Under the background that the state attaches great importance to the safety of chemical production and promotes the manufacture of 2025 in China, the technology of synthetic microreactions in pharmaceutical and chemical industries has made rapid progress, and the research and development achievements of pharmaceutical-grade and high-throughput microchannel equipment emerge in endlessly.

In response to the national call, Zhongshan Zhian Chemical Technology Co., Ltd. has developed a three-dimensional shear microchannel multifunctional reactor. The success of this technology depends on the unique structure and effect of 3D printing, which greatly changes the mixing and shearing efficiency of microreactions.

A super-difficult 3-pump continuous 2-step ultra-low temperature reaction was conquered in Wuhan and Zhongshan Zhian Chemical Technology Co., Ltd. with a micro-channel platform, and new breakthroughs were made in flow, temperature, pressure and precise feeding.

It is understood that the reaction process as shown above, all three groups of raw materials are flammable, containing polar solvents and strong alkalinity. If the traditional equipment reaction conditions, in - 60 - 90 C reaction, and the main products, by-products, salt, intermediate products can not be stored at room temperature.

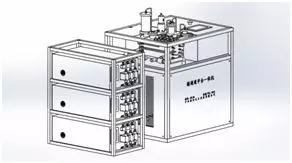

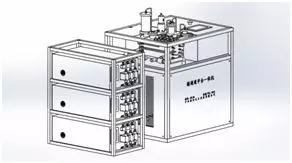

Reaction core equipment consists of three parts.

The first three-dimensional shear pipe reactor with independent intellectual property rights was used in the first three-dimensional shear pipe reactor in the world. The material is nickel-based alloy and cobalt-chromium-molybdenum alloy. The total length of the reactor is 1 m and the total residence time of the two steps is 3-50 seconds.

In the second part, the ZA2000 special pump for large flow micro-channel is different from the general advection pump. The pump can operate at 10-2000 ml/min high pressure (maximum operating pressure 13 mpa), corrosion-resistant and long-term, with very low pulse and minimum flow deviation of 0.2-0.5%.

In the third part, the automatic control platform of constant temperature and interlocking adopts the micro-reverse integrated machine. The model is ZSMR2600. The constant temperature range is -30-200 C, the system pressure is 10 mpa, the maximum flow rate is 600 ml/min, and the maximum effective annual output is 50 tons.

The experimental process is as follows: the material is pre-cooled by a thermostat, fed by pumps A, B and C, and controlled at 0 ~20 C. After two ZSMR15 alloy 3D reaction tubes, the material enters the receiving tank. The experimental data show that under the condition of 200-400 ml/min flow rate, with the cooperation of 3D reaction tube, large flow microchannel special pump, chain control system and process scheme, the reaction can be completed in 10-50 seconds, which changes the large flow pilot scale of ultra-low temperature and continuous two-step reaction, and the yield and unit consumption data can reach the yield of traditional reaction conditions.

It is understood that Zhongshan Zhian Chemical Technology Co., Ltd. has adopted a complete set of technology and differentiation strategy for industrial micro-reactor equipment. 3D micro-channel has been successfully validated in a large flow rate of gas-liquid reaction, liquid-liquid reaction and heterogeneous reaction of various pharmaceutical and pesticide intermediates. At the same time, the equipment can also carry out industrial amplification with larger flow rate. The reaction speed and effect are more pertinent and applicable than imported equipment, and the cost of technological transformation is low.

Some pre-industrial experimental cases:

_3 pump feed, 200 ml/min reaction time 2 minutes, 98% conversion of raw materials;

_2 pump feeding, 40ml/min, 50 seconds reaction all conversion;

_2 pump feeding 120 ml, 0.5 seconds 60%;

_2 pump feed, 90 ml/min feed, stay 25 seconds, raw material conversion 70%;

_2 pump feed acylation, equal molar feed, 200 ml/min, 30 seconds, conversion 98%;

_High pressure saponification, time reduced by 95%;

_Dimethyl sulfate etherification, flow rate 1200ml/min, main output 94%, by-product 5%.

At present, Zhongshan Zhian Chemical Technology Co., Ltd. provides 100-500ml/min process validation free of charge for user enterprises.

Provide a full range of micro-reactor equipment door-to-door service

First free service reservation: 5 in Jiangsu and 5 in Zhejiang! First come first served!

The experiment lasted only one day, not more than two days at the longest.

Apply to

_Exothermic ultra-low temperature reaction modification;

Nitrification, diazotization, hydrogenation and reduction;

_Low temperature, high temperature, controlled reaction.

Reaction speed, residence time and equipment volume all break through your experience.