Petroleum and chemical industry occupies a very important position in the national economy, and chemical process pump as a key supporting equipment has also attracted more and more attention. Due to the intricate characteristics of chemical media, coupled with the continuous improvement of environmental protection requirements, how should we choose the type of chemical pump? It is particularly important to focus on what aspects and so on. Today, Xiaobian is going to talk with you about matters needing attention in the selection of chemical pumps.

]

Precautions 1: corrosion resistance

All along, corrosion is one of the most headache hazards of chemical equipment, slightly inadvertent, light damage to equipment, serious accidents and even cause disaster.

According to relevant statistics, about 60% of the damage to chemical equipment is caused by corrosion, so the first thing to pay attention to when selecting the type of chemical pump is scientific.

There is usually a misconception that stainless steel is “ universal material ” it is dangerous to hold out stainless steel in any medium and environmental conditions. Below for some commonly used chemical media to talk about the main points of selection:

1 sulfuric acid

As one of the strong corrosive media, sulfuric acid is an important industrial raw material widely used.

Sulfuric acid with different concentrations and temperatures corrodes materials differently. Carbon steel and cast iron have better corrosion resistance to concentrated sulfuric acid with a concentration of more than 80% and a temperature of less than 80', but it is not suitable for high-speed flow of sulfuric acid and is not suitable for pump valve materials. Ordinary stainless steel such as 304 (0Cr18Ni12Mo2Ti) and 316 (0Cr18Ni12Mo2Ti) have better corrosion resistance to sulfuric acid. The medium is also of limited use.

Therefore, pumps and valves conveying sulphuric acid are usually made of high-silicon cast iron (casting and processing difficult), high-alloy stainless steel (20 alloy), but it is difficult to process and expensive, so it is not appreciated by people.

Fluoroplastic alloy has a good resistance to sulfuric acid. It is a patent material of Shanghai Institute of Organic Chemistry, Chinese Academy of Sciences. It has been proved by experiments of Chinese Academy of Sciences that no chemical medium can react with it. Therefore, it is a more economical choice to use fluorine-lined pump (F46).

2 hydrochloric acid

Most metal materials are not resistant to hydrochloric acid corrosion (including various stainless steel materials), molybdenum-containing ferrosilicon can only be used in 50 C, less than 30% hydrochloric acid.

Contrary to metallic materials, most non-metallic materials have good corrosion resistance to hydrochloric acid, so lining rubber pump and plastic pump (such as engineering plastics, fluoroplastics, etc.) is the best choice for the delivery of hydrochloric acid.

3 nitric acid

Most metals are rapidly corroded and destroyed in nitric acid. Stainless steel is the most widely used nitric acid-resistant material. It is worth mentioning that the corrosion resistance of stainless steel containing molybdenum (such as 316, 316L) to nitric acid is not better than that of ordinary stainless steel (such as 304, 321), and sometimes even better. Not as good as. For high temperature nitric acid, fluoroplastic alloy is usually used.

4 acetic acid

It is one of the most corrosive substances in organic acids. Ordinary steel will be seriously corroded in acetic acid at all concentrations and temperatures. Stainless steel is an excellent acetic acid resistant material. 316 stainless steel containing molybdenum can also be used in high temperature and dilute acetic acid steam.

High alloy stainless steel or fluoroplastic pump can be selected for high temperature and high concentration acetic acid or other corrosive medium. Such as CQB magnetic pump, CQ stainless steel magnetic pump.

5 alkali (sodium hydroxide)

Generally corrosive is not very strong, but the general alkali solution will produce crystallization, so can choose to configure graphite silicide 169 material mechanical seal FSB type fluoride alloy alkali pump.

6 ammonia (ammonia hydroxide)

Most metals and nonmetals corrode slightly in liquid ammonia and ammonia (ammonia hydroxide), and only copper and copper alloys are not suitable for use. At this time, choose CQF engineering plastic magnetic pump, FSB fluorine alloy centrifugal pump is better.

7 brine (seawater)

The corrosion rate of ordinary steel in sodium chloride solution, sea water and salt water is not very high, so it is generally necessary to use coating protection; all kinds of stainless steel also have very low uniform corrosion rate, but may cause local corrosion due to chloride ions, usually 316 stainless steel is better.

8 alcohols, ketones, esters, ethers

Common alcohols are methanol, ethanol, ethylene glycol, propanol and so on, ketones are acetone, butanone and so on, esters are all kinds of methyl ester, ethyl ester, ether medium has methyl ether, ether, butyl ether and so on, their corrosiveness is basically not strong, so can choose ordinary stainless steel, specific selection should also be based on the properties of the medium. Make reasonable choices with relevant requirements.

In addition, it is noteworthy that ketone, ester, ether are soluble to a variety of rubber, in the selection of sealing materials to avoid mistakes. It is suggested to choose inorganic sealed fluoroplastic magnetic pump.

There are many other media can not be introduced here one by one, in short, must not be arbitrary and blind in the selection of materials, should be more relevant information or learn from mature experience.

]

Note two: seal problem

Leakage-free is the eternal pursuit of chemical equipment, and it is this requirement that contributes to the increasing application of magnetic pump.

However, there is still a long way to go to truly achieve leak-free, such as magnetic pump isolation sleeve life problems, material corrosion problems, the reliability of static seals and so on.

Some basic facts about sealing are briefly introduced as follows:

1 sealed form

For static seal, there are usually only two kinds of seal gasket and seal ring, and seal ring O ring is the most widely used.

For dynamic seal, chemical pump seldom uses packing seal, mainly mechanical seal, mechanical seal has single end face and double end face, balance type and non-balance type, balance type is suitable for high pressure medium seal (usually refers to pressure greater than 1.0 MPa), double end face machine seal is mainly used for high temperature, easy crystallization, viscosity, containing particles. As well as toxic volatile media, double-face machine seal should be injected into the sealing chamber isolation fluid, the pressure is generally higher than the medium pressure of 0.07 ~ 0.1 MPa.

2 sealing material

The materials for static sealing of chemical magnetic pumps are usually made of fluorine rubber.Using PTFE materials; mechanical seals dynamic and static ring material configuration is more critical, not the best cemented carbide to cemented carbide, high price is on the one hand, there is no hardness difference between the two is not reasonable, so it is best to distinguish according to the characteristics of the medium.

(Note: The typical configurations of mechanical seals and pipeline systems in API 610, eighth edition, are specified in Appendix D)

]

Note three: viscosity problem

The viscosity of the medium has a great influence on the performance of the pump. When the viscosity increases, the head curve of the pump decreases, and the head and flow of the optimum working condition decreases, while the power rises, thus the efficiency decreases.

In general, the parameters on the sample are the performance of conveying clear water, when conveying viscous media should be converted (the correction coefficient of different viscosity can be consulted the relevant conversion chart).

For conveying slurry, paste and viscous liquid with high viscosity, it is recommended to use mortar pump.

]

Pump selection principle

When designing equipment and equipment, the design institute must determine the performance and performance parameters of the pump and select the pump type. This choice must start with choosing the type and form of pumps. Then what principles should be used to select pumps? What is the basis?

1. Make the type and performance of the selected pump meet the requirements of flow, head, pressure, temperature, cavitation allowance, suction stroke and other technological parameters.

2, must meet the requirements of media characteristics.

For pumps transporting inflammable, explosive, toxic or precious media, the shaft seal is required to be reliable or non-leakage pump, such as magnetic drive pump (without shaft seal, using isolated magnetic indirect drive);

For pumps transporting corrosive media, corrosion resistant materials such as fluoroplastic corrosion resistant pumps are required for convective components.

For pumps containing solid particle media, wear-resistant materials are required for convective parts, and clean liquid is used for shaft seals when necessary.

3, mechanical requirements require high reliability, low noise and small vibration.

4, correctly calculate the input cost of pump purchase.

5. When transporting strong corrosive medium (such as “ concentrated sulfuric acid, concentrated nitric acid ”), when transporting flammable and explosive medium, and when using environment must not have any pollution, magnetic pump can be used, such as “ CQB series magnetic pump, IMD series magnetic pump, if need self-priming, FZB fluoroplastic self-priming pump can be used.

6. IHF centrifugal pump and FSB centrifugal pump have the characteristics of high rotational speed, small volume, light weight, high efficiency, large flow rate, simple structure, no pulsation of infusion, stable performance, easy operation and maintenance, etc. If there is no special requirement in use, centrifugal pump is better.

7. Transport of chemical media containing solid particles pump, convective components required wear-resistant materials: UHB mortar pump is the best choice, UHB corrosion-resistant and wear-resistant mortar pump material for high-strength new engineering plastics UHBWPE, it is a modified ultra-high molecular weight (more than 5 million) polyethylene. In plastics, it has excellent wear resistance, experimental comparison, its wear resistance is far higher than stainless steel, and impact resistance, creep resistance and excellent corrosion resistance (similar to F4), as well as non-adhesion and other unique properties.

8. When the medium level is below the pump installation position: FZB fluoroplastic self-priming pump should be selected, if the characteristics of magnetic pump need to be satisfied, ZMD fluoroplastic self-priming magnetic pump can be selected.

9. Choose the best type according to the pump performance curve: When the use requirements can not find the right type in the performance parameter table, refer to the pump performance curve to select the most suitable pump type.

]

How to select these kinds of situations?

1 conveying acid water containing solid particles, which pump should be chosen?

Q: The medium we need to transport is a little corrosive (acidic water), which contains about 20% of the solid particles. Would you like to choose a corrosion-resistant and wear-resistant pump?

Answer: If the corrosiveness is not very strong, you can choose UHB-ZK series of corrosion-resistant and wear-resistant mortar pump, its internal overflow components are all made of ultra-high molecular weight polyethylene with good corrosion resistance and wear resistance, can transport medium with solid content not more than 40%, corrosive, and long service life, simple maintenance.

If corrosiveness is very strong, fluoroplastic centrifugal pumps should be selected to provide corrosion resistant and wearable machine seals.

2 our medium temperature is very high, corrosiveness is very strong. What pump is it good for?

Question: We need to transport medium temperature is very high (about 140 degrees), very corrosive (glacial acetic acid), we want to choose a leak-free, corrosion-resistant pump, what pump to choose?

Answer: IMD high-temperature fluoroplastic magnetic pump is recommended, the specific material is: pump shell fluoroplastic alloy (F4/F46), impeller, isolation sleeve and other components using PFA (soluble PTFE), can withstand temperature up to 180 degrees, and good corrosion resistance.

3 the corrosive medium of transportation is very strong. What pump should be chosen?

Q: we need to deliver the medium to the aqua regia. At normal temperature, what pump should we choose?

A: fluoroplastics pump is recommended. Fluoroplastics are one of the best corrosion resistant materials nowadays.

4 the corrosive medium of the conveying medium is a little strong. What pump should be chosen?

Question: We need to transport 30% hydrofluoric acid, the temperature is about 40 degrees, which pump to choose?

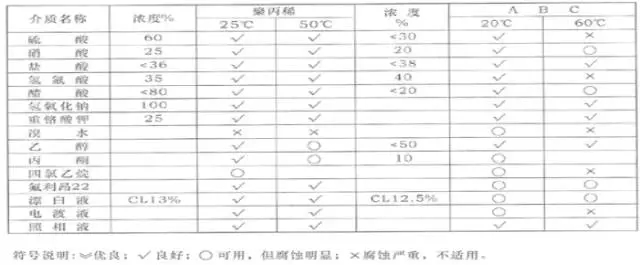

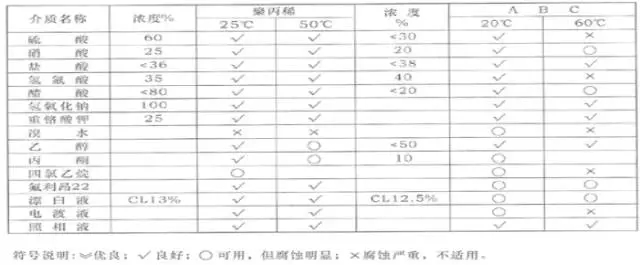

Answer: Can choose engineering plastics (reinforced polypropylene) pump, engineering plastics pump can transport the media range as follows:

If the media are available in the above table, the following engineering plastics pumps are listed below.

1, CQF type engineering plastic magnetic pump

2 、 FUH engineering plastics centrifugal pump

3 、 QBY engineering plastics pneumatic diaphragm pump