The development history, existing problems and shortcomings of the pressure vessel steel in China are expounded, and the gap and reasons for the steel for pressure vessel are found out, and some suggestions are put forward for the research and development, production, sale and use of the steel for pressure vessel in our country.

Key words for high performance market sales of pressure vessels

The production history and present situation of pressure vessel steel

During the period from 1950s to 60s, the pressure vessel steel began to develop to high strength, and the yield strength of 490 MPa grade steel was developed in many countries. A series of steel grades yielding strength of 690 MPa have been developed and used in the United States, Germany and Japan. Japan has also developed steel grades with yield strength of 890 MPa. China's pressure vessel steel has been lagging behind for a long time. By the early 80s, China has developed 20R, 22R, 16MnR, 1sMnVR, 1sMnVNbR and 18MnMoNbR steels for low alloy and high strength pressure vessel steels. 16MnDR, 09Mn2VDR and 09MnTiCuReDR steels have been developed in low temperature steels. However, the toughness indexes of these steels are very low and unstable, the welding performance is poor and the level of the physical and toughness index is not high, which can not meet the requirements of the high parameter large pressure vessel. In order to change this backward situation, we have also begun to develop and develop domestic high performance pressure vessel steel, and have developed a new generation of low temperature welding crack sensitive steel, high strength steel for large line energy welding, and also developed high performance low temperature steel, medium temperature hydrogen resistant steel and low alloy high strength steel, total of more than 10 new steels. Species. From the results of industrial experiments, the technical index and toughness index of these domestic steel grades have reached or surpassed that of similar foreign steel grades.

At present, more than 3000 pressure vessel manufacturing enterprises in China need 1 million T for pressure vessel steel, of which low alloy, high strength steel 45 500 thousand T, low temperature steel 5 60 thousand T, medium temperature steel and forgings about 30 thousand T. These high technology and high quality steels are still scarce in the domestic market, and some specifications can not be produced and still rely on imports. For example, the quenched and tempered high strength steel, medium temperature hydrogen resistant steel with a thickness of more than 100 mm, and low temperature steel at 71 to 196 degrees per year need to import thousands of tons.

Pressure vessel manufacturing industry is a more special industry. Its products are mainly pressure tank, reaction preparation and pressure package, which are either large or small and bear certain pressure. According to the use pressure, the pressure is 0.1 MPaGp ≤ 1.6 MPa is a low pressure vessel; the pressure is 1.6 MPa≤ P < 10MPa is medium pressure vessel; the pressure is 10 MPaC P ≤ p≤ the 100 MPa is high pressure vessel; the pressure is the ultra high pressure vessel. Especially under the action of high temperature and high pressure medium, the demand for its products is even higher. From the international point of view, the American Association of Mechanical Engineers (ASME) has formulated the steel technical standard for pressure vessels and the SPU24-80 Series in Japan; the Standardization Committee of the pressure vessels in our country also published the regulations on the design of the pressure vessel in the steel petrochemical industry in 1988. In 1999, the existing material inspection standards and technical conditions were made. Big changes. International standard IS09002 also puts forward requirements for the technical conditions of 3 1 100 mm bearing steel plate and the special properties of high temperature and low temperature vessel steels. This will promote the development of pressure vessel steel plate manufacturing technology, and constantly improve the quality of material to meet production needs.

Two. Analysis of steel demand for large pressure vessel manufacturers in China

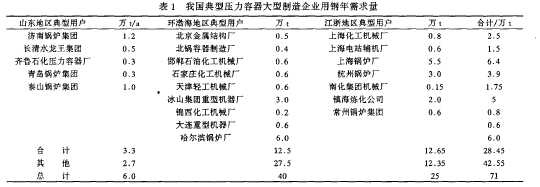

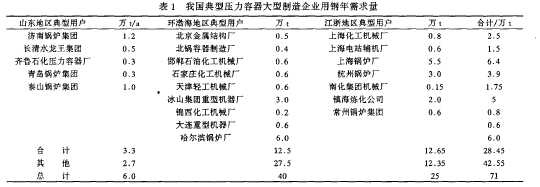

Because of the large number of manufacturers and wide distribution of the pressure vessel manufacturing industry in China, about 65% of the manufacturers are concentrated in the coastal and eastern regions of the Yangtze River, with more than 83.61% of the total material used. More influential pressure vessel manufacturers include Shang pan, haha, hang Guo and Zhenhai Refinery (Table 1).

Through the field investigation of pressure vessel steel in different areas, it is found that some enterprises have poor economic benefits and the annual benefits of good enterprises are only 200 and 40 million yuan; poor enterprises can only maintain normal production. In a word, the manufacturing industry of pressure vessels is difficult.

It is understood that the State Ministry of labor will focus on the three types of pressure vessels and a grade a boiler manufacturers to support and exchange certificates. If this work is successfully implemented in the near future, the benefits of the pressure vessel manufacturing industry will be improved.

Analysis of production of pressure vessel steel for main steel works in China in three and 1998 --1999

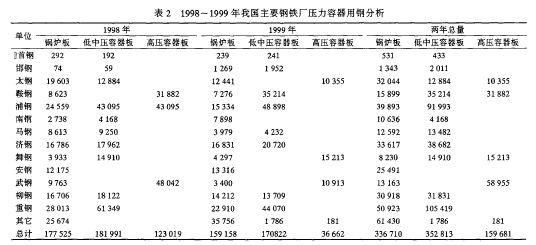

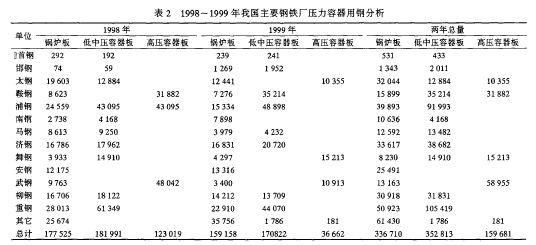

From table 2, we can see that during the period of 1998 and 1999, the enterprises with the largest absolute production of boiler steel were higang, Pu steel, Jigang, Taiyuan Steel and Liuzhou Steel. The enterprises with the largest absolute production of low medium pressure vessel steel were heavy steel, Pu steel, Jigang, Anshan Iron and steel company, and Wuhan Iron and steel company with the absolute production of high pressure vessel steel has Wuhan Iron and steel company. Anshan Iron and steel, Wugang, Taiyuan Steel. Because most of the production enterprises of pressure vessel steel in our country can only produce low medium pressure vessel plate and boiler plate, the overall quality and price competition in the low level are still in the low level. Throughout the factories of Chongqing Iron and steel, Pu steel, Wuhan Iron and steel, Anshan Iron and steel, Wugang and Taisteel, there are iron water pretreatment technology, electric furnace steelmaking, furnace refining technology and high purity steel smelting technology, thus ensuring the purity of steel and uniformity of the alloy composition, and adopting the production technology of defect free and thick continuous casting billet, and the application is advanced in the field of rolling. The rolling technology is improved to ensure the comprehensive performance of the product, and the existing heat treatment equipment can be improved to further improve the quality of the product in order to meet the needs of the national economic development. However, there is still a gap between these steel mills and foreign advanced enterprises, mainly as follows: (1) the qualification rate of steel plate flaw detection in high grade pressure vessels is low; (2) low welding crack sensitivity container steel development is slow; (3) the content of sulfur and phosphorus is high; (4) Akv, the value is low and the toughness is poor; 5. The surface quality of steel is poor, and there is a strip oxidation. Iron pits and star cracks; large size and wide steel plates can not be produced.

Four. IDevelopment plan and sales suggestion for domestic pressure vessel steel

(1) at present, the standard of materials used in pressure vessel manufacturing industry is not high in China. Some containers have little pressure, and even use ordinary carbon plates instead of pressure vessels. In addition, at present, the efficiency of the pressure vessel manufacturing enterprises is poor. In order to reduce the production cost, the cheap universal carbon and low alloy plates are used within the standard range of the state. At the same time, as the national labor safety supervision department has not been able to revise the standard of pressure vessel material in recent years, some pressure vessel manufacturing industries are still in low water. Run smoothly.

In view of the present reality of the production of pressure vessel manufacturing industry, it is suggested that some enterprises with small force and energy parameters of medium plate mill and not perfect refining equipment should focus on the production of general low medium pressure vessel steel to meet the needs of market development, and the rolling technology of heavy steel, Wuhan Iron and steel, Pu steel, Wugang and so on is better and higher refining level, Enterprises with better heat treatment level should focus on the development and production of high performance, large parameter pressure vessel steel and low temperature, high temperature steel to reduce the import of this kind of steel every year.

(2) from the regional market, Chongqing Iron and steel is located in the southwest. It is also the earliest manufacturer of steel plate series of low, medium and high temperature pressure vessel in China. The product quality is stable. It is also the first domestic user exemption product approved by the Safety Supervision Bureau of the Ministry of labor boiler and pressure vessel. Its reputation is good, its products are all over the north and south of the river; WISCO is located in the country Central and southern China, with advantageous geographical location and convenient transportation, is an old industrial base in China and Hubei. The pressure vessel manufacturing industry is relatively developed. In recent years, because of the breakthrough in the steel production of Wugang in boiler and pressure vessel, the product gradually radiated around and promised to be in the national uniform price. Heat treatment equipment, thickness 8 150mm thick plate to ensure mechanical properties, its products have been accepted by the user, but because of its high cost, it affects market share; the low and medium pressure vessel steel produced in Jigang has a high market share in the surrounding area. In 2001, with the L3500 mm, rolling pressure of 70 MN plate mill The installation of the two phase project will take place. The start of the 120 t converter + refining and efficient slab continuous casting project will have a breakthrough in the production of high performance pressure vessel steel.

(3) pay attention to the international market, readjust the product structure, and do well in deep processing and supporting work. To do a good job of market demand research for pressure vessel steel, always pay attention to the demand change of international and domestic pressure vessel steel and the use of new steel, readjust the product structure at any time, so that the research and development is practical, the product has a lodging, and the international market is quickly connected. At the same time, we should do well in the matching of pressure vessel tubes, pressure bags and deep processing of stamping heads to meet the needs of users at different levels.

(4) establish efficient regional markets according to regional economic advantages. At present, there are 7~8 manufacturers for mass production of steel for pressure vessels, and their products can basically meet the requirements of general users. Some large parameter pressure vessel steel can be produced only by a small number of enterprises such as Wuhan steel, Pu steel, Anshan steel, heavy steel and so on. It is still difficult to meet the needs of the high pressure vessel steel for the eastern developed and middle south areas. Therefore, it is suggested that in the East, Jigang should be developed and Liuzhou Iron and steel company should be developed as its industrial supplement, so as to reduce the increase of steel price caused by high transportation cost, it is very important to establish an efficient regional market.

(5) strive to develop two international and domestic markets and cultivate marketable products. For the urgent need of new steel for international and domestic pressure vessel steel, the joint research and development of the steel plant and pressure vessel manufacturer should be adopted by the pressure vessel manufacturer to provide the pilot site, which integrates production, research and marketing. Only in this way can the distance between the steel plant and the user be closer, and the downstream industry will be more willing to accept the new research and development. The product is gradually promoted, which is more conducive to the technical progress of pressure vessel steel.

(6) strengthen the sales service system, strengthen the management of end-users, and carry out user satisfaction engineering activities. Strengthen the tracking service of pressure vessel steel terminal users, establish and improve the file system of pre sale, sale and after sale of pressure vessel steel, properly handle the relationship between the middleman and the end user, standardize the operation behavior of the middleman, avoid its profit, and make the downstream industry as possible as possible, and actively carry out the user satisfaction live. Move, listen to the problems and shortcomings of the user in the process of manufacturing or use; objectively evaluate the user's contribution rate, and then optimize the product structure and select the strong end users.