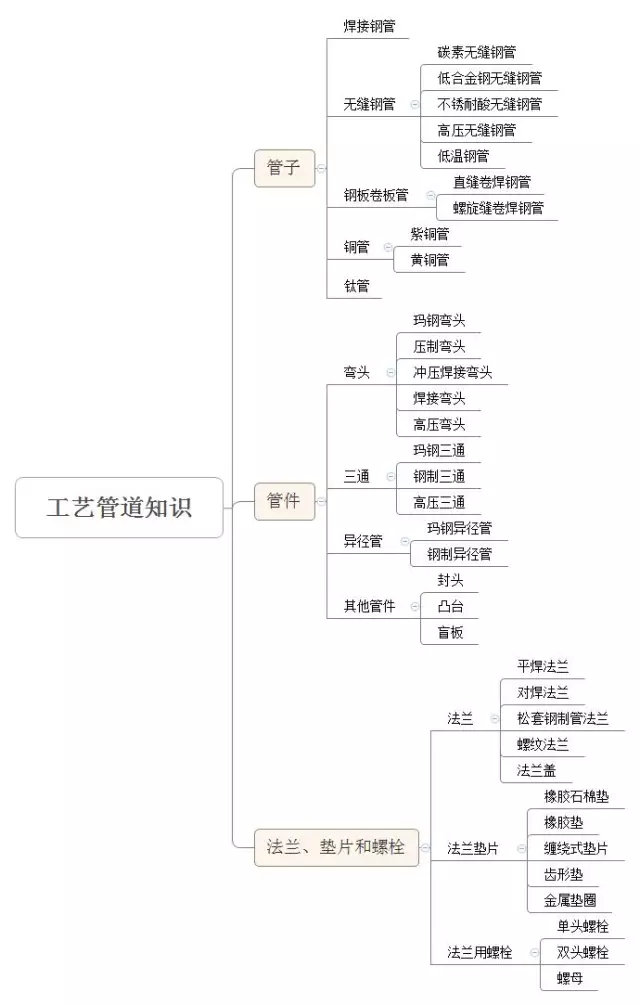

A figure can really understand the process piping knowledge! 5 tubes, 4 types of pipe fittings, flanges, gaskets and bolts, in fact, is so simple!

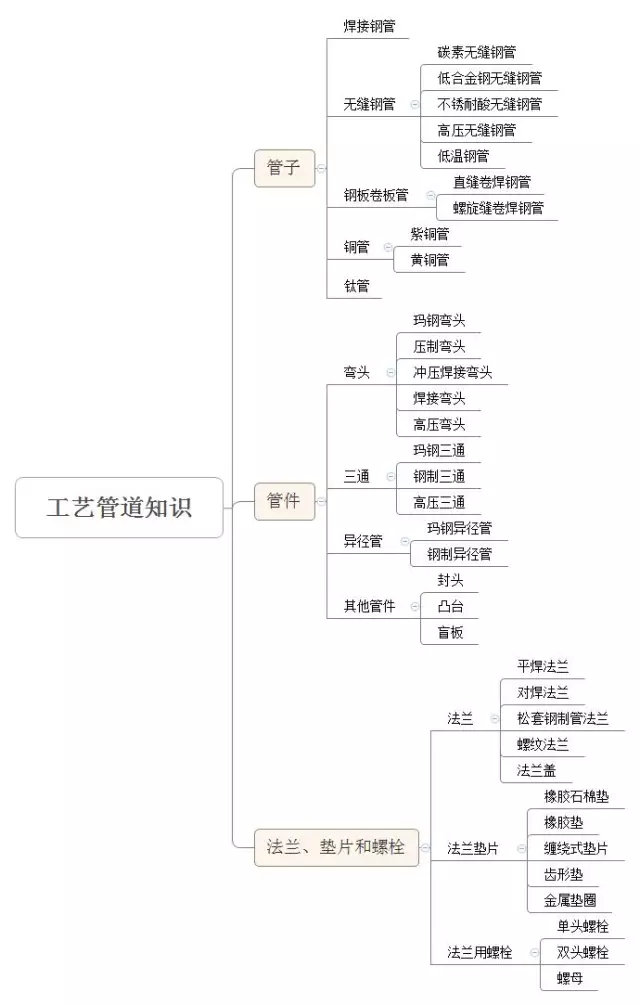

Content framework

You

Text

You

Tube

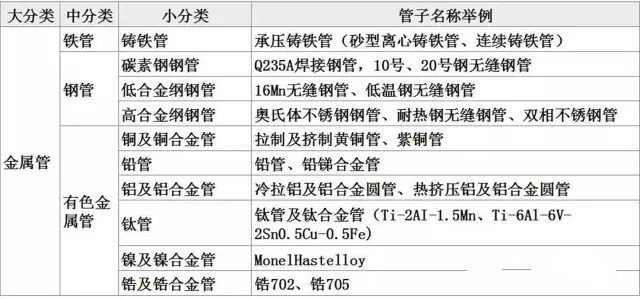

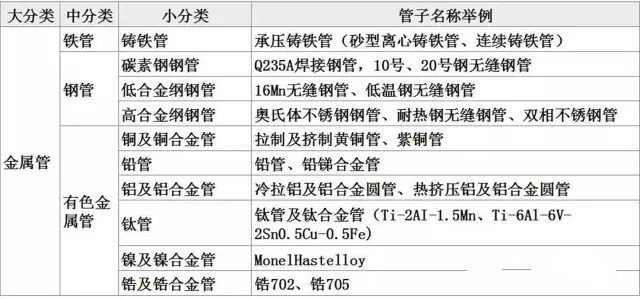

A lot of the classification method, according to the classification of material of metal pipe, metal pipe and non liner non metal composite pipe.

Non metal pipes are mainly rubber pipe, plastic pipe, asbestos cement pipe, graphite tube, glass steel, non metal pipe with metal tube with a smaller proportion of the metal pipe in most petroleum chemical equipment accounted for all the above process piping installation eighty-five percent.

Today, we focus on metal pipe.

The classification of metal pipe

1 welded steel pipe

Welded steel pipe, also known as pipe joints, usually by welded steel or steel roll.

According to the surface treatment of pipe:

Divided into two kinds of zinc and zinc plating. Galvanized surface hair white, also known as tin pipe or galvanized steel pipe; the surface is ordinary galvanized welded steel pipe, also known as black pipe.

Galvanized welded steel pipe, used for conveying medium piping clean, such as water, air purification, instrument air; galvanized welded steel pipe, can be used for conveying steam, gas, compressed air and condensed water etc..

According to the requirements of users, the welded steel pipe can be divided into two kinds:

The utility model is characterized in that the pipe end is provided with a screw thread, and the other end of the pipe end is provided with no thread. The end of the pipe with a threaded welded steel pipe, the length of each pipe is 4 ~ 9m, without threaded welding steel pipe, the length of each pipe is from 4 to 12m.

Welded steel pipe according to the thickness of the wall:

Divided into thin-walled steel pipe, thick steel pipe and ordinary steel pipe. The most commonly used in the process pipeline is the ordinary steel pipe, the test pressure is 2.0MPa. The test pressure of thick steel pipe is 3.0MPa.

Welding steel pipe connection method:

Threaded connection, flange connection and welding. The flange and threaded flange and welding flange connection, welding method and welding and arc welding is divided into.

Commonly used welded steel pipe specifications: nominal diameter of 6 ~ 150mm

2 seamless steel tube

Seamless steel pipe, is the largest industrial pipeline, the largest number of varieties of pipe specifications.

Basically divided into:

Seamless steel tubes for fluid delivery and two types of seamless steel tubes with special purpose. The former is commonly used in the process of steel pipe, such as the boiler, such as steel tubes, cracking furnace tubes and heat exchanger tubes.

According to the material can be divided into:

Carbon seamless steel pipe, chromium molybdenum seamless steel pipe and stainless steel pipe.

According to the nominal pressure can be divided into:

Low voltage (0≤ 1.0MPa), medium pressure (1 = 10MPa = high pressure (≥ 10MPa) class three.

Process piping is commonly used in fluid transport seamless steel pipe. Classification as follows:

Carbon seamless steel pipe

Commonly used for the manufacture of materials 10, No. 20, 16Mn steel.

The range of specifications for hot rolled &phi diameter; 32 ~ 630mm, 6 ~ 200mm drawing &phi diameter; root canal length, 4 ~ 12M, allowable operating temperature of -40 to 450 DEG C.

It is widely used to transport all kinds of corrosive medium, such as steam, oxygen, compressed air, oil and gas.

Low alloy steel seamless steel pipe

Alloy steel tube containing a certain proportion of alloying elements.

Usually divided into two kinds:

One is a low alloy steel pipe containing manganese, known as ordinary low alloy steel pipe, such as 16Mn, 15MnV, etc.; the other is containing chromium, molybdenum and other elements of the low alloy steel pipe.

Commonly used are 12CrMo, 15CrMo, 12Cr2Mo and 1Cr5Mo, the range of specifications for &phi diameter; 10 ~ φ 273mm, a single tube length of 4 ~ 12M, suitable temperature range of chrome molybdenum steel tube is -40 to 550 DEG C.

Low alloy seamless steel pipe, used to transport a variety of high temperature oil, oil and gas and corrosive water is not strong, low concentration of organic acids, etc..

Stainless seamless steel pipe

According to chromium, nickel, titanium metal content of different varieties, there are Cr13, 00Cr17Ni14Mo2, 1Cr18Ni12Mo2Ti, 1Cr18Ni9Ti, etc..

The steel is the largest amount of 1Cr18Ni9Ti, in the construction of common simplified material code 18-8, suitable temperature range of -196 to 700 DEG C.

In the chemical industry used to transport a variety of corrosive medium, such as nitric acid, acetic acid and urea, etc..

High pressure seamless steel pipe

The material is similar to that of the seamless steel tube, but the tube wall is thicker than the middle and low pressure seamless steel pipe, and the thickness of the pipe wall is up to 40mm.

Such as chemical fertilizer equipment with high pressure seamless steel pipe specifications for φ 14× 4 (mm) ~ 273× 40 (mm), a single tube length of 4 ~ 12M, the applicable pressure range of 10 ~ 32MPa, the temperature of -40 to 400 DEG C.

In the petrochemical plant, the above high pressure seamless steel tubes are used to transport raw material gas, hydrogen nitrogen gas, synthetic gas, water vapor, high pressure condensed water, etc..

Low temperature steel

In the introduction of the cold area of the project more dosage, the material is STPL-39, STPL-46, the working temperature of -105 C.

Low temperature steel pipe seamless steel pipe and pipe joints is divided into two kinds, seamless low nominal pipe diameter is 15 ~ 400mm, the wall thickness of the carbon steel welded steel pipe; low nominal diameter is 400 ~ 1100mm, the wall thickness is 6 ~ 10mm, single tube standard length 6m.

The utility model is suitable for conveying various corrosion free low temperature medium pipes, and at present, there is no batch production of the corresponding steel pipes in this country.

3 steel pipe rolling

Steel coil tube is welded by steel plate rolling, divided into straight seam welding steel pipe and spirally welded steel pipe volume two.

Straight seam welding steel pipe:

Majority in ShiWork site manufacturing or commissioned by the processing plant manufacturing, professional steel pipe factory does not produce.

Steel materials are Q235A, 10, No. 20, 16Mn, 20g, etc., the specification of the nominal diameter of 200 ~ 3000mm, the largest 4000mm, wall thickness is generally between 4 ~ 16mm.

The nominal diameter of 200 ~ 900mm single tube length is 6.4m; the nominal diameter of 1000 ~ 3000mm for 4.8m.

Applicable operating temperature: Q235A is -15 ~ 300 DEG C, No. 10, 16Mn, 20g, -40 ~ 450, suitable for low voltage range.

Spiral seam welded steel pipe:

Produced by the steel pipe factory, the material is Q235A, 16Mn.

The specifications for the nominal diameter of 200 ~ 700mm, 7 ~ 10mm thickness, root canal length ranged from 8 to 18m.

Applicable operating temperature: Q235A is -15 ~ 300 DEG C, 16Mn is -40 ~ 450 DEG C, operation pressure: Q235A is 2.5MPa, 16Mn is 4MPa.

Straight seam welding steel pipe and spirally welded steel pipe used for conveying volume, normal temperature and low pressure is not strong corrosive medium, such as steam, water, gas and underground circulation of oil and gas etc.. Spiral seam welding steel pipe of single pipe is longer, especially suitable for long distance pipeline.

According to the needs of the project, as well as straight rolled steel plate welded pipe, are in the winding construction site, factory production. Most of the materials used for 1Cr18Ni9Ti steel plate. The size range of nominal diameter is 200 ~ 1000mm, 200 ~ 400mm nominal diameter and wall thickness of 4mm, nominal diameter 700 ~ 1000mm thickness is 6 ~ 8mm, single tube length is 4.5m. Applicable temperature and delivery medium range with low pressure stainless steel pipe.

4 Brass

Two kinds of copper tube and copper tube:

The materials used in the manufacture of copper tubes are T2, T3, T4 and TUP, etc., with a higher copper content, accounting for more than 99.7%;

Yellow brass manufacturing materials are H62, H68, etc., are zinc and copper alloy, such as H62 brass tube, the material composition of copper 60.5% ~ 63.5%, zinc is less than 0.5%, other impurities.

Manufacturing method of copper tube is divided into two kinds of drawing and extrusion:

Drawing the outer diameter of the copper pipe is φ 3 ~ φ 200mm, the extrusion of the outer diameter of the copper pipe is φ 32 ~ φ 280mm, the wall thickness is 1.5 to 5mm;

Copper welding tube specifications range of diameter φ 155 ~ φ 505mm, a single disc and two delivery ways.

The working temperature of the copper tube is below 250 DEG C, which is mainly used in oil pipelines, heat preservation pipes and air separation oxygen pipelines.

5 titanium tube

Titanium tube is a new kind of tube in recent years. Because of its light weight, high strength, corrosion resistance and low temperature resistance, it is often used in other parts of the pipe can not be competent.

Titanium tube is made of TA1, TA2 industrial pure titanium, suitable for the temperature range of -140 to 250 DEG C, when the temperature exceeds 250 degrees C, its mechanical properties decreased.

Commonly used titanium tube specifications for the nominal diameter of 20 ~ 400mm. Suitable for low and medium pressure, low pressure pipe wall thickness 2.8 ~ 12.7mm, medium pressure pipe wall thickness of 3.7 ~ 21.4mm.

Titanium tube has many advantages, but it is difficult to be welded because of its high price.

Pipe fitting

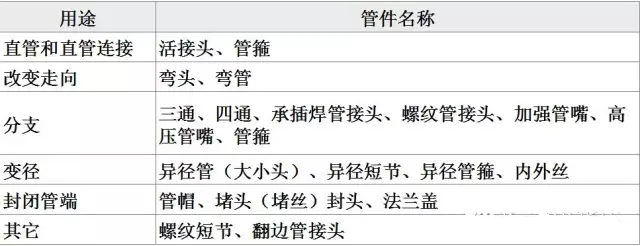

Change direction, elevation or changing the diameter and lead by the competent branch is required in the piping fittings. Because the pipe shapes and simplified range, therefore, more types of fittings.

The commonly used pipe elbow, three, different diameter pipe, pipe fittings, pipe cap etc..

Classification by use of long pipe

1 elbow

Elbow is used to change the direction of the pipeline.

The bending angle of the commonly used elbow is 90° 45° and 180° 180° the elbow is also known as the U type elbow, but also has the special angle elbow, but few.

Steel elbow

They also called malleable iron elbow, elbow, elbow is the most common thread.

The relatively small size of steel elbow, common specifications range from 1/2 to 4 inches, according to the different surface treatment and two kinds of galvanized galvanized.

This is mainly used for heating, pipe fittings, water pipes and gas pipes. In the process, in addition to the need for regular removal of the low-pressure pipeline, the use of other materials rarely.

Suppress elbow

Suppress elbow, also known as stamping elbow or seamless elbow, is stainless steel and low alloy steel seamless tube for high quality steel, and pressed in a special mold.

The bending radius of the nominal diameter of one and a half (R=1.5DN), in special occasions can also be used to bend the radius is equal to the nominal diameter of the elbow (R=1DN).

Its specifications range from DN20 to 600mm.

The thickness of the wall is the same as that of the seamless steel tube.

Factory or processing factory with standard seamless steel stamping processing and general manufacturing by professional factory suppress elbow, elbow ends shall be machined groove.

Stamping welding elbow

Stamping welding elbow, is the use of sheet metal stamping into a semi - circular elbow, and then the two - half ring of the group of welding.

The bending radius is the same as the seamless pipe elbow, the specification range is above 200mm.

Welding elbow

Welding elbow, elbow or waist also small shrimp shrimp.

There are two ways to make:

One is the material for the steel plate in the processing plant, cutting after coiling welded steel plate used for supporting the most.

The other is the use of pipe material, the formation of the welding of the group, its specifications are generally more than 200mm. The use of temperature can not be greater than 200 degrees, generally in the construction site.

High pressure elbow

High pressure elbow, is the use of high-quality carbon steel or low alloy steel forged.

According to the pipe joint, elbow ends are processed into thread or groove, the processing precision is high, pipe thread and flange screw thread required to closeTight fit screw in and not loose.

Suitable for pressure 22, 32.0MPa petrochemical pipeline, commonly used specifications range from DN6 to 200mm.

2 three links

The three way is the main pipe and branch pipe connecting pipe fittings, according to the manufacturing material and the use of different, divided into many kinds.

Divided from the specification:

Can be divided into three channels with the same diameter and the diameter of the three links, with the diameter of the three channel is also known as equal diameter of three;

The three channel with the same diameter is the same diameter as the pipe diameter

Different diameter three pass refers to the branch pipe diameter is less than the diameter of the pipe, so also known as the unequal diameter of the three pass, the diameter of the general amount of more than three

Malleable iron three

Three the malleable iron manufacturing material and the size range, with the same steel in petrochemical process pipe elbow, in amounts, mainly used for indoor heating, water and gas pipelines.

Steel three

Before twentieth Century, the speed of the development of industrial production technology in China was relatively slow, and the engineering technology of process pipeline was also relatively backward in the year of 70s.

In all kinds of design of low voltage steel pipe, three pipe pipeline, are generally used to take over exoculation solution, namely in the branch pipe head, the diameter of the first branch to dig a hole, and then welded pipe. This approach has many disadvantages, the quality of welding is not easy to guarantee, easy deformation of the pipeline after welding, easy access to impurities within the supervisor.

In late 70s, with the introduction of metallurgy, petrochemical and other large modern production equipment, and promote the development of engineering technology of pipeline technology at present, our country has been able to in the production of low pressure pipeline steel type three, has formed a series of products, seamless three specifications for DN20 ~ 600mm, welded steel specifications for the DN150 ~ three 1500mm.

Three the production type, is made of high quality material as raw material, after cutting, gouge out your eyes, after heated mould drawing made by machining, become stereotypes finished three. Medium and low pressure steel three pass, in the field of welding is used to install. The steel plate three, there are two cases, one is the material for steel plate in the processing plant, after rolling and welding; the other one is at the installation site over exoculation.

Pressure three

High pressure three pass, there are commonly used in the two, one is the high pressure welding of the three pass, one is the overall forging of high pressure through three.

Three high pressure welding, selection of high quality high pressure steel tube material, manufacturing method of similar exoculation over the head of the hole, to be consistent with the pipe diameter. The welding quality is strict, and it usually requires preheating before welding and heat treatment after welding. Its specifications range from DN16 to 200mm, pressure 22MPa, 32MPa.

The overall forging of high pressure three pass, the general use of threaded flange connection. The scope of the specification for the table number SCH160, DN15 ~ 600mm, table number plus “ XXS” its diameter range of DN15 ~ 300mm.

3 different diameter pipe

Different diameter pipe is the role of the pipe diameter, the fluid flow direction, the majority is from big to small, also some change from small to big, such as steam return pipeline and water pipes of different diameter pipe is from small to large. Commonly known as the small diameter pipe.

Malleable iron reducers

Malleable steel different diameter pipe, can be divided into two kinds, one is the internal thread of different diameter pipe also called foreign joint; the other is a pipe with internal and external threads, called the core, although it is not called the different diameter pipe, but played the role of different diameter pipe.

Steel different diameter pipe

Steel tubes of different diameters, divided into two kinds of seamless and welded and seamless different diameter seamless steel pipes for different diameter pipe pressing, seamed steel cutting system, scroll welding, also known as welded tubes of different diameters.

There are two kinds of different diameter pipe concentric and eccentric specifications of the two. The bottom of the eccentric reducing pipe is provided with a straight edge, and the bottom of the pipe can be used to form a horizontal surface when the utility model is used, which is convenient for discharging the material in the discharge pipe.

Seamless tube diameter size range is DN25 ~ 600mm, with different diameter pipe welding specification range is DN200 ~ 1500mm.

Steel different diameter pipe, pipe fittings as finished, just after 70s, reducing the early process pipeline, mostly in the field of production. The change of pipe diameter is very large in the end of the pipe welding, directly into a different diameter pipe;

Pipe diameter changes little in the end of the tube heating directly fall into. The production of different diameter pipe, the cost of labor and more welding, welding quality is not easy to ensure that, at present, the quality of the welding process requirements of the pipeline has been prohibited by this approach.

4 other pipe fittings

Head

The head is used for sealing the pipe end. There are two kinds of commonly used heads, oval and flat.

Elliptical head is also known as the cap, the size range of DN25 ~ 600mm, much used in low-pressure pipeline.

The flat cover head is divided into two kinds according to its installation position, one is that the flat cover head is slightly larger than the outer diameter of the pipe.

The other is that the flat cover is less than the inner diameter of the pipe, and the end plate is put into the tube. Commonly used specifications range from DN15 to 200mm, the head of the pipe used in low pressure.

Boss

Boss, also known as the tube mouth, is a professional instrument control in the process of the pipeline on the part of the process is to install the pipeline to the professional, so the boss is also classified as pipe fittings.

Single pipe joint for pipeline belongs to this kind, are in charge of welding at one end, the other end is installed or other components, or another over the size range of DN15 ~ 200mm, use of high pressure pipeline.

Blind

Blind plate, its role is to cut off the pipeline medium, according to the use of pressure and flange sealing surface of the following types:

The utility model relates to a smooth surface blind plate, which is matched with a smooth sealing surface flange and is suitable for the pressure range of 1 to 2.5MPa.

The convex blind plate, its side with convex, the other side with concave, with a concave and convex flange sealing surface. The use of pressure 4.0MPa, specifications range from DN25 to 400mm.

Trapezoidal groove blind plate, and trapezoidal groove sealing flange with the use of the pressure range of 6.4 ~ 16.0MPa. Specifications range from DN25 to 300mm.

“ 8” word blind, also divided into smooth, concave convex and trapezoidal groove face three, the use of pressure and more than three kinds of blind plateIn the same way, “ 8” the word blind plate is different, it combines the two purposes on a component, the blind plate and the washer is connected and fixed together. When the flange is inserted into the blind plate, the outer washer is used as an indication of whether the pipe is cut off.

“ 8” the word blind plate manufacturing materials have a variety of, according to the medium temperature and pressure to choose. General low pressure pipeline, the temperature is not more than 450 degrees C, the material used is Q235A, No. 20 steel and No. 25 steel; temperature at 450 to 550 DEG C, the materials used are 15CrMo. When the pressure in the 4 ~ 16.0MPa, the temperature is greater than 550 degrees, the use of stainless steel.

Flanges, gaskets and bolts

1 flange

Flange is a part of the process pipeline connection. The application of this type of connection is very extensive, such as the pipeline and process equipment, pipeline flange valve and accessories. Flange connection has the flexibility of installation and disassembly, and reliable sealing.

Pipeline technology of the media, a wide range of temperature and pressure are also different, so the flange strength and sealing, put forward different requirements. In order to meet the needs of the process pipeline installation, a lot of different structures and different pressure flange.

The following is a brief introduction to various flanges:

Flange

Flat steel is in low pressure pipeline flanges, one of the most commonly used.

The flange and pipe in the form of fixed, the flange is set at the end of the pipe, welded flange inside and outside the mouth, so that the flange is fixed, the nominal pressure is not more than 2.5MPa.

For carbon steel pipe connection flange, with the general Q235A and No. 20 steel plate manufacturing;

Used for stainless steel pipe flange acid on the stainless steel tube with the same material manufacturing application.

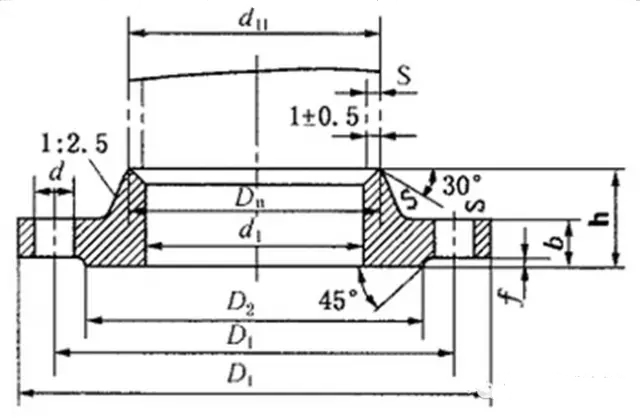

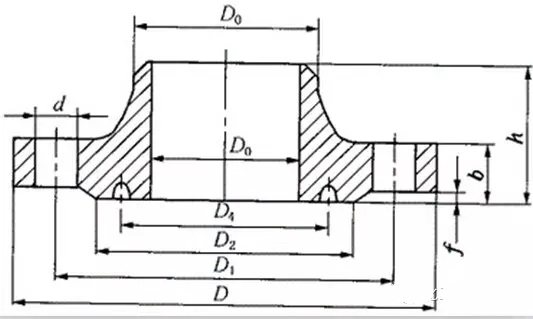

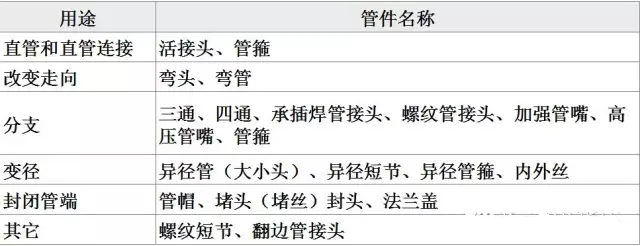

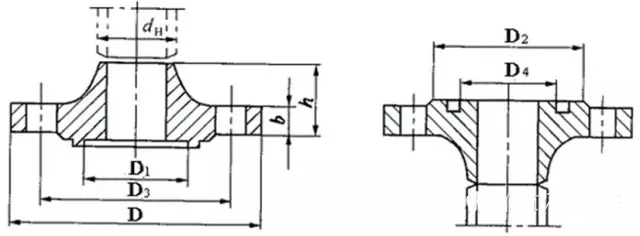

Flat steel flange sealing surface is generally smooth, sealing surface is processed with a shallow trench. Often referred to as the waterline, fig.:

Long flat steel flange drawing

Welding steel flanges specifications are as follows:

Nominal pressure PN0.25, 0.6MPa for DN10 ~ 2000mm;

PN1.0 ~ 2.5MPa for DN10 ~ 600mm.

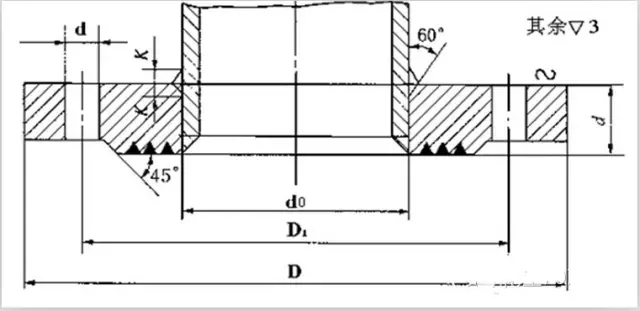

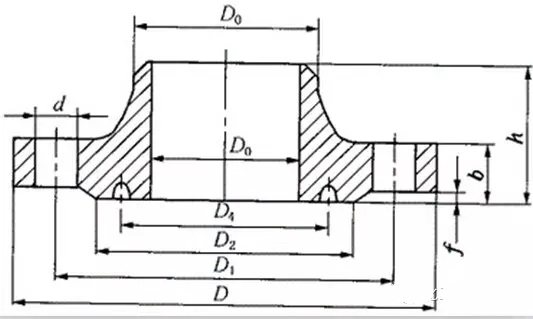

Welding flange

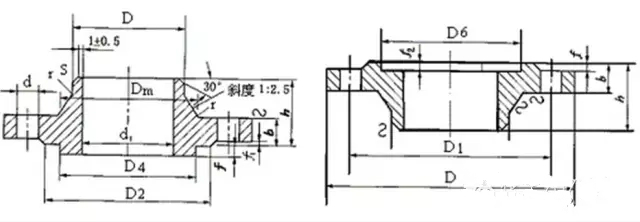

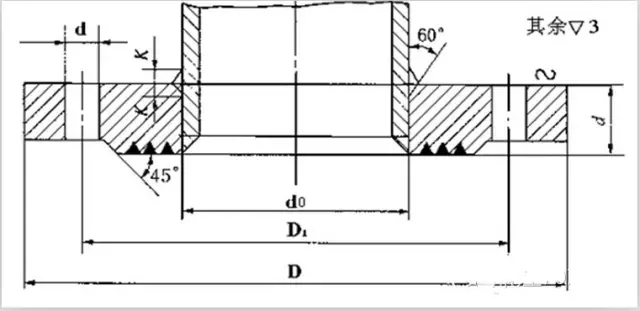

Butt welding steel flanges, also known as the high neck flange or tail flange. The utility model has the advantages of large deformation, good sealing performance and various sealing surfaces, and the pressure range is very wide.

1.

Smooth face welding flange, the nominal pressure is below PN2.5MPa, specifications range is DN10 ~ 2000mm, nominal pressure PN2.5MPa, specifications range DN10 ~ 1000mm, nominal pressure PN4.0MPa, specifications range from DN10 to 600mm, as shown in fig.:

The smooth face welding flange drawing

2

The concave and convex seal faces the welding flange, because the concave convex sealing surface is tight, the pressure is large. The sealing surface of each flange must pay, one is, the other is a convex concave. Commonly used nominal pressure range of PN1.6 ~ 4.0MPa, the specification range of DN10 ~ 600mm, as shown in figure:

The convex sealing face of welding steel flange drawing

3

The sealing face of groove welding flange, the flange sealing performance, structure of a similar bump type sealing surface of flange is a flange must be two supporting the use of. Nominal pressure range of PN1.6 ~ 4.0MPa, the specification range of DN10 ~ 600mm; PN6.4 ~ 10MPa, the specification range of DN10 ~ 400mm, as shown in figure:

The tongue and groove face flange welding diagram

4.

The trapezoidal groove seal face welding flange, the flange pipe commonly used in petroleum industry, under pressure, commonly used nominal pressure PN6.4, 10.0MPa, specifications range from DN10 to 400mm; PN16MPa, range of DN10 ~ 300mm specifications. As figure:

The trapezoidal groove face welding steel flange drawing

The welded flange, just according to the sealing surface in the form of different distinction.

From the installation point of view, whether it is in the form of welded flange, the connecting method is the same, so the consumption of labor, materials and machinery, is basically the same. However, due to the different forms of the sealing surface, flange manufacturing costs vary greatly, therefore, in the preparation of the (pre) to pay particular attention to the price of the flange itself.

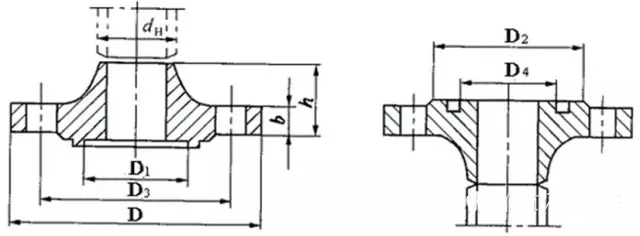

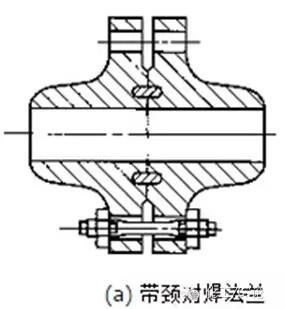

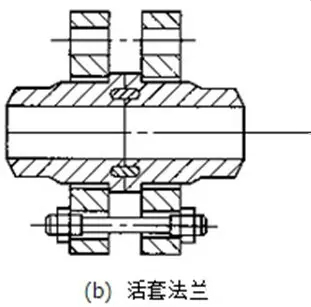

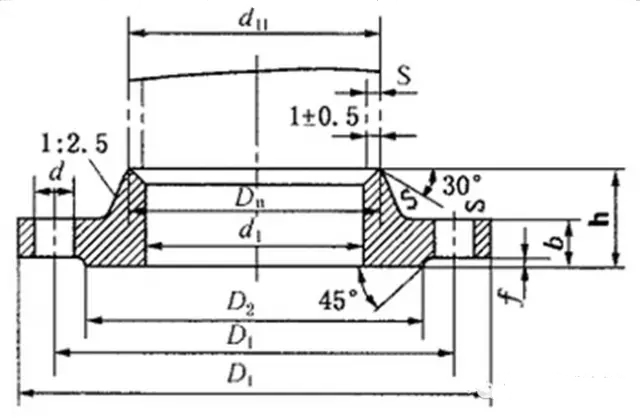

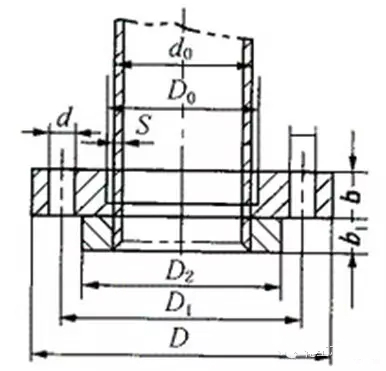

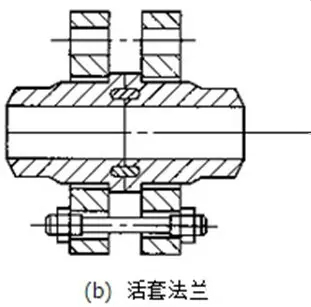

Loose steel pipe flanges

The flange and pipe are not directly welded together, but by orifice flanging or welding ring for sealing contact surface, loose flange fastening, used for copper, aluminum and lead other non-ferrous metal and stainless steel pipe.

The biggest advantage is that the flange can be free to move, the flange is very convenient to wear bolts.

Welding ring loose steel pipe flanges for pressure PN0.6 ~ 2.50MPa, its size is in the range of DN10 ~ 600mm; pressure PN4.0MPa, specifications range DN10 ~ 300mm, flat ring loose steel pipe flanges for low pressure PN0.6 ~ 1.6MPa, the range of DN10 to 600mm specifications. Nozzle flange looper method is only suitable for PN06MPa and below.

Welding ring loose flange as shown in figure:

The welding ring loose steel pipe flanges figure

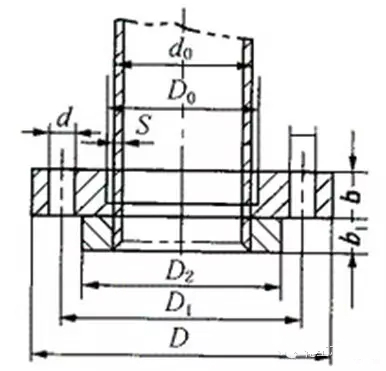

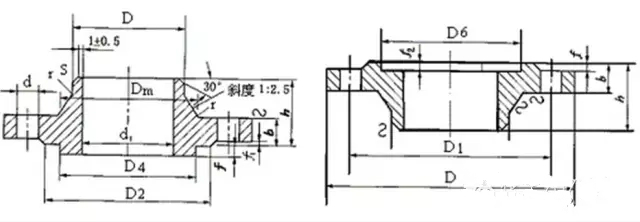

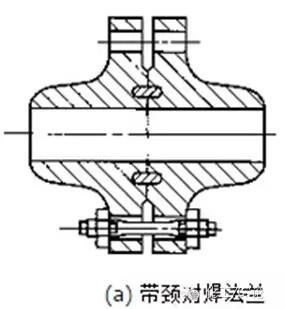

Threaded flange

Threaded flange, is a threaded flange and the end of the threaded pipe flange, there are two kinds of high pressure and low pressure.

Low pressure screw flanges, including two types of steel and cast iron, which were widely used in the early years of the founding of the PRC, with poor welding technology.

With the development of the industry, has been replaced by low pressure threaded flange flange, except in special circumstances, not by.

High pressure threaded flanges are widely used in modern industrial pipe connections. Sealed by tube end and lens washerForming, the thread and the end of the pipe gasket surface precision processing requirements.

The flange is characterized by the flange and the tube does not contact the media, installation is also more convenient. Applicable pressure PN22.0, PN32.0MPa, the specification range of DN6 ~ 250mm.

The high-pressure pipeline flange connection structure diagram

Flange cover

Flange cover is used with the flange components, it is the same as the head of the pipe at the end of the role of closure. Sealing surfaces are smooth and convex concave type, specifications and applicable pressure range consistent with flange.

2 flange gasket

Leakage is the main form of pipe flange failure, which is related to many factors, such as the sealing structure, the rigidity of the connector, the performance of the seal, operation and installation.

Gasket is the main seal flange connection, so the correct selection of gasket is also the key to ensure that the flange connection does not leak.

Flange gasket according to the pipeline medium corrosion, temperature, pressure and flange sealing surface of the form of choice of many. The pipe flange gasket is made of non-metallic gasket, semi metal gasket and metal gasket.

Rubber asbestos gasket

Rubber asbestos gasket is the largest amount of flange gasket, can be used in many media, such as steam, gas, air, salt water, acid and alkali, etc.. The thickness of rubber asbestos pad, the professional is not uniform, usually with 3mm thick. Nominal diameter less than 100mm of the flange, the gasket thickness of not more than 2.5mm.

Gasket pressure: for smooth sealing surface flange connection, not more than 2.5MPa.

There are two kinds of rubber asbestos gaskets used in oil refining industry:

The utility model relates to an oil resistant rubber asbestos pad, which is suitable for medium temperature below 200 DEG C and nominal pressure below 2.5MPa. High temperature oil resistant rubber asbestos pad, the use of temperature up to 350 ~ 380 C.

The other is medium pressure rubber asbestos pad, can be used at 200 degrees C, PN2.5MPa below the steam, condensate, water, air and other media.

Rubber pad

Rubber pad, is made of rubber sheet gasket, it has a certain degree of corrosion resistance, commonly used in the temperature of 60 degrees Celsius, the pressure is not more than 1.0MPa, the delivery of low pressure water, acid and alkali and other medium pipe flange connection.

The characteristics of the gasket is the use of rubber elasticity, to achieve a good sealing effect, it is also commonly used in the installation of cast iron flange valve.

Spiralwound gasket

The utility model relates to a spiral wound gasket, which is referred to as a winding pad.

The utility model has the advantages of simple manufacture, low cost, good utilization of the material, and good sealing performance, and is widely used in the petrochemical process pipeline.

Applicable parameters: applicable nominal pressure of 4.0MPa, applicable temperature range, 08 steel temperature up to 450 degrees C, 0Cr13 steel tape winding pad, the use of temperature up to 540 degrees C. The thickness of the gasket is generally 4.5mm, the diameter is greater than 1000mm, the gasket thickness of 6 ~ 7mm. The thickness of the positioning ring is about 3mm.

This gasket is mostly for smooth flange, the sealing surface without water. Some winding pads, also with a positioning ring, in order to prevent the gasket from the flange center.

The metal strip material is 08 steel, 0Cr13 steel and 1Cr18Ni9Ti steel, etc. the non-metallic belt material is characterized by asbestos, flexible graphite, PTFE and so on.

Tooth pad

The tooth pad is made of metal material, ordinary carbon steel, low alloy steel and stainless steel, the thickness is 3 ~ 5mm.

It is the use of concentric circular tooth and flange sealing surface contacts, forty-five constitute multi seal, the sealing performance is good, is often used to connect the sealing surface of the concave convex type flange.

Applicable parameters: the maximum nominal pressure up to 16.0MPa, suitable for high temperature parts, such as 0Cr13 material of the tooth pad, its applicable temperature of 530 degrees C.

Metal gasket

There are many kinds of metal gaskets, the metal flat washers are divided by the shape, the sectional area is oval, octagonal metal washer and lens washer. According to manufacturing material with low carbon steel, stainless steel, copper, aluminum and lead etc..

Metal flat washers, for the smooth surface flange, withstand the pressure and the temperature are low.

Oval and octagonal metallic gaskets, used for trapezoidal groove butt welding flanges, nominal pressure range is 6.4 ~ 22.0MPa. Although the sealing gasket is good, but the production of complex, requiring high precision.

The lens pad, because of its shape like lens and its name, good sealing performance, in petrochemical production, all kinds of high temperature and high pressure pipeline flange connection, widespread use of such washers, commonly used nominal pressure range is 16 ~ 32.0MPa.

The use of metal washer has the principle that the hardness of the gasket surface must be lower than the flange sealing surface hardness.

The selection of gasket should be determined according to the temperature, pressure, corrosion and the sealing form of the connection flange. Professional gasket, such as lens pad, suitable for high pressure flange connection.

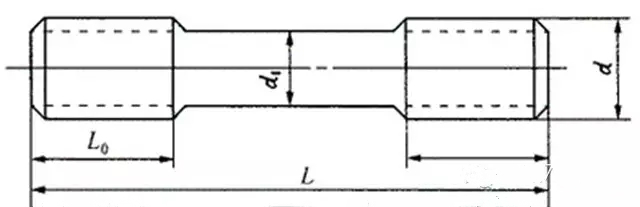

3 flange bolts

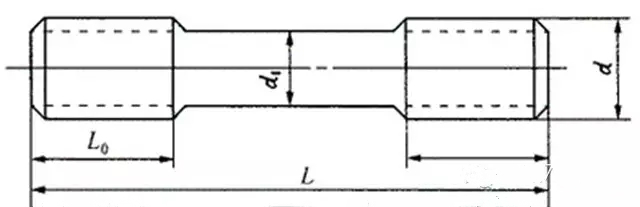

Bolt for connecting flange, there are two kinds of single head bolts and studs, the thread is generally triangular metric coarse thread.

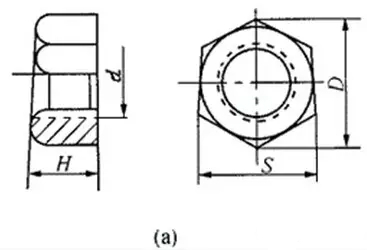

Single head bolt

Single head bolt, also known as six head bolt. Single head bolts are divided into two kinds of semi refined and refined, in the medium and low pressure pipeline, the most used is a semi refined single head bolts.

The manufacture of single head bolts commonly used materials are Q235A, 35 steel and 25Cr2MoVA, etc.. Commonly used in nominal pressure 2.5MPa below the flange connection.

Applicable temperature according to the bolt material, such as 35 steel bolts for the temperature of up to 350 degrees C; 25Cr2MoVA steel bolt, suitable temperature can reach 570 degrees C.

The single head bolt Tutu

The isometric stud map

Stud

Most of the double headed bolts used in the process pipe adopt the equal length double headed bolts. Suitable for high temperature and high pressure flange connection.

Material has 35 steel, 30CrMoA, 35CrMoA, 25Cr2MoVA, 0Cr19Ni9, 0Cr15Ni25Ti2MoAlVB and 37SiMn2MoVA, nominal pressure range of 1.6 ~ 32.0MPa, applicable temperature up to 700 degrees C.

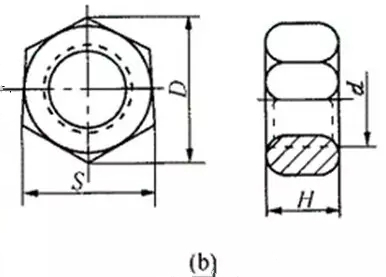

Nut

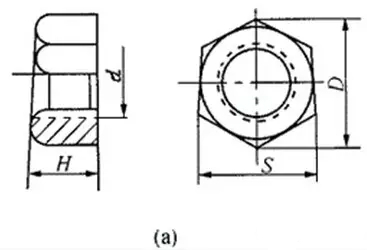

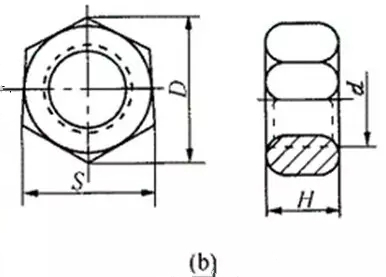

Nut, six angle nut. Semi refined and refined two kinds. According to the nut structure can also be divided into A type and B type two.

Semi refined single head bolts are more A type nut; refined double headed bolts using B nut. Nuts and bolts to be used, but the nut manufacturing material hardness can not exceed the hardness of the bolt material.

The six nut graph

— THE END—

Process equipment network release, please indicate the source.

WeChat official