Heat exchanger is a kind of static equipment used for heat transfer in chemical production. The heat transfer between two different mediums in the heat exchanger makes the larger temperature difference tend to decrease. Heat exchanger is often used as heater, cooler and evaporator in chemical production. The heat exchanger can be made of metal materials (such as copper, aluminum, carbon steel, stainless steel, etc.), also can be non-metallic materials (such as graphite, glass, plastics, ceramics, etc.). The chemical production of heat exchangers used a tubular heat exchanger, heat exchanger, tube heat exchanger, heat exchangers, corrugated plate heat exchanger, spiral heat exchanger, finned heat exchanger, graphite heat exchanger and new type heat exchanger heat pipe etc.. Many types of heat exchangers, this paper mainly introduces the repair method structure of tubular heat exchanger and the common fault.

A tubular heat exchanger installation knowledge

The tubular heat exchanger is the chemical production used as a heat exchanger widely, it has the advantages of simple structure, high heat efficiency, strong adaptability (in high or low temperature, high pressure or low pressure conditions can be used).

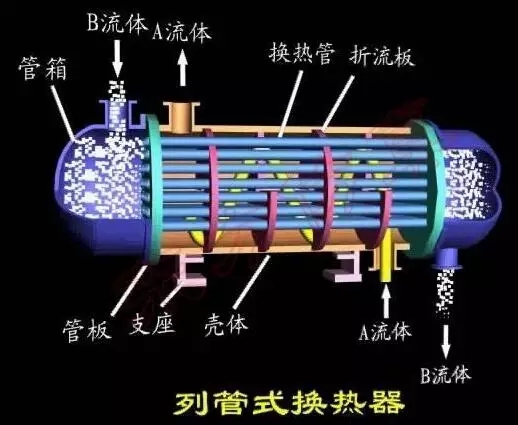

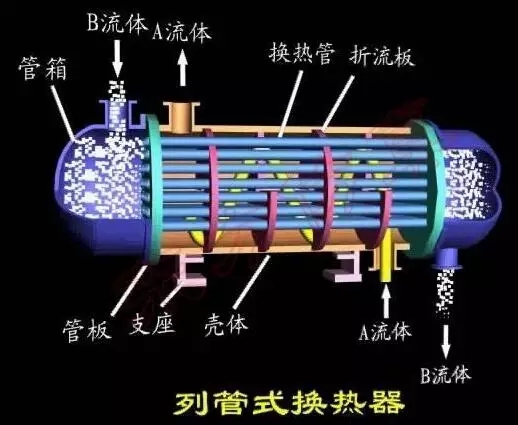

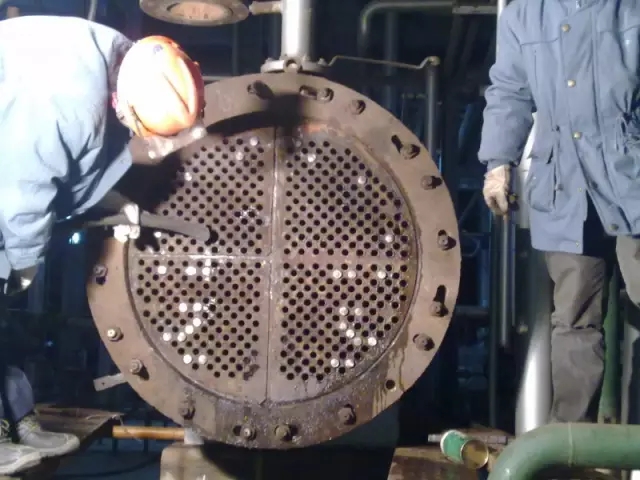

The main structure of tubular heat exchanger is in a cylindrical shell, which is composed of many parallel arrangement of tube bundle.

The two ends of the shell are provided with flanges, and the end cover is connected with the shell by a bolt. The shell and the end cover are respectively provided with two inlet and outlet small flanges of the medium, which is convenient for the corresponding pipeline connection. Commonly used in the tubular heat exchanger has a fixed tube plate, floating head type chemical production, U shaped tube and shell has several thermal compensation function.

Main structure of fixed tube plate shell heat exchanger:

Head; heat exchange tube; baffle plate; shell; support

The tube plate (also known as the flower board) and the two ends of the shell form a non detachable fixed connection. The two ends of the pipe are connected with the tube plate by the method of expansion welding, in order to change the flow direction of the medium between the pipes and improve the heat exchange efficiency, a plurality of baffle plates are arranged on the inner wall of the casing.

The end cover at both ends is connected with the shell through a flange. There are two kinds of different media in the pipe and pipe. In order to improve the efficiency of heat exchanger, sometimes set partition in head, forming a fluid distribution chamber, which constitute the so-called double tube tubular heat exchanger or four tubular heat exchanger.

1, preparation before installation

To do well the preparation work before the installation of the heat exchanger, the installation work can be carried out smoothly.

(1) site preparation for construction

According to the site layout construction, the actual investigation of the scene of other aspects of measurements to determine the transport routes, truck parking location, location and environment affect the transportation and installation of equipment, cooperation with others to meet the lifting requirements of working conditions. To clear the road of transportation, it is necessary to ensure that the road is smooth and stable, so that the vehicle can pass smoothly and safely. Installation width should meet the installation requirements.

(2) acceptance of heat exchanger

Safety equipment drawings carefully check, including the type of equipment, quality, size, technical characteristics of nozzle orientation. Refer to the technical documents such as factory certificate, specification, quality assurance, etc.. Check whether the equipment is damaged, missing parts (including iron, bolts, gaskets, accessories, etc.). Check and record.

(3) acceptance of foundation

The heat exchanger must be carefully checked and accepted before installation. The basic construction unit shall submit the certificate of quality, survey record and relevant construction technical data. On the basis of the obvious elevation lines and vertical and horizontal lines, the foundation should be cleaned, if the defects should be processed.

(4) preparation for hoisting

Lifting department should be ready for all machines such as cranes, rigging, pole, wire rope, pulley, chain and ring card, and according to the safety regulations seriously carry out inspection work. The large heat exchanger, because of large diameter, heating pipe, lifting the weight lifting, thus binding part should be selected in the reinforcing plate shell bearing, and wood in both sides of the housing for the protection of housing, so as to avoid lifting wire rope in the shell is collapsing deformation.

(5) prepare construction scheme

In order to make the installation work in an orderly manner, should be prepared before the installation of construction scheme, construction scheme should include the preparation, compilation basis, project survey, construction preparation, construction methods and measures, technical measures and technical requirements, construction equipment, construction materials, construction personnel allocation, construction schedule etc..

2, the installation of heat exchanger

The installation is generally carried out in the following order and requirements.

1 check the heat exchanger parts of the size of the deviation is in line with the requirements of the standard, the national standard GB151 standard for the heat exchanger: heat exchanger of the training data.

2) on the basis of the movable support side should be pre embedded anchor bolts slide, on both sides of the pad iron. Equipment and equipment and tilting pad iron base plate welding work, but not with the flat iron pad or slide welded, and iron pad must be smooth and flat, to ensure that activities support free expansion.

3) anchor bolt support activities should be installed two nut tightening, the gap should be left 1~3MM nut and the bottom plate, the bottom plate can slide freely.

4) the allowable deviation of heat exchanger installation shall meet the following requirements:

A. elevation ≤ 3MM

B. vertical (vertical) ≤ 1/1000 and not more than 5MM, the level of ≤ 1/1000 (horizontal) and not more than 5MM C &le 5MM center displacement.

5, the pipeline connected with the heat exchanger, in order to avoid the strong assembly, should be in the state of no force connection, and should not prevent the heat expansion of the heat exchanger.

3, pressure test

The pressure test of the heat exchanger (with fixed tube plate as an example), different types of heat exchangers, the test is somewhat different.

First, remove the head of the heat exchanger, the shell of the hydraulic pressure (commonly used water) test. When the test pressure, in addition to check the heat exchanger shell, should be focused on the heat exchanger tube and tube plate connection (hereinafter referred to as the joint) to check whether or not the joints welded joints. If a small number of joints have leakage, you can do a good job of marking, after the release of pressure to re expansion welding, and then do pressureForce test until qualified. After passing the test pressure of the pipe, the head of the gasket is added, and then the pipe pressure test is carried out.

4, annex installation

The installation is heat exchanger, can be fixed after leveling, pipes, valves and safety accessories installation. The installation method can refer to the installation of the pipeline.

The maintenance of heat exchanger tube two.

The tubular heat exchanger in the use process, the most prone to failure is the pipe parts. Medium of pipe flushing, etc. may cause corrosion damage of the pipe, so the regular inspection of heat exchanger, in order to detect faults, and take corresponding measures to repair.

The most common fault of tubular heat exchanger has wall fouling, pipe leakage and vibration etc..

Aspect 01: remove wall fouling

Inside and outside wall heat exchanger tubes in the tube, because the media often exist, it is easy to form a layer of fouling. The formation of fouling will directly reduce the efficiency of the heat exchanger, so it should be timely cleared. The removal method of pipe wall fouling, can be repaired by mechanical method and chemical cleaning method.

Aspect 02: leakage repair

Tubular heat exchanger tube bundle is composed of many tubes arranged, mainly due to erosion corrosion medium pipe leakage. Inspection of pipe leaks must be done prior to repair.

The method is commonly used in pipe leak check: setting the sampling orifice in the low pressure cooling water outlet end, on a regular basis cooling water sample test. If the cooling water contains the components of the cooling medium, it shows that there is a leak in the tube bundle. And then use the pressure test method to check the tube which leaks.

When the examination, the first end and blind plate bundle, and bundle into the pool, and then use the pressure of not more than 1× 100000Pa of the compressed air, separately into each test tube.

When the compressed air enters a nozzle, if the bubbles in the pool, then this game has a leak, can make the marking in the nozzle. This method is used to inspect all the pipes, and according to the damage of the pipe, different repair methods are used.

1, a small amount of pipe leakage repair methods

If only one or a plurality of tubes in tube leakage, taking into account the heat efficiency is not affected in the heat exchanger, can adopt the method of blocking leakage pipe repair. Each matter of both ends of the pipe with a tapered metal plug, the damaged pipe not blocked.

As to 3-5 DEG taper conical metal is appropriate, plug big end diameter should be slightly larger than the diameter of expansion pipe part.

2, the repair method for more pipe leakage

If the leakage of the pipe is more, the use of blocking the method of repair, will greatly reduce the heat exchanger efficiency (usually the number of tubes can not be more than 10%). At this time, the method of replacing the pipe is adopted:

(1) removal of the leaking pipe

The removal of a pipe is the process of drawing the tube out of the tube plate. Remove the tube, using the method of drilling and reaming for nonferrous metal pipe wall, the pipe can also for chipping method to remove with a sharp chisel.

Methods using drilling reaming or dismantling pipe, drill or reamer diameter should be equal to the inner diameter of the tube plate hole.

Drilling and reaming, put the tube in the tube plate hole in metal cutting off part of the expansion, method can be removed from the pipe tube plate by chipping the demolition of the tube, can use the expansion part of the chisel tip nozzle to shrink, the tube and tube plate is disengaged the pipe from the the removal of the orifice tube plate down.

For larger pipe wall thickness, the oxygen acetylene flame cutting method is the first part of the demolition, the pipe expansion cut out 2-4 gap, and the nozzle to knock contraction, make off orifice tube and tube plate on the top, and then pull out the pipe or tool pull screw jack.

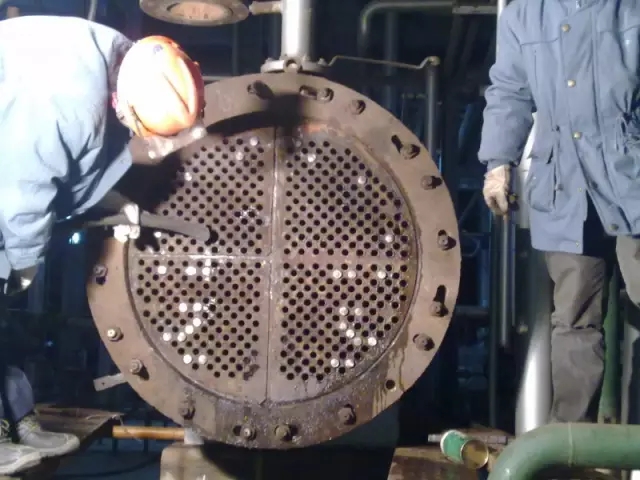

No matter what kind of method should be removed the pipe, the two ends of the pipe are removed, and pay attention not to damage the orifice tube plate in the demolition, when to replace the new pipe, the pipe connection is tight and tube plate.

(2) replace the new pipe and expand

The damaged pipe can be inserted into the hole of the tube plate after the pipe is drawn out of the tube plate. Replace the new pipe with the same material as the original pipe.

Through the tube, the tube plate hole is corresponding to the response, in the correct position. Then you can connect the tube to the tube plate.

Method for connecting pipe and tube plate by expanding and welding method.

1) expansion method

The expansion method is the use of tube expander, the stretching pipe pipe end portion of the plate hole rolling, pipe wall of the expansion pipe diameter, pipe diameter increases, completely fit in the tube plate hole on the inner wall of tube plate hole of the pipe end tightly, thus greatly both tight and firm connection to.

The heat exchanger pipe repair of expansion, usually use manual inclined column tube expander. The main parts are the expansion rod, and roller shell is composed of three parts.

In order to make the tube expansion more firmly, but also to extend the pipe end part of the tube plate flanging, then you can use flanged roller tube expander. Flanged roller tube expander is three more than the manual flanging roller inclined column expansion.

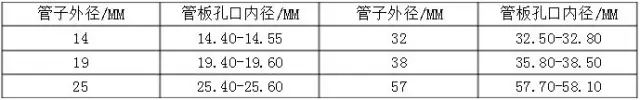

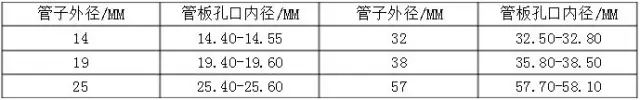

The tube expanding before, should the tube plate hole wall and pipe end by clean, to expose the metal luster, and the wall end of the annealing process of pipe diameter and pipe diameter of the orifice dimensions, its size should be consistent with the table shown in the numerical range:

The corresponding numerical range of tube diameter and tube in orifice

When the working temperature of the expansion pipe should not be less than -10 DEG C, expanding operation, first at the end of the tube wall coated with oil a little, put the tube expander into port tube, conical expansion rod is inserted into the three roller, the roller and the tube foot near the handle in the head of the party will take the expansion rod square hole, in the hands of light weight at the same time, clockwise rotate the handle, and drive the roller rotation, with the advance of the expansion rod roller, the pipe inner wall of the pipe wall swell rolling strengthening.

tightAttached to the inner wall of the tube orifice on the expansion after the completion of the operation, should first check whether the nozzle is crooked, transition part is smooth, no cracks on the flange. If there is a serious defect, the pipe should be replaced.

Finally, the hydrostatic test method to conduct a comprehensive inspection, pressure test, the tube bundle is arranged in the housing, the tube filled with water filling pressure, check the expansion interface without sink drain phenomenon, if there is Water Leakage or sweating phenomenon, re expansion of the expanding interface.

Expansion method is usually used in the pressure of 25× 100000Pa, the temperature is not greater than 300 degrees.

2) welding method

When the temperature and pressure of the medium is high or the requirements are more stringent, the tube can be fixed on the tube plate by welding.

In the case of strict requirements for the connection between the pipe and the tube plate, the method can be used to weld the two after expansion.

Due to the expansion of the county pipe, reduce the gap between the tube and the tube plate hole wall, which can reduce or eliminate the gap corrosion, improve welding quality, prolong the service life.

3) explosion tube expansion

The explosive expansion tube is a new technology of tube and tube plate connection hole. The principle is the use of high energy explosives, the explosion in time, resulting in a high pressure, high pressure gas in the tube side and under the effect of shock wave, rapid plastic deformation, firmly attached to the tube plate hole on.

When the pipe end of the outer circle and the inner circle of the orifice tube clean, the leakage of metallic luster, and the pipe orifice tube passed, then filled with explosives into the detonator tube end, placement of explosives and detonators and pipe must be coaxial, to ensure that when the explosion expansion relay uniform.

The axial position of the explosive in the pipe end. In front of the tube opening may rupture, may cause pipe rupture or middle tube necking on time.

The electric detonator, at the time of the explosion under tremendous pressure, the pipe end tightly expanding in the tube plate hole, one can also blast expanded pipe expansion pipes, each detonator must use the same batch of wire material, each detonator should be the same, so that the pipe end initiation time unified to ensure the quality of explosive expansion.

Both ends of a tube at the same time not to end the first explosion explosion, the other end end zaibao. The amount of explosive is the key to the expansion of the quality of the joint, the explosive is easy to expand the tube for a long time, the explosive can not guarantee the quality of expansion joints. Prior to the construction of the best simulation test to determine the amount of explosives.

The method of explosion expansion pipe is low cost, simple operation, small amount of labor, but must be very careful in operation, pay attention to safety.

Aspect 03: repair method of pipe vibration

Heat exchange tube heat exchanger vibration is another form of common faults. The vibration of the pipe will loosen the expansion joint of the pipe end, so that the contact between the pipe and the baffle plate can be worn, and the service life of the tube bundle can be reduced. Therefore, the vibration of the pipe should be taken in time to repair, so as to avoid the accident.

The vibration of the pipe is nothing more than the gap between the tube and the baffle plate, which is caused by the flow of the medium pulse. For the expansion of the pipe joints loose, can be used to repair welding. In order to reduce welding stress, small current arc welding should be used.

For the vibration between the tube and the baffle plate is too large, resulting in the wear between the tube and the baffle plate, depending on the degree of wear and tear to take different repair methods. If the wall is badly worn, the replacement of the new pipe can be used for repair.

If the wall wear, should find ways to reduce the gap between the tube and the baffle, such as increasing the number of baffles, or wood between pipe and pipe, so as to reduce and eliminate the vibration of the pipe.

As to the vibration of the pipe caused by the medium pulse flow, it is necessary to eliminate the pulse flow of the medium to reduce the possibility of vibration. For example, a buffer is arranged in the pipeline, so that the flow of the media tends to be stable, and the vibration caused by the pipe is eliminated.

— THE END—

Process equipment network release, please indicate the source.

WeChat official