 in 2017 is US $5 billion 900 million. Although the relationship between sales volume and profit is not entirely positive, but only with a certain volume of income to support the level of profit.

But relying solely on huge sales volume is not enough to achieve a great enterprise, the embodiment of competitiveness is omni-directional. In this respect, Korean chemical enterprises are the example &mdash of the new market national chemical enterprises; they have begun to build their own in an age when they get out of the competitive position with the cost and market advantage. Technological innovation, marketing management and other capabilities, in order to equal with the old European and American enterprises.

· SK energy company is vigorously reducing costs, changing raw material models and optimizing process.

Middot; Samsung Dodal Petrochemical is investing in energy-saving projects while strengthening its position as a major producer of polypropylene, styrene and p-xylene.

· LG Chemicals is fast growing in rechargeable batteries and electronic materials, while Hanhua Chemicals is targeting the solar cell business.

Through the above research

It is not difficult for us to draw the following conclusions

First, the chasing strategy of the chemical enterprises in developing countries should start from large petrochemical plants, make themselves bigger and maintain the average profit of the enterprise cycle at billions of yuan, so as to have the strength to gradually develop to the high and sharp special materials.

Second, for developing countries, it is really great to start to catch up with special chemicals as the main industry. Because many of the downstream supporting enterprises of advanced materials are in developed countries, it is very difficult for you to cut in, but perhaps China will be a special case.

At present, China's large-scale chemical enterprises are implementing these two approaches.

The first road is the frontline representatives of Wanhua chemical, Hengli stock and Rongsheng petrochemical. Hengyi petrochemical, satellite petrochemical and Donghua energy are the second line enterprises. They are the core way to move the large petrochemical plant to the pace of progress. Even with the success of Wanhua in MDI, they are further moving towards large-scale international chemical enterprises. This route is still chosen, from which we can see the difficulty of breaking through the ceiling.

At present, the second road should take Kang Dexin as the first line (the core is the optical film and carbon fiber as a breakthrough), the typical road resistance and long, only adhere to the forward, but the market has also given a very high premium.

The first way is to take heavy assets as a prerequisite for the development of the enterprise, which is contrary to the current market preference shares, but this is the only way for the rise of Chinese chemical enterprises, whether you like it or not.

Source: Everbright Securities - Everbright petro chemical Qiu Xiaofeng team