Abstract: With the rapid expansion of the city, the sewage volume in the city increases gradually, accompanied by the increase of sludge production. This paper mainly introduces the application of paddle dryer in sludge drying treatment, analyzes its related technology and economic benefits, and expounds the relative advantages of paddle dryer in sludge drying treatment, hoping to be helpful to relevant professionals.

Key words: paddle dryer; sludge drying; application

With the rapid development of economy, the process of urbanization in China is accelerating. Rapid expansion of the city will inevitably be accompanied by the increase of urban sewage volume, at the same time, sludge production will also increase substantially. According to statistics from the environmental protection department, as of 2010

At the end of the year, the number of municipal sewage treatment plants in China was 2,881, and the capacity of sewage treatment could reach 12.33 million tons per day, and the annual sewage treatment capacity could reach 33.72 billion tons. According to the moisture content of 80%, the amount of sludge produced in cities in China can reach 30 million tons per year. Therefore, it is very necessary to take reasonable measures to treat the sludge harmlessly and reduce the amount of sludge for the environmental protection of our country.

1. the necessity of sludge drying.

There are many ways to deal with sludge. The main methods discussed in this paper include landfill, incineration, drying and so on. In the actual sludge treatment, which treatment method should be selected needs to consider the water content of sludge comprehensively. The sludge with water content less than 50% is usually incinerated. If the water content is below 60%, composting method is generally used in the process of sludge treatment. For municipal sludge, the sludge produced by the sludge moisture content is high, before treatment should be first through mechanical dewatering, generally after dewatering its moisture content is still around 80%, so sludge drying for the treatment of municipal sludge has very important significance and value. Sludge drying process has become one of the most important links in sludge treatment. Only sludge drying can ensure the smooth progress of the sludge treatment process. Therefore, sludge drying is very important for sludge treatment.

2. blades ten dryness machine introduction

Paddle dryer is a horizontal stirring equipment which is used for drying through heat conduction. It mainly consists of several parts: thermal axis, fuselage, end plate, upper cover and transmission system.

The working principle of the dryer is that the medium types of the dryer include steam, hot water and heat conducting oil, etc. A rotating joint is installed at the shaft end of the dryer to guide people to derive heat medium. Normally, the heating medium is fed into the shell jacket and the inner cavity of the blade shaft respectively from two ways. At the same time, the body and the blade shaft are heated, and the material is dried by conducting heat. After drying, the material is continuously and quantitatively delivered to the feeding port of the dryer through the screw feeder. After entering the dryer, the material is rotated and stirred by the blade. The heating interface and the body and the blade are constantly contacted so that the material is fully heated so that the moisture of the material can be fully steamed. Hair. At the same time, with the selection of blade shaft, the material is spiral to the direction of the outlet, in the process of transportation is still in the state of stirring, the moisture in the sludge is still constantly evaporating. Until the end, the dry qualified material is discharged from the discharge port.

The characteristics of the blade dryer are as follows: low energy consumption, full use of heat, safe and reliable operation, small equipment volume, low operation and maintenance costs, self-purification ability and strong drying particle movement regularity.

Application of 3. paddle dryer in Engineering

3.1 introduction to engineering

This project is aimed at a sludge drying treatment project. The project covers an area of 2800 ni, the sludge volume is 300 tons per day, the sludge moisture content is about 80% before treatment, the sludge moisture content is about 20% after treatment, and the equipment used in the sludge drying process is 3 paddle dryer. The machine can process 100 tons of sludge per day. The heat source used in the process of the equipment is the steam burned by the power plant near the sludge treatment plant. The dried sludge is sent to the power plant for power generation, so that the sludge can be treated more scientifically.

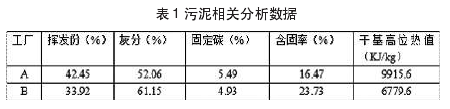

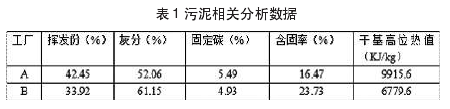

The sludge treated by this project is mainly the sludge produced by the municipal sewage treatment plant. Due to the influence of geographical environment and living environment, the sludge treated by this project has a large amount of sediment and a relatively low content of organic matter. The data of the sludge treated by this project are as follows: the influence of geographical environment and living environment, the sewage treated by this project. The sediment concentration is relatively large and the content of organic matter is relatively low. The data of sludge disposal are shown in Table 1.

3.2 sludge drying process description

The sludge drying process in this project includes water-bearing sludge storage and transportation system, drying treatment system, dry sludge storage and transportation system, odor treatment system, electrical system and automatic control system. The drying treatment system is mainly composed of three paddle-type sludge drying production lines. Each paddle-type sludge drying production line mainly includes: a paddle-type dryer, a carrier gas circulating fan and a carrier gas scrubbing tower, etc.

The actual operation of paddle sludge drying treatment line is as follows:

Firstly, the sludge is stirred and vibrated strongly by the blade of the dryer after it is brought into the blade dryer through the storage and transportation system, and the moisture in the sludge evaporates rapidly through the rapid heating of the interface of the machine.

Secondly, through the role of circulating fans in the system, the air as carrier gas flows through the blade dryer at a faster speed, thus bringing water out of the system, ensuring that the sludge moisture can be quickly evaporated and diffused;

Thirdly, the carrier gas after the blade dryer discharged through the scrubbing tower for Zaguan treatment, the main purpose is to carry out the carrier gas containing a large amount of steam and a small amount of dust removal;

Fourthly, after the above steps, the carrier gas is partly recycled through the blades in the dryer, and part of the carrier gas is to be processed into the deodorization system.

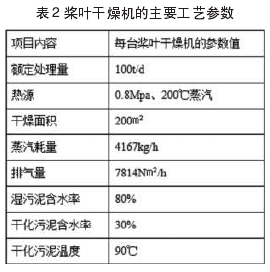

3.3 main parameters of paddle dryer

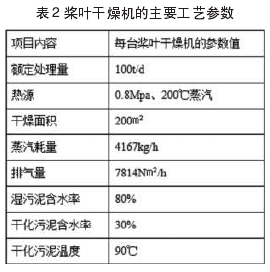

Under this technological conditionThe main technological parameters of paddle dryer are shown in Table 2.

3.4 operation cost analysis of drying system

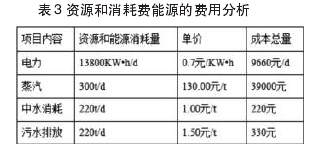

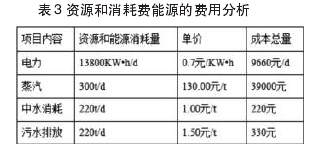

According to the analysis of the relevant resources and energy consumption requirements during the operation of the drying process, the cost of resources and energy consumption is about 49210 yuan / / d, and the cost of resources and energy consumption per ton of wet sludge in the drying process is about 164 yuan. The cost analysis of specific resources and energy consumption is shown in Table 3.

Summary of application of 3.5 impeller dryer in sludge drying project

Through the successful application of paddle dryer in sludge drying project, it can be concluded that paddle dryer has great technical and economic advantages in sludge drying treatment, mainly including the following aspects:

Firstly, the sludge drying system of paddle dryer runs smoothly, safely, and has high reliability. It can reduce the sludge to the greatest extent. At the same time, the pollutant discharge after treatment can meet the requirements of relevant discharge standards.

Secondly, through the analysis of the operation cost of the drying treatment system of the blade dryer, it can be seen that the project adopting this technology has lower investment cost and operation cost, and occupies a small area, and the energy consumption is very low.

Thirdly, the management of sludge drying treatment is relatively simple, convenient, and has a more flexible mode of operation, which can flexibly adjust the specific mode of operation and related parameters according to seasonal differences, different working environment temperatures (eventually resulting in changes in the nature and quantity of sludge);

Fourthly, this kind of sludge drying treatment can easily realize the automatic control of sludge treatment process, thus greatly improving the management level.

Fifth, the blade dryer mainly uses steam as its power and heat source. The operation of the dryer can be matched with the relevant equipment of waste incineration power plant. It can fully reflect the advanced concept of circular economy, can save resources to the greatest extent, reduce energy consumption to the greatest extent, and conform to the conservation society. Meeting needs.

4 Conclusion

With the continuous development of our society, people's living standards have been significantly improved. Sludge treatment has attracted wide attention. How to improve the capacity of sludge treatment and achieve environmental protection of sludge treatment has become the goal of modern urban sludge treatment. Paddle dryer has low energy consumption, relatively small equipment volume, stable operation in actual work, and has a great advantage in sludge treatment. It is precisely for this reason that many municipal sludge treatment choose this equipment. Based on my own work experience, the author discussed the application of paddle dryer sludge drying, hoping to promote the further development of sludge drying in China.