First, a summary of packing tower

(a) slot liquid distributor (gravity type liquid distributor)

1, single slot liquid distributor

Single slot liquid distributor or through the distributor, the structure is compact, connected between the groove and the groove, can keep all the slots at the same level level, so it is easy to achieve uniform liquid distribution. Commonly used in size less than 1m in the tower.

The 2 and two level trough type liquid distributor

Two slot liquid distributor by main channel (a slot) and groove (two slots), placed in the main tank. To flow liquid directly into the first slot, and then to the proportion of distribution to each of the two slot.

Advantage:

(1) the structure is simple and easy to assemble from the air into the tower;

(2) the air passage is uniform and the free section area is large.

Disadvantages: the space is larger, and the level of each two tank is not easy to reach a complete agreement.

Applicable occasions: generally used for tower diameter greater than 1m of the tower.

(two) the liquid collector and distributor

1, block type liquid collector

Cover plate liquid collector is an internal common collection device, liquid collection and liquid phase extraction. Generally placed under the packing layer, the liquid can be collected. The upper edge of the flange for collector is fixed between the upper flange of a cylinder body, packing down the liquid guiding groove in the cover plate on the back into the liquid collecting plate in the following. The tower diameter is large, but also is provided with an annular groove around.

Advantages: the liquid collection is complete, at the same time, the gas phase resistance is very small.

Disadvantages: single liquid collecting plate arranged, inclined plate gas will guide the tower wall, the gas distribution is uneven; the annular groove is occupied large section, resulting in local resistance, increase the pressure drop of the whole column.

Applications: General for small diameter tower in flange connection, the use of the multi tower section when used in conjunction with the trough type liquid distributor.

2, split type liquid collector

Split type liquid collector comprises a single stream and dual flow, the cover plate is connected with the liquid plate fixed on the welding ring groove in the tower body, in order to facilitate the entry from the manhole cover plate three, liquid film is integrated into the tower after assembly. The tower diameter larger than 2.5m or large amount of liquid can be made into a double flow tower type structure.

3, lift pipe type liquid collector

The structure of lift pipe type liquid collector is similar to the trough pan liquid gas distributor is arranged on the upper end of the riser, a liquid blocking plate, to prevent the liquid from the trachea or fall. For all the liquid discharging liquid hole collector uneasy arrangement, on the part of data collector is to arrange the liquid distributing hole.

Advantages: compared with the cover plate type liquid collector, the resistance is bigger, but the uniformity of the gas distribution is better.

4, swash plate liquid collector and distributor

Swash plate type liquid collector and distributor is the slot liquid distributor and liquid collector combination, in addition to the advantages of the slot liquid distributor, the distribution for collecting the liquid, but also can save the space in the tower, very suitable for the small diameter tower.

Advantage:

(1) the position is low. Usually by the slot liquid distributor and a liquid collecting cover plate liquid collector composed of redistributor, occupying height is about 1.2-1.6m, and the swash plate liquid collector and distributor for the lowest height is 0.5m, greatly reducing the height of the tower;

(2) the free cutting area is large and the gas phase resistance is small;

(3) the installation is convenient and the cost is low;

(4) the linear distribution of liquid can be realized, which is especially suitable for occasions where the distribution points are required.

5, the combined liquid collector and distributor

The liquid collector and conventional liquid distributor together constitute the combined liquid collector and distributor, such as combination of cover plate liquid distributor and slot liquid distributor, can be used for regular packing or random packing tower. After the combination of a higher level, the overall height of the tower has also increased.

Disc type liquid distributor, liquid distributor, injection type liquid distributor, packing support, demister.

Two, tray type summary

(a) tray

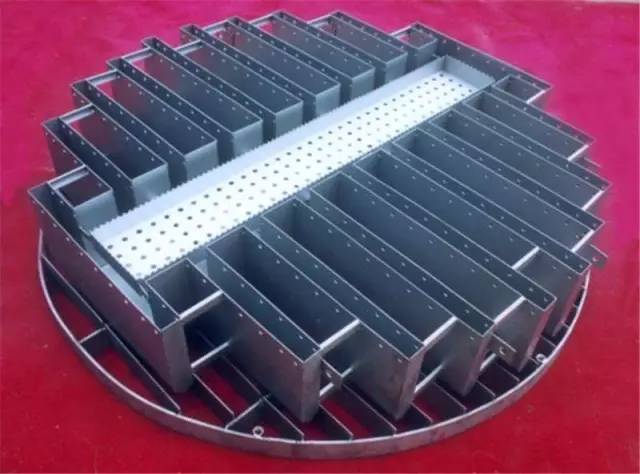

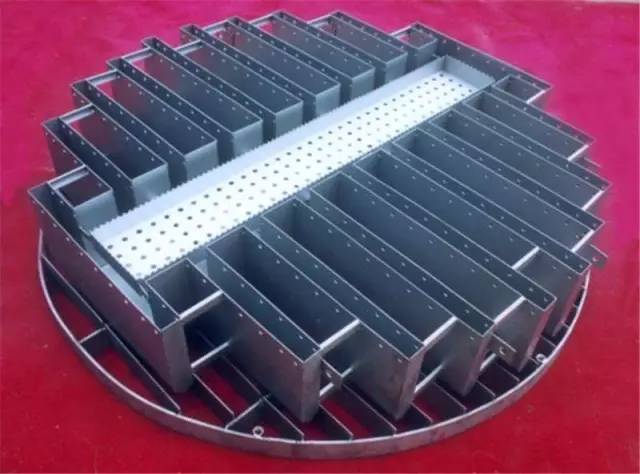

A tray tray is very early, 1950s to sieve the industrial simulation and study, to open a lot of small diameter holes in the trays, when operating gas at high speed through the hole up through the downcomer liquid flow to the next stage, the rising gas to liquid layer on the tray into the foam layer strongly turbulent.

Advantage:

(1) the structure is simple, easy to process, the cost is about 80% of the floating valve tower, about 60% of the bubble cap tower;

(2) the amount of treatment is larger, compared with the bubble cap tower 10%-15%;

(3) tray with high efficiency, a bubble column increases 15%;

(4) lower pressure drop than the bubble 30% low tower.

Disadvantages: installation level on the tray require a higher degree of flexibility, small, easy to plug the hole plate.

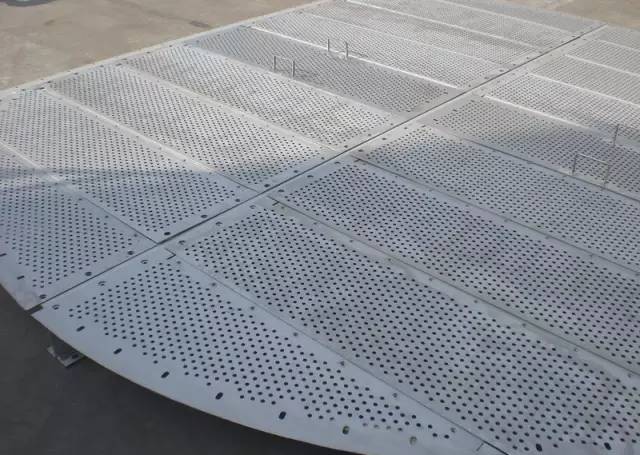

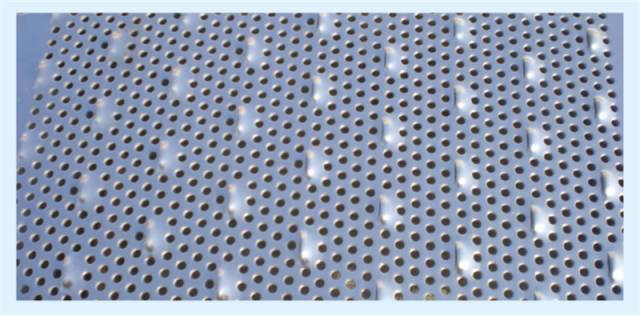

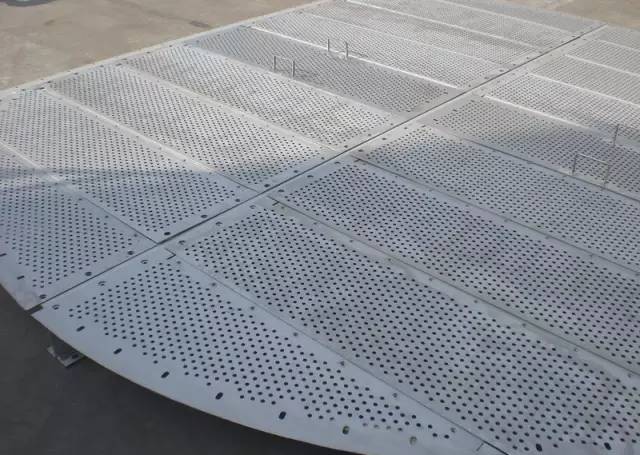

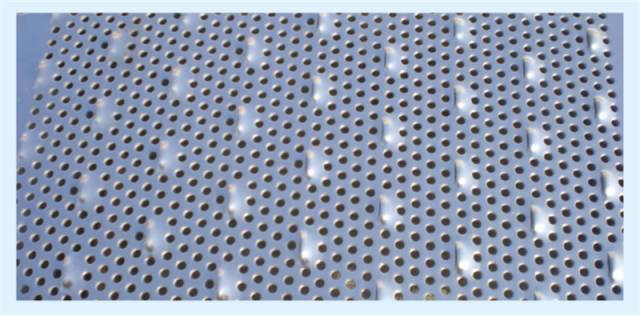

(two) guided sieve tray

The guide tray is to increase the number of guide hole based on the sieve tray, which can effectively improve the performance of the sieve tray.

Advantage:

(1) the gradient of the liquid level is small, and the bubble is uniform;

(2) the liquid reaction is small, and the plate pressure is reduced;

(3) entrainment is small, and the amount of liquid leakage is small;

(4) strong anti clogging ability;

(5) compared with the ordinary sieve tray efficiency can be increased by more than 10%~30%, the operating flexibility can be increased by 10% to 20%.

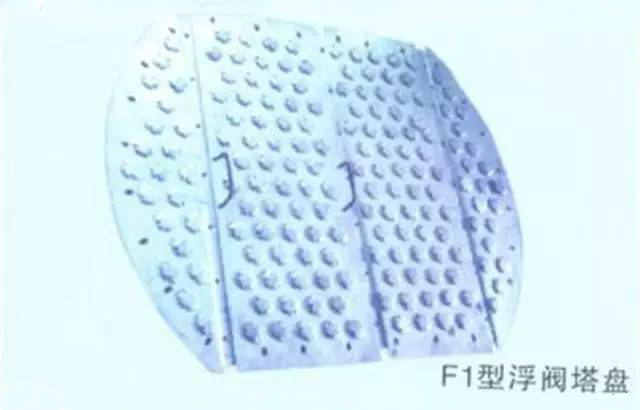

(three) float valve tray

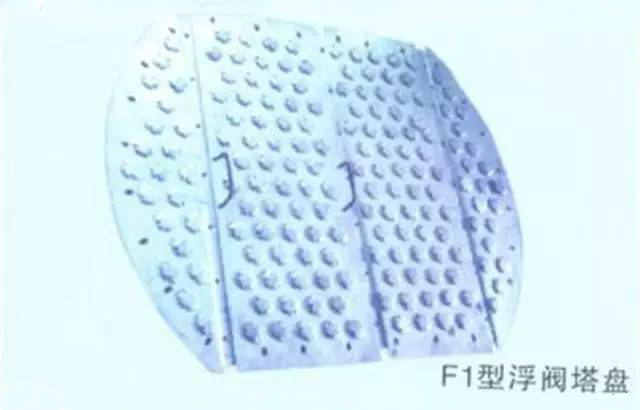

1, F1 type float valve tray

Since 1950s, the floating valve tower has been widely used in industrial production, in order to complete the pressure, atmospheric pressure, distillation, absorption, desorption and other operations. Large floating valve tower tower diameter is 10m, there are hundreds of pieces of tray. When the steam from the valve hole up, open top valve, through the annular gap in the horizontal direction after blowing liquid layer and the formation of foam.

Advantage:

(1) a larger production capacity than captray can be increased by 20%~40%;

(2) flexible operation. Float valve can be freely lifted in a certain range to adapt to the change of gas flow, and thus can maintain high efficiency in a wide range;

(3) separation efficiency is high;

(4) tray pressure drop is small.

Disadvantages: the valve is easy to fall off, card dead.

2, F4 type float valve tray

F4 type float valve tray is a common circular float valve tray, the valve hole is a Venturi type, less resistance, suitable for vacuum system.

Advantage:

(1) greater production capacity;

(2) flexible operation;

(3) separation efficiency is high;

(4) tray pressure drop is small.

Disadvantages: the valve is easy to fall off, card dead.

3, guide trapezoidal valve tray

Directed trapezoidal valve with guide trapezoidal valve tray, one or two float valve guide hole, the guide hole and the opening direction of the tower plate flow direction. Directed trapezoidal valve are arranged at both ends of the valve leg, outflow from both sides of float valve in operation in the body, the liquid flow direction perpendicular to the direction of flow of the gas on the tower plate. Directed trapezoidal valve having two guide holes, can be properly arranged in a tower plate on both sides of the bow area, in order to speed up the flow of liquid in the region, thereby eliminating liquid stagnant regions on the tray.

Advantage:

(1) processing capacity than the tongue type tray and tray smaller than large captray;

(2) flexible operation;

(3) larger than the dry plate pressure drop, tongue type tray, than captray drop and tray level gradient;

(4) smaller entrainment;

(5) the valve open and flexible, not easy to fall off and die, jam.

Other types of tray, including solid tongue tray and bubble cap tray, floating tongue tray, sieve tray, vertical cross flow tray (without overflow device).

Process equipment network finishing release, reproduced please indicate the source.